Structure used for closing up garbage bag on garbage can and manufactured garbage can thereof

A technology for garbage cans and garbage bags, applied in the field of garbage cans, can solve the problems of high production cost, cumbersomeness, unsanitary contact of garbage at zero distance, etc., and achieve the effect of good collection effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

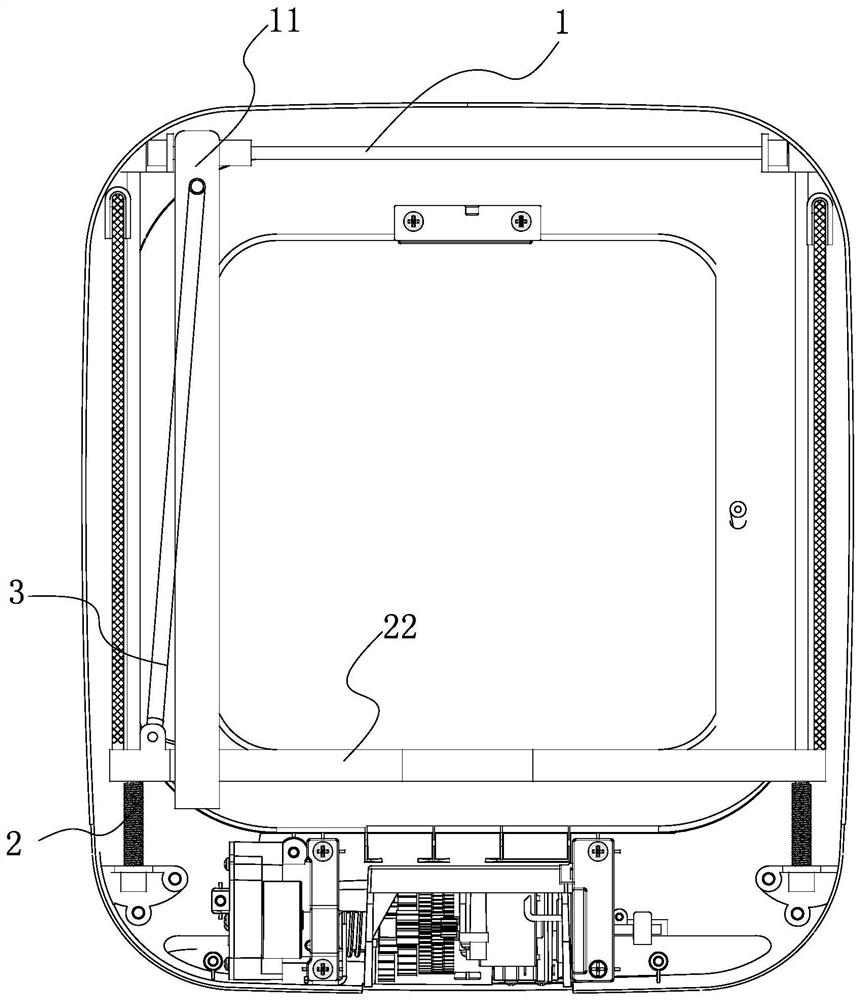

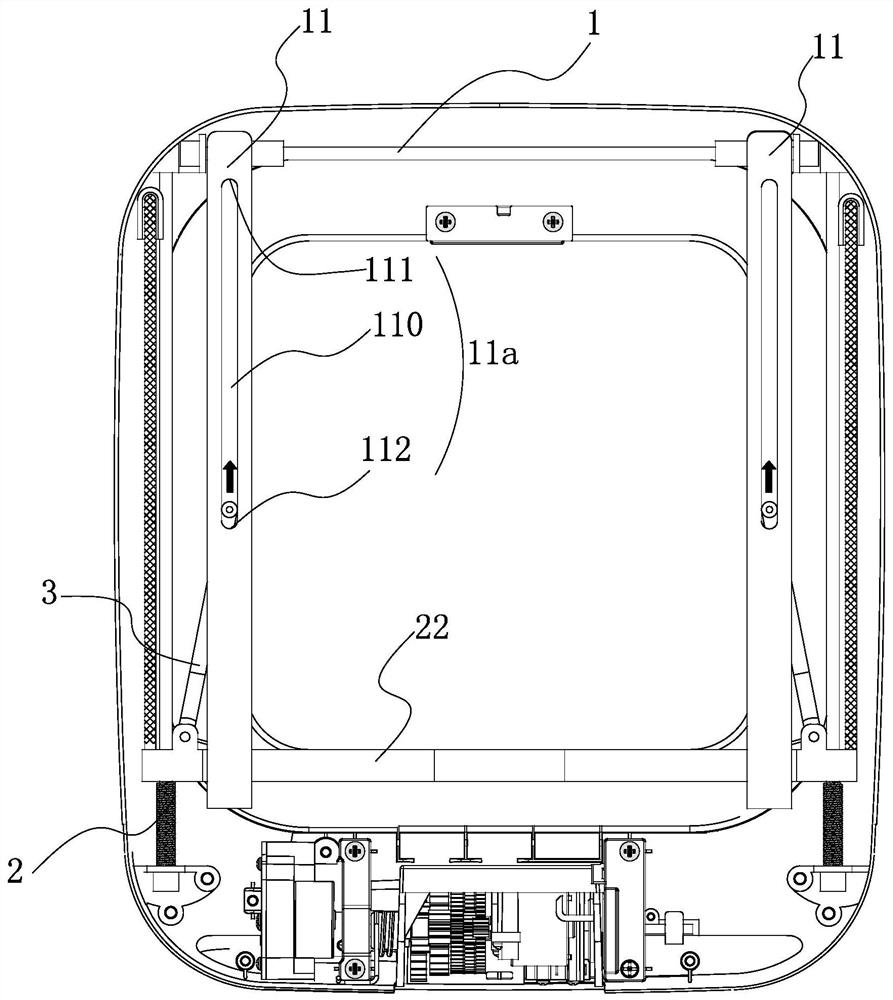

[0047] Such as figure 1 As shown, the structure for closing the mouth of the garbage bag on the garbage can includes a first guide rail 1 and a second guide rail 2, the first guide rail 1 is arranged horizontally; the second guide rail 2 is arranged vertically.

[0048] The second guide rail 2 is slidably provided with a second rod 22 , and the second rod 22 slides along the second guide rail 2 . As a preferred embodiment, the second guide rail 2 is a steel bar, the second rod member 22 is provided with a through hole 520, and the second rod member 22 is passed through the second guide rail 2 through the through hole 520, and the two are slidably connected.

[0049] The first guide rail 1 is slidably provided with first rods 11, and the first rods 11 slide along the first guide rail 1 respectively; as a preference, the sliding connection of the first guide rail 1 and the first rod 11 is the same as that of the first guide rail 1. Two rods 22.

[0050] One end of the connecti...

Embodiment 2

[0070] In this embodiment, the same parts as those in Embodiment 1 are omitted from the same text descriptions and given the same reference numerals.

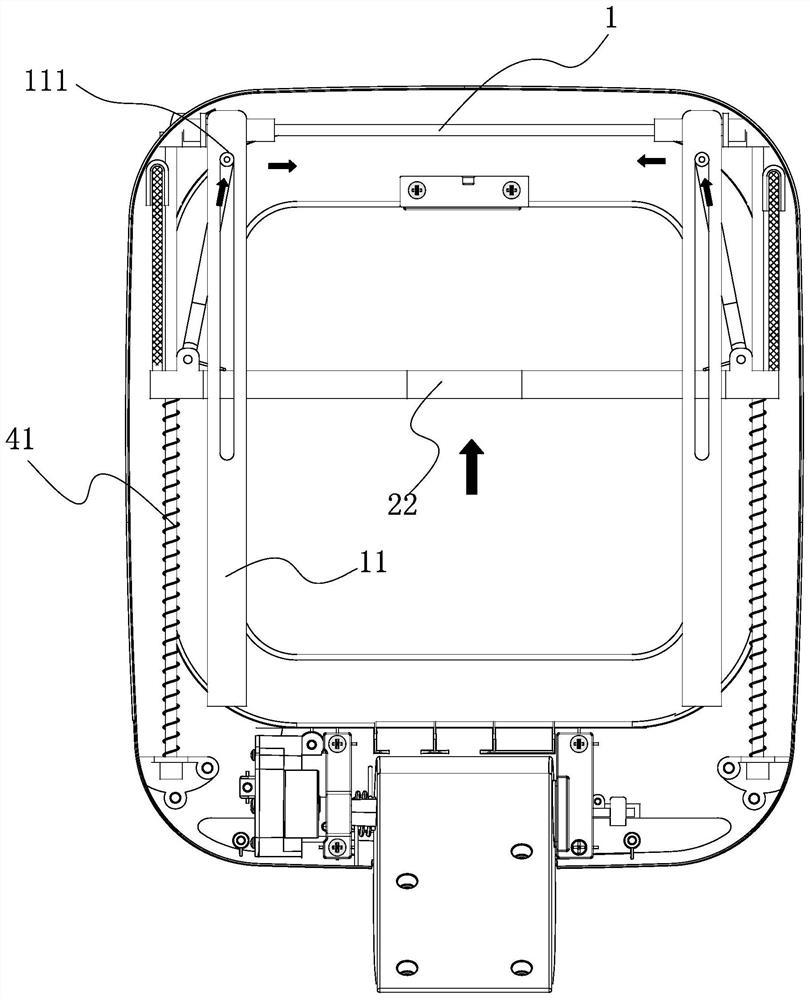

[0071] Such as Figure 7 and Figure 8 As shown, the structure for closing the garbage bag on the garbage can also includes a first guide rail 1, a second guide rail 2, and a transmission device. The transmission device includes a first transmission wheel 61 , a second transmission wheel 62 and a synchronous belt 63 . The first transmission wheel 61 and the second transmission wheel 62 are covered with a timing belt 63 , and the timing belt 63 is connected with the second rod 22 . The first transmission wheel 61 or the second transmission wheel 62 drives the synchronous belt 63 to move, and the second rod 22 is driven by the synchronous belt 63 .

[0072] In this embodiment, there are two groups of transmission devices. The two sets of transmission devices are located at both ends of the second rod 22 respectively, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com