Semiconductor device and mounting structure thereof

A technology of semiconductor and structure, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of difficult expansion of pads for heat dissipation pads and expansion of heat dissipation area on the surface of wiring substrates, etc. To achieve the effect of ensuring the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

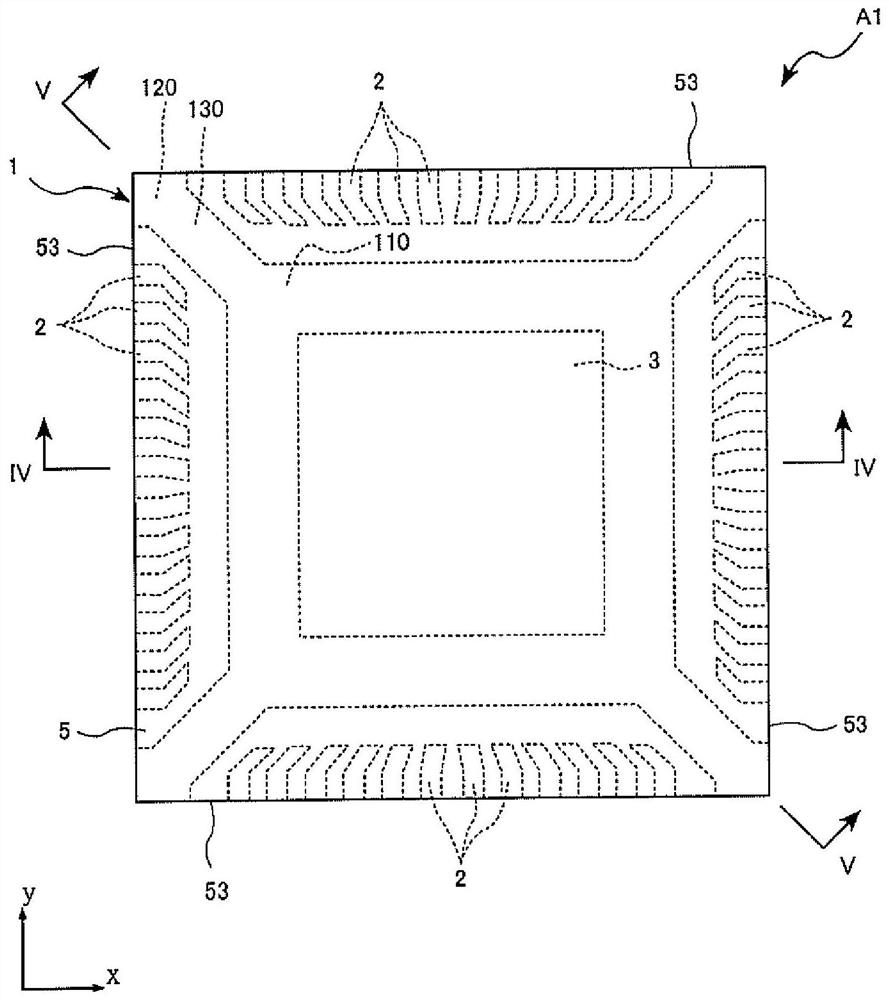

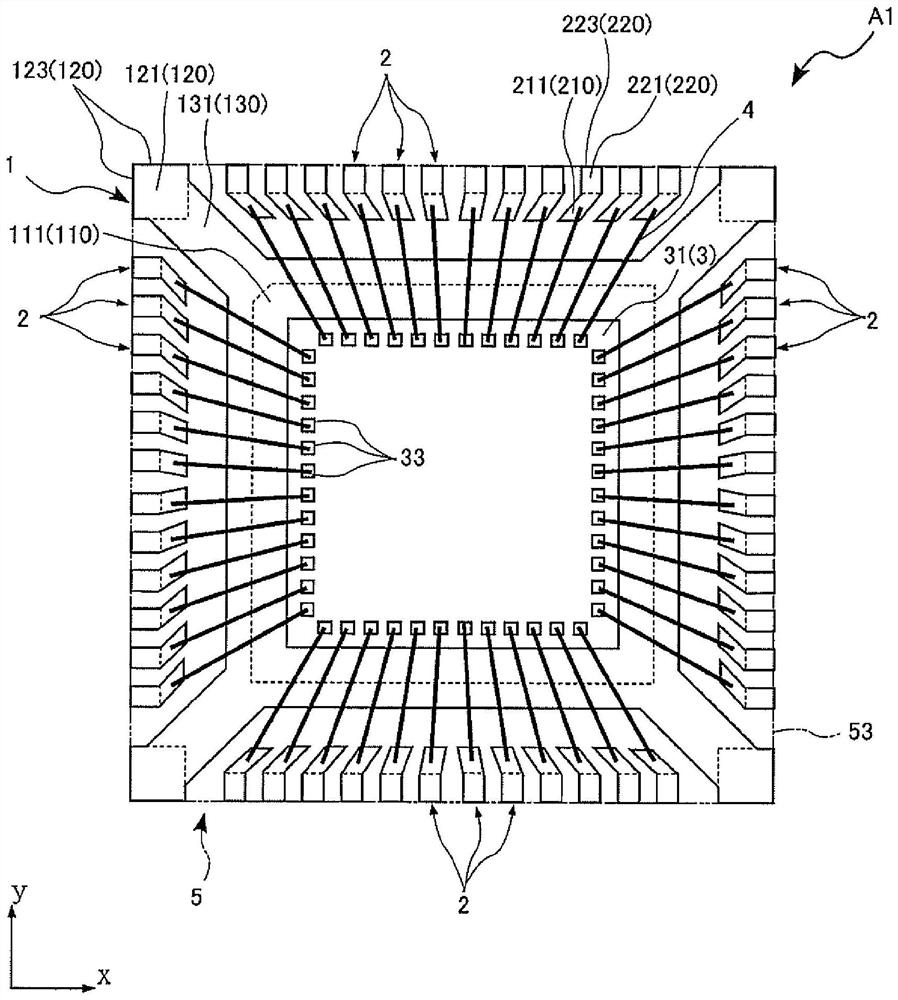

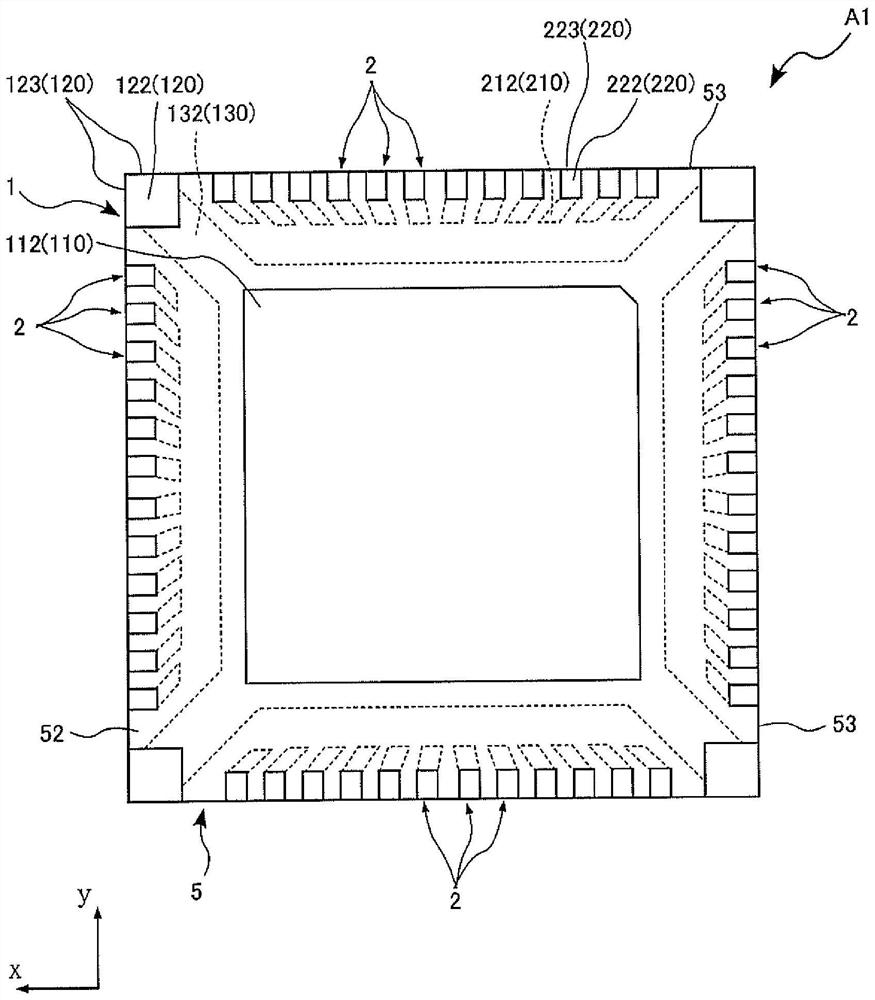

[0034] based on Figure 1 to Figure 6 The semiconductor device A1 according to the first embodiment of the present invention will be described. The semiconductor device A1 includes a first lead 1 , a second lead 2 , a semiconductor element 3 , a bonding wire 4 , and a sealing resin 5 . The semiconductor device A1 is a so-called QFN (Quad Flat Non-leaded package) package.

[0035] figure 1 It is a top view showing the semiconductor device A1. figure 2 It is a plan view showing main parts of the semiconductor device A1. image 3 It is a bottom view showing the semiconductor device A1. Figure 4 is along figure 1 Sectional view of line IV-IV. Figure 5 is along figure 1 Sectional view of the V-V line. Image 6 It is an enlarged plan view of the main part. exist figure 2 and Image 6 In FIG. 2 , for easy understanding, the outer shape of the sealing resin 5 is shown by a phantom line (dash-two dotted line) passing through the sealing resin 5 .

[0036] The semicon...

no. 2 Embodiment approach

[0077] based on Figure 13 and Figure 14 , the semiconductor device A2 according to the second embodiment of the present invention will be described. In these figures, the same reference numerals are assigned to the same or similar elements as those of the semiconductor device A1 described above, and repeated explanations will be omitted.

[0078] Figure 13 It is a bottom view showing the semiconductor device A2, and is the same as that in the first embodiment. image 3 corresponding figure. Figure 14 It is an enlarged sectional view of main parts showing a state in which the semiconductor device A2 is mounted on the wiring board 9, and is the same as that in the first embodiment. Figure 8 corresponding figure.

[0079] The semiconductor device A2 of this embodiment differs from the semiconductor device A1 in that the mounting portion back surface 112 is not exposed from the sealing resin 5 . The thickness (dimension in the z direction) of the mounting portion 110 in...

no. 3 Embodiment approach

[0082] based on Figure 15 and Figure 16 , the semiconductor device A3 according to the third embodiment of the present invention will be described. In these figures, the same reference numerals are assigned to the same or similar elements as those of the semiconductor device A1 described above, and repeated explanations will be omitted.

[0083] Figure 15 It is a bottom view showing the semiconductor device A3, and is the same as that in the first embodiment. image 3 corresponding figure. Figure 16 It is an enlarged cross-sectional view of main parts showing a state in which the semiconductor device A3 is mounted on the wiring board 9, and is the same as that in the first embodiment. Figure 8 corresponding figure.

[0084] The difference between the semiconductor device A3 of this embodiment and the semiconductor device A1 is that the connecting portion back surface 132 is exposed from the sealing resin 5 . The thickness (dimension in the z direction) of the connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com