Herbicide, herbicide water dispersible granule and preparation method thereof

A technology for dispersing granules and dispersing agents, applied in herbicides and algaecides, botanical equipment and methods, chemicals for biological control, etc. Or the problem of residual poisoning of subsequent crops, uneven application of pesticides, etc., to effectively control weeds in the field, avoid phytotoxicity, and achieve excellent herbicidal efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

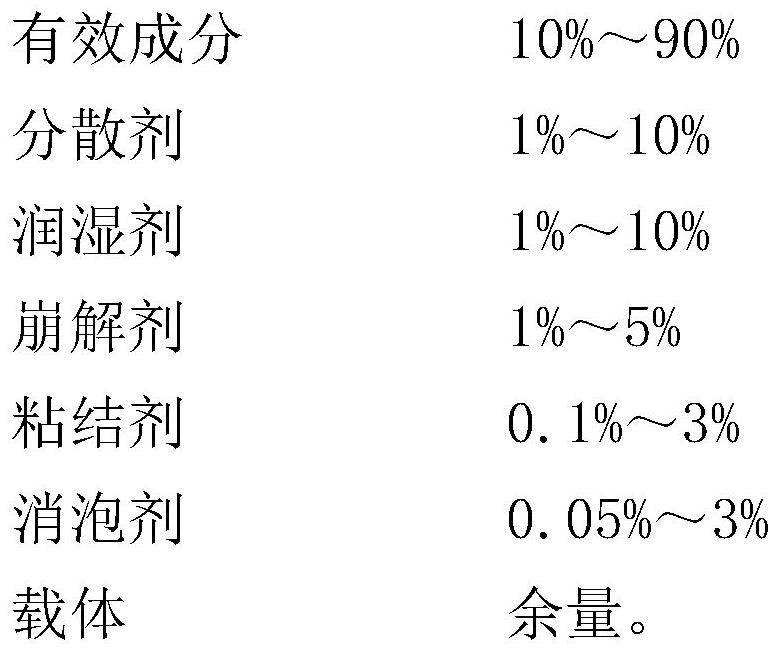

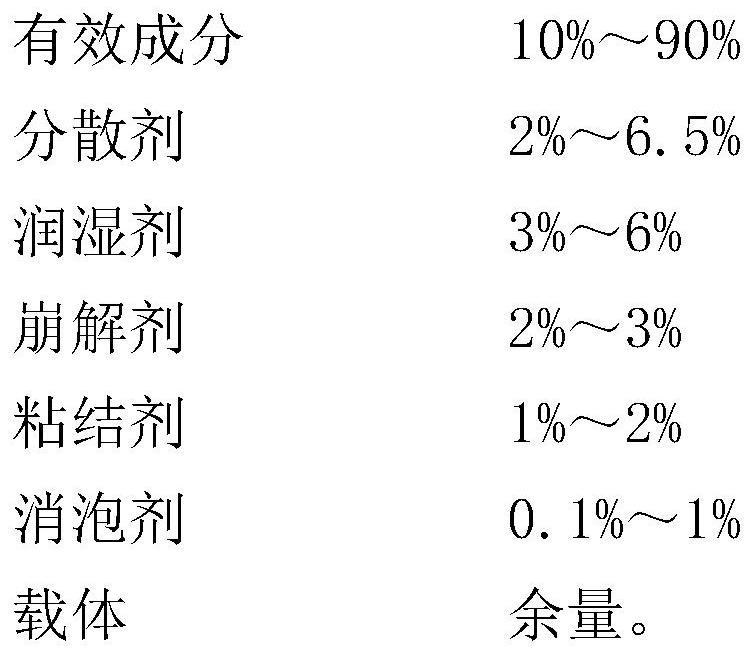

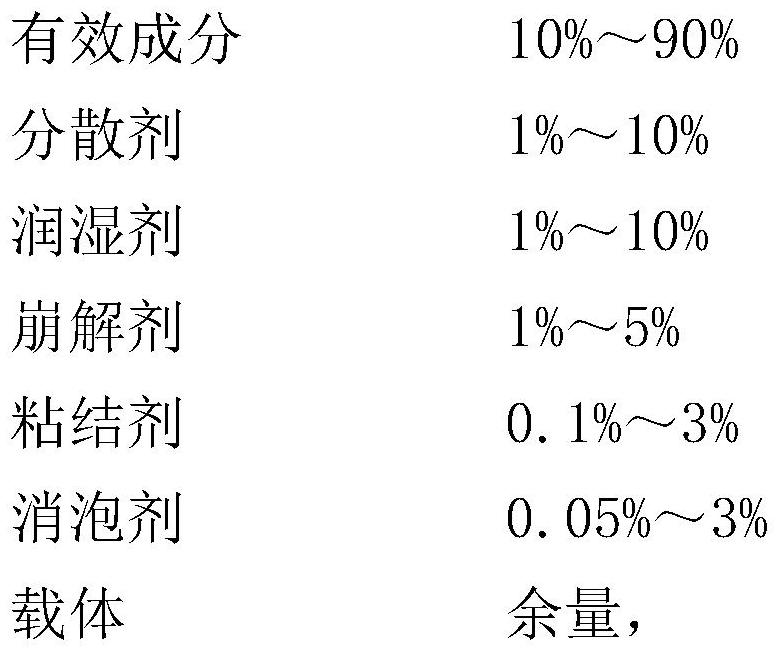

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of water-dispersible granules with a total content of 10% of terbuthiauron and pyriflux

[0035] Weigh each component according to the following proportions: terbuthiauron and pyrizachlor-carbamide according to the mass ratio of 9:1 (9%+1%), dispersant lignosulfonate 3.0%, wetting agent fatty alcohol polysaccharide 3.0% of oxyethylene ether, 2% of disintegrant urea, and 80% of kaolin are put into a mixer and fully mixed, then pulverized by a jet mill, and pulverized to an ultrafine powder with a particle size of ≤10 μm to obtain a pulverized mixed material;

[0036] In the mixed material, add the solution of binder polyethylene glycol 1.0%, silicone defoamer 1% and water (15% of the mixed material quality after crushing), knead for 15 minutes; The material is extruded and granulated, and the wet granules are dried in a boiling dryer at 100-110°C until the water content is less than 2%, to prepare 10% terbuthiauron and pyrizachlor water-dispersible...

Embodiment 2

[0037] Example 2: Preparation of water dispersible granules with 20% total content of terbuthiauron and pyriflux

[0038] Weigh each component according to the following proportions: terbuthiauron and pyrizachlor-carbamide according to mass ratio 8:2 (16%+4%), dispersant lignin naphthalene sulfonate formaldehyde condensate 4.5%, wetting 5.0% alkylnaphthalene sulfate, 2.5% disintegrating agent starch, 65% light calcium carbonate, put into the mixer and mix well, then pulverize through the airflow mill, pulverize to ultrafine powder with particle size ≤ 10μm, and obtain pulverized post-mixed material;

[0039] In the mixed material, add the solution of binder polyethylene glycol 2.0%, silicone defoamer 1% and water (20% of the mixed material quality after crushing), knead for 15 minutes; The material is extruded and granulated, and the wet granules are dried in a boiling dryer at 95-105°C until the water content is less than 2%, so as to obtain 20% terbuthiauron and pyrizaflun ...

Embodiment 3

[0040] Example 3: Preparation of water-dispersible granules with a total content of 40% of terbuthiauron and pyriflux

[0041] Weigh each component according to the following proportions: terbuthiauron and pyrifluzan according to the mass ratio of 4:1 (32%+8%), dispersant polyoxyethylene polyoxypropylene ether 5.0%, wetting agent Diisooctyl sodium sulfosuccinate 6.0%, disintegrant glucose 3%, talcum powder 43%, put into a mixer and mix well, then pulverize through a jet mill, and pulverize to an ultrafine powder with a particle size of ≤10 μm to obtain Mixed materials after crushing;

[0042] In the mixed material, add the solution of binder polyvinyl alcohol 2.0%, organic silicon defoamer 1% and water (25% of the mixed material quality after pulverizing), carry out kneading 15 minutes; The wet material after kneading , carry out extrusion granulation, the wet granules are dried in a boiling dryer at 85-100°C until the water content is less than 2%, and 40% terbuthiauron and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com