Steel ruler calibration and measurement method, system and device and storage medium

A technology for calibrating measurement and steel rulers, applied in the field of calibration, can solve problems such as low measurement efficiency, unfavorable geometric measurement requirements for the accuracy of steel rulers, poor accuracy, etc., and achieve the effect of objective and accurate calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

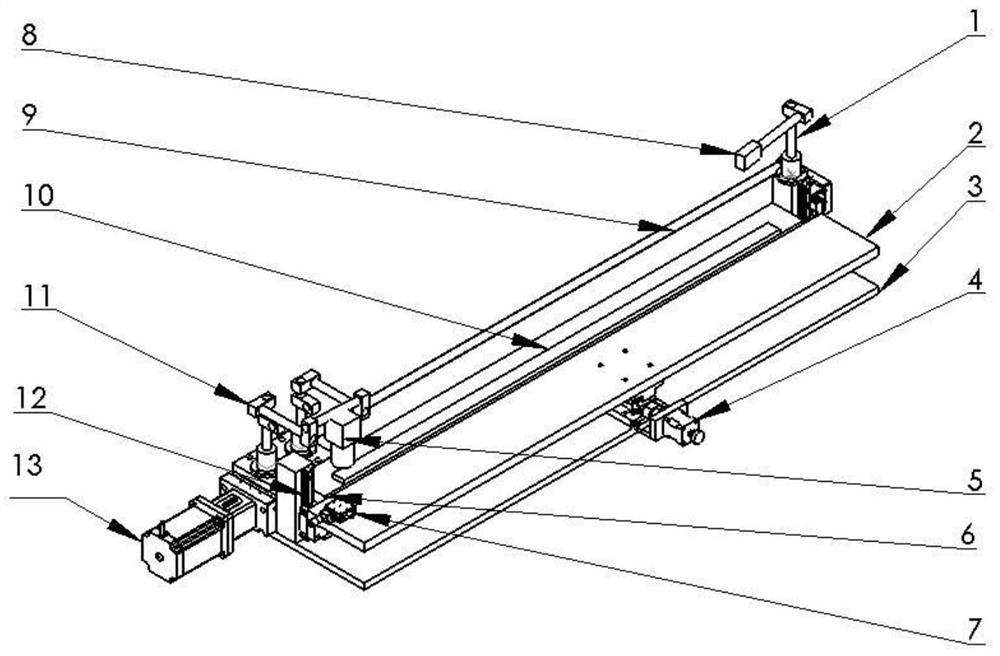

[0041]The present invention will be further described in detail below with reference to the drawings and specific embodiments. For the step numbers in the following embodiments, they are set only for ease of explanation, and there is no limitation on the order between the steps. The execution order of the steps in the embodiments can be adapted according to the understanding of those skilled in the art. Sexual adjustment.

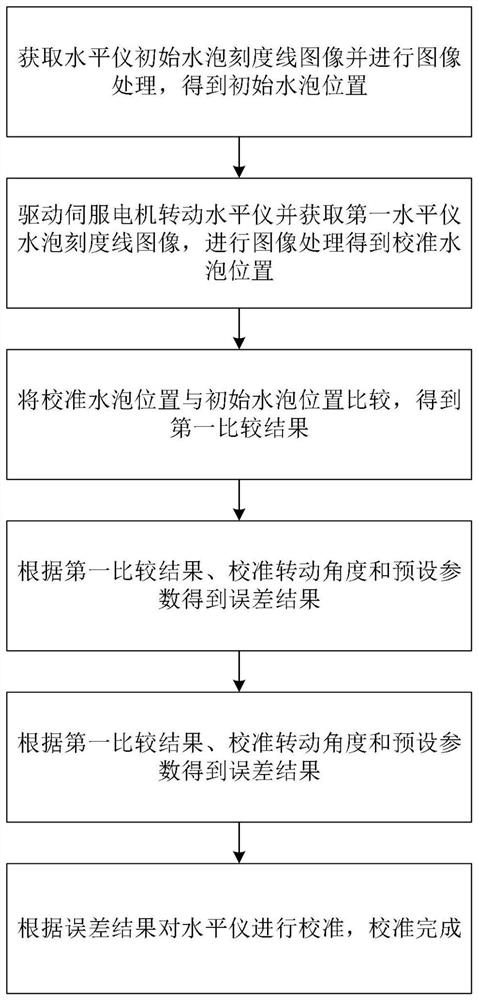

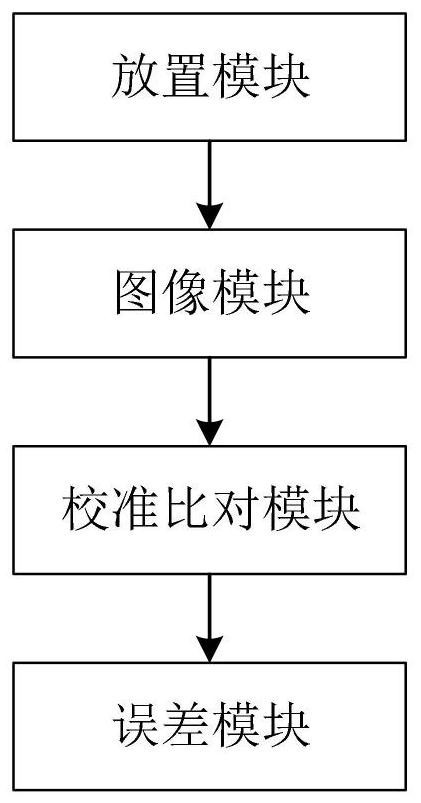

[0042]Referencefigure 1 , The present invention provides a method for calibrating and measuring a steel ruler. The method includes the following steps:

[0043]S1. Place the steel ruler under test on the adjustable measuring table according to the preset rules;

[0044]S2. Obtain the image of the scale line and perform image processing to identify the standard ruler scale and the measured steel ruler scale;

[0045]S3. Obtain the calibration position according to the standard ruler scale and the measured steel ruler scale;

[0046]S4. Read the error of the target position of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap