Battery production discharging device

A battery and corresponding position technology, applied in sorting and other directions, can solve the problems of increasing the difficulty of detection and achieve the effect of reducing the difficulty of detection and avoiding crashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

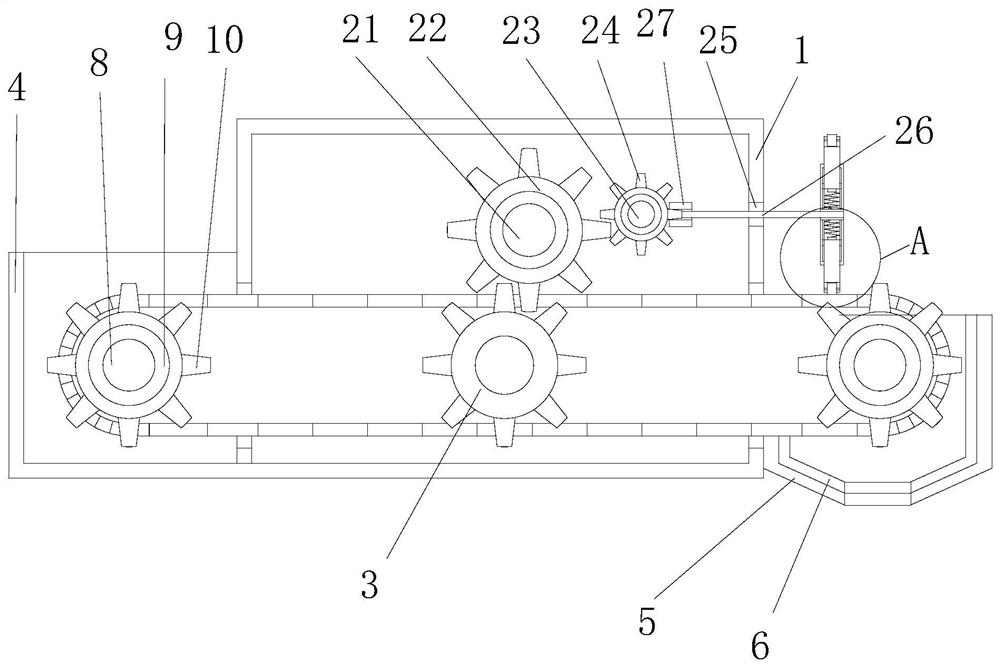

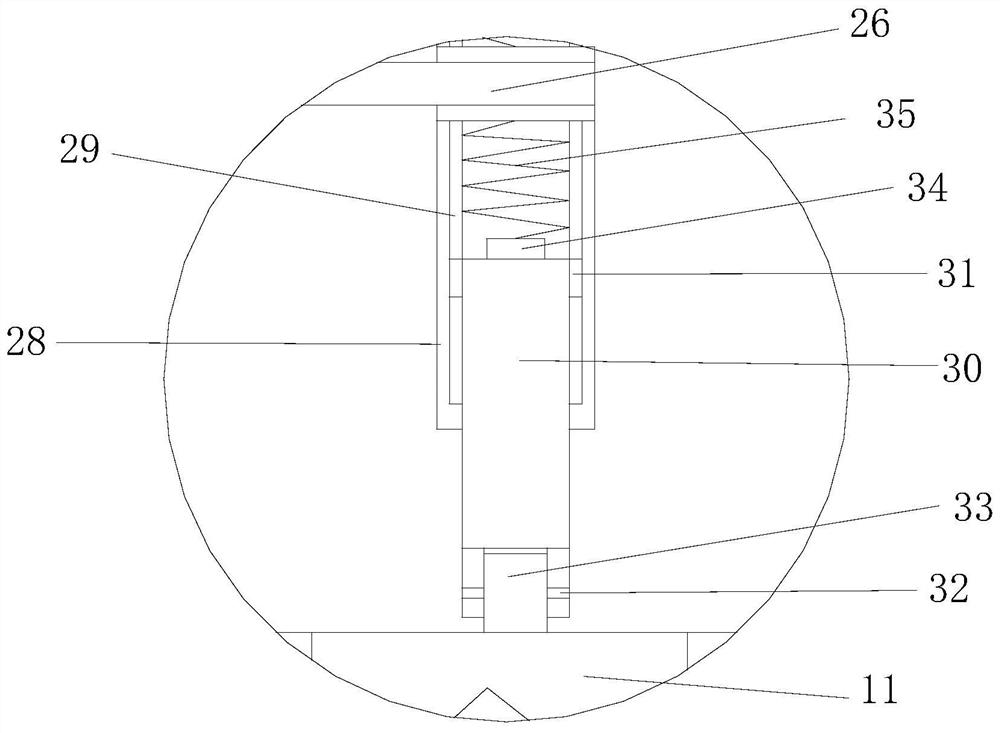

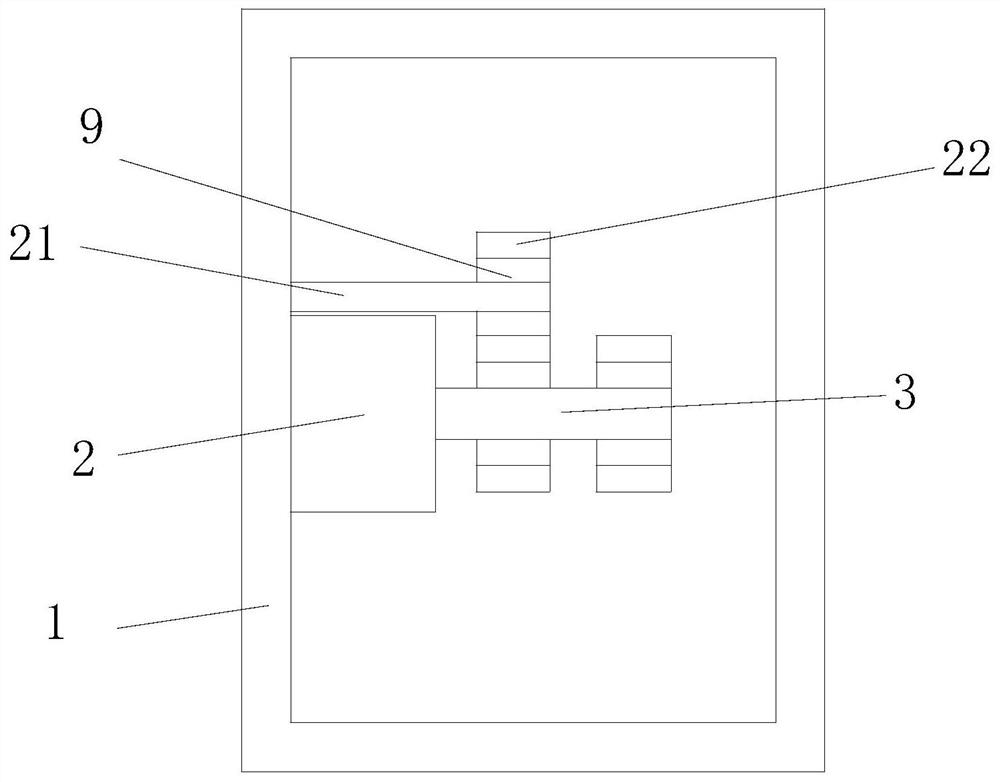

[0028] Example: such as Figure 1-Figure 7 As shown, a discharge device for battery production includes an outer frame 1, the outer frame 1 is in the shape of a hollow rectangle, rectangular holes are opened on the left and right sides of the outer frame 1 near the bottom, and the inner front side wall of the outer frame 1 is fixed A motor 2 is installed, and a first gear 3 is fixedly installed on the output shaft of the motor 2. The first gear 3 is composed of two sets of gears and a set of cylinders, wherein the wall surface of the corresponding position of the hole on the gear near the front side of the first gear 3 is the same as that of the first gear. The side wall of the output shaft on the motor 2 is fixedly connected, wherein the side wall of the two groups of gears on the first gear 3 is fixedly connected with the front and rear sides of the column on the first gear 3, and the left side of the outer frame 1 is fixedly installed with a stopper. Plate 4, the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com