An autoclaved aerated concrete slab autoclaved curing furnace

A technology of autoclaved curing and autoclaved gas filling, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., which can solve the problems of low efficiency of plate curing and uneven curing of covered plates, so as to avoid uneven steam curing, Uniform effect of steaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

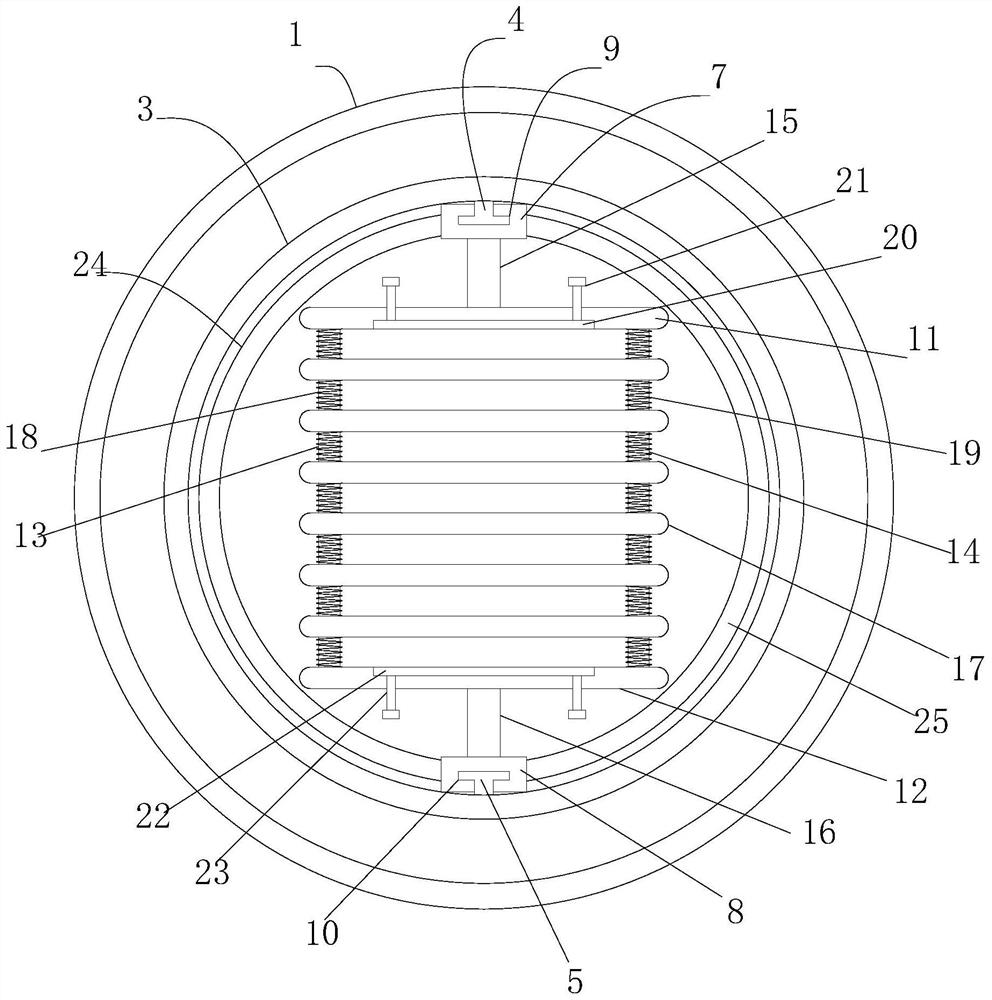

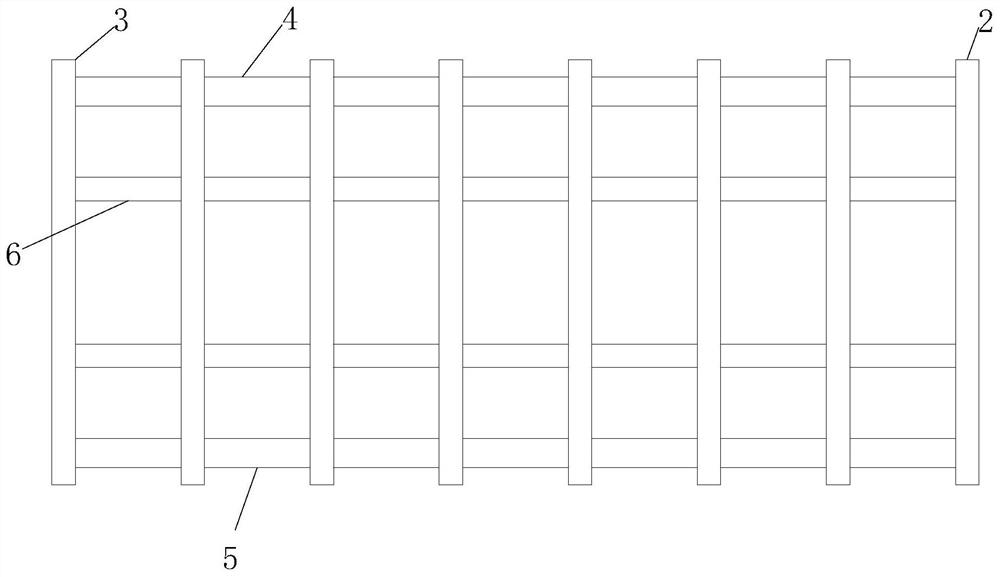

[0018] Refer figure 1 , figure 2 The present invention proposes a steaming furnace of a steam aerated concrete sheet, including a furnace body 1, a force, a drive, and an alifter; in which:

[0019] The furnace body 1 is provided with a feed port and a furnace cover is mounted at a feed opening. The mover is disposed in the furnace body 1 and is mounted on the furnace body 1 through the rotating shaft, and the mounting port is provided in the interior of the transfer station and the mount is adjacent to the feed port. The artifer is inserted into the mount inside the mounting port, the artifact is connected to the mount and can be rotated as the transfer; the driver is connected to the force and drive the transfer frame.

[0020] The present invention is rotated by a driving member drive, which rotates, thereby rotating the sheet metal inside the artifact, can make the sheet to high temperature high pressure water vapor, steaming is more uniform, avoiding appearing The steaming un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com