Device for measuring highest strength ratio of slurry retaining wall by simulating different working conditions and operation method

A mud retaining wall, the highest strength technology, applied in the direction of foundation structure engineering, foundation structure test, sheet pile wall, etc., can solve the problems of material waste and inability to effectively target the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

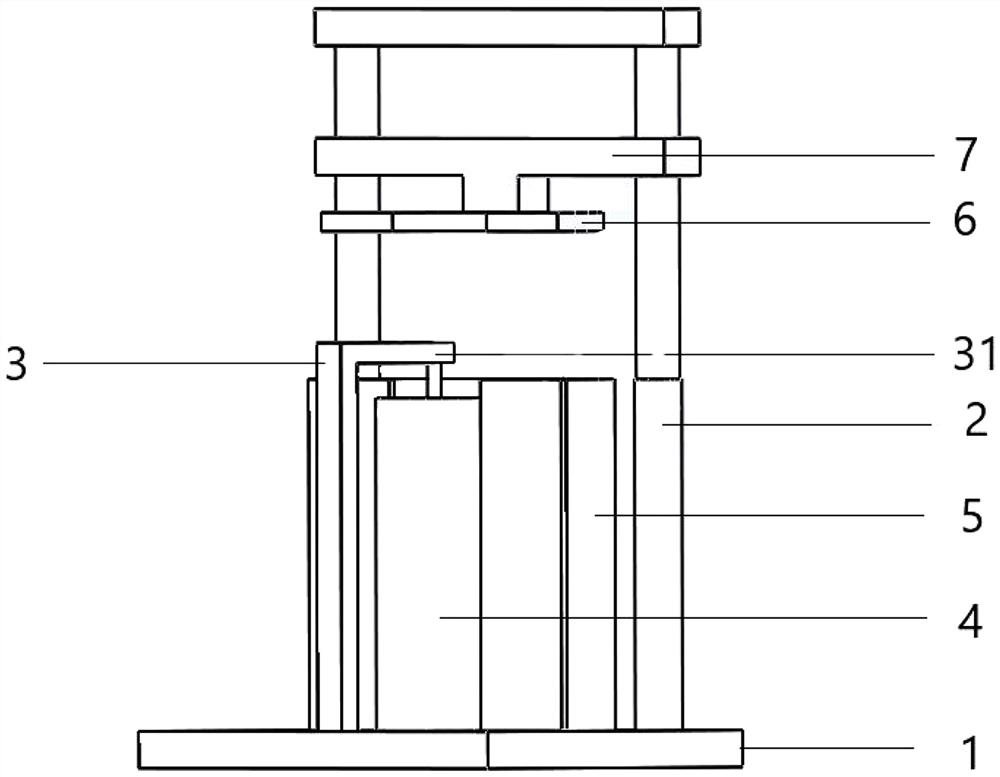

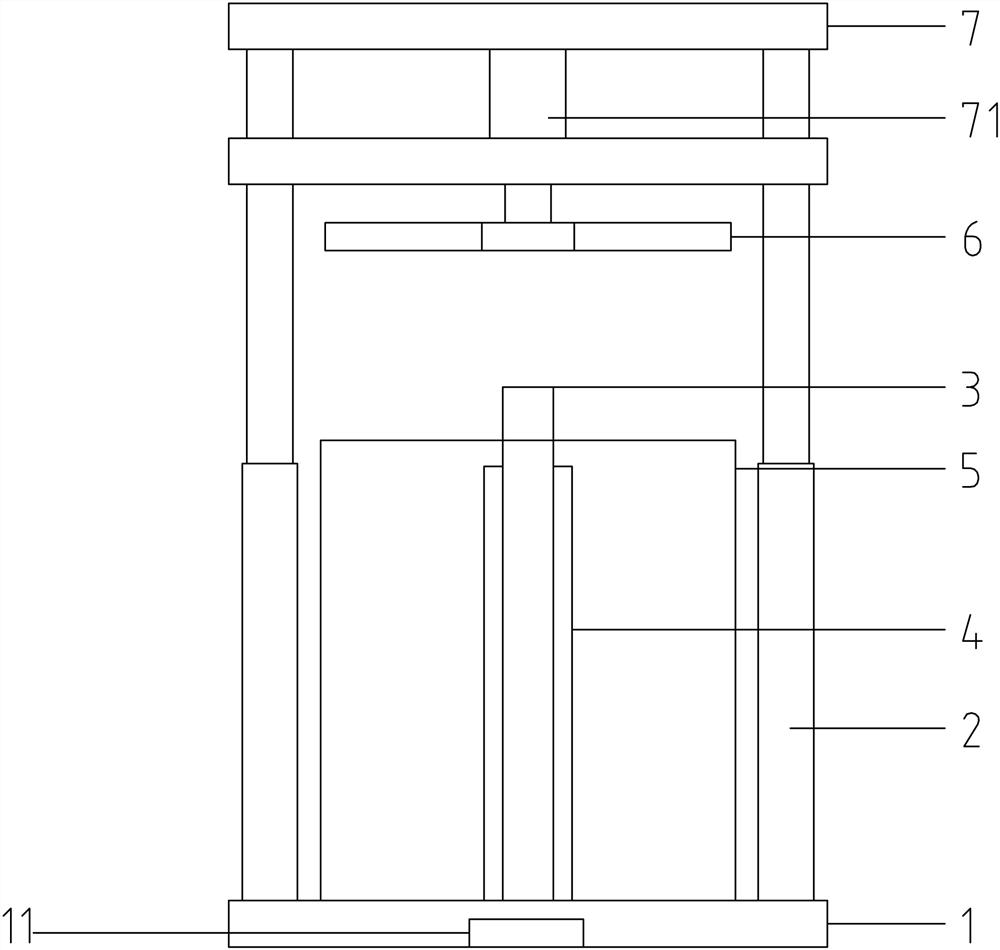

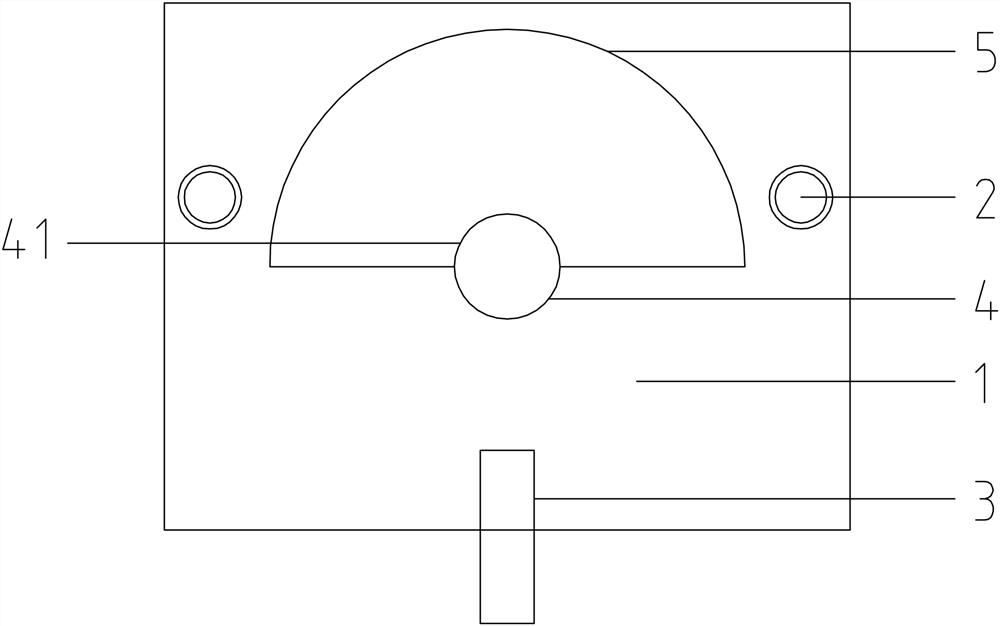

[0058] see Figure 1-11 , a device for simulating different working conditions to measure the highest strength ratio of the mud retaining wall, which includes a bottom cap 1, an inner mud tube 4 and an outer half cylinder 5, the inner mud tube 4 is fixedly installed in the middle of the bottom cap 1, The outer semi-cylinder 5 is fixed on the bottom platform 1, and is arranged on the periphery of the inner mud tube 4 so that the two are arranged concentrically; on the bottom platform 1, a shaft column is symmetrically arranged on the outer side of the outer semi-cylinder 5 2; a mixer support 3 is fixed on the bottom platform 1, a mixer 31 is fixedly installed on the top of the mixer support 3, a reaction force frame 7 is fixed on the top of the shaft column 2, and the bottom of the reaction force frame 7 A hydraulic jack 71 is fixed at the central part, and a pressure plate 6 is installed at the bottom end of the piston rod of the hydraulic jack 71; a strain gauge is inserted a...

Embodiment 2

[0072] For simulating foundations of different depths, the earth pressure generated by the foundation at that depth is roughly calculated according to the specifications, the pressure is increased at the deep part of the simulated foundation, and the shallow part of the simulated foundation is properly pressurized or not pressurized; different materials can be added to the outer half cylinder, Add coral sand, suitable for coral sand foundation, add sand, suitable for gravel foundation.

[0073] An operation method of a device for simulating different working conditions and measuring the highest strength ratio of mud retaining wall, characterized in that it includes the following steps:

[0074] S1: Place the device on a flat ground, place the outer semi-cylinder 5 on the bottom cap 1 of the device, put the inner mud tube 4 in the middle of the bottom cap 1, and connect with the outer semi-cylinder 5, choose the appropriate one according to the required radian of the retaining w...

Embodiment 3

[0085] For the visualization of the device, the inner mud cylinder 4, the outer semi-cylinder 5 and the pressure plate 6 steel plates are all made of tempered glass, and the whole process of the operation is photographed and observed, including the change of the semi-cylinder when coral sand is added, and the pressure plate when the pressure is applied. The tightness between coral sands and the trajectory of mud infiltration in the later stage of the mud retaining process, whether it expands from the side or in an arc; cooperate with the arc camera device 8 to measure the uniformity of mud infiltration, and obtain its average influence range and The maximum and minimum influence ranges can be selected according to the needs.

[0086] A construction method of a device for simulating foundation pressurization to measure the highest strength ratio of mud retaining wall, which is characterized in that it includes the following steps:

[0087] S1: Place the device on a flat ground,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com