Water cup pressing and assembling device

A technology for assembling equipment and water cups, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., and can solve the problems of messy placement of water cups, low efficiency of manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

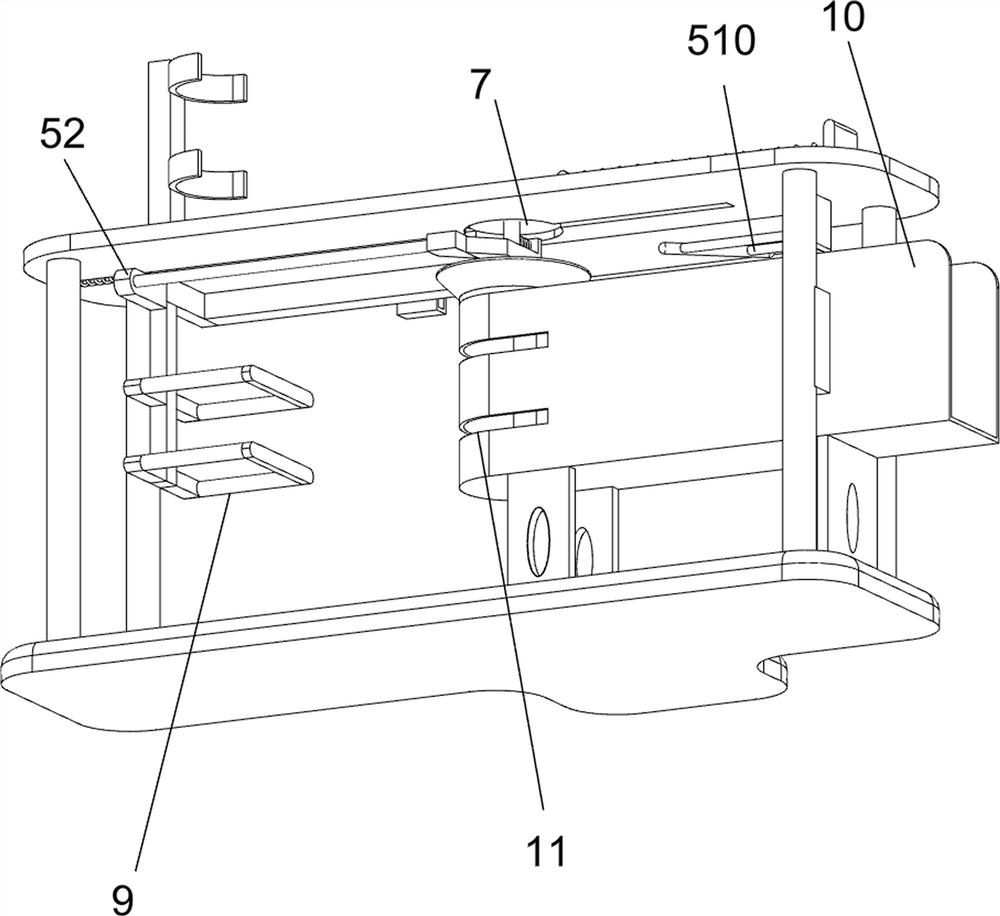

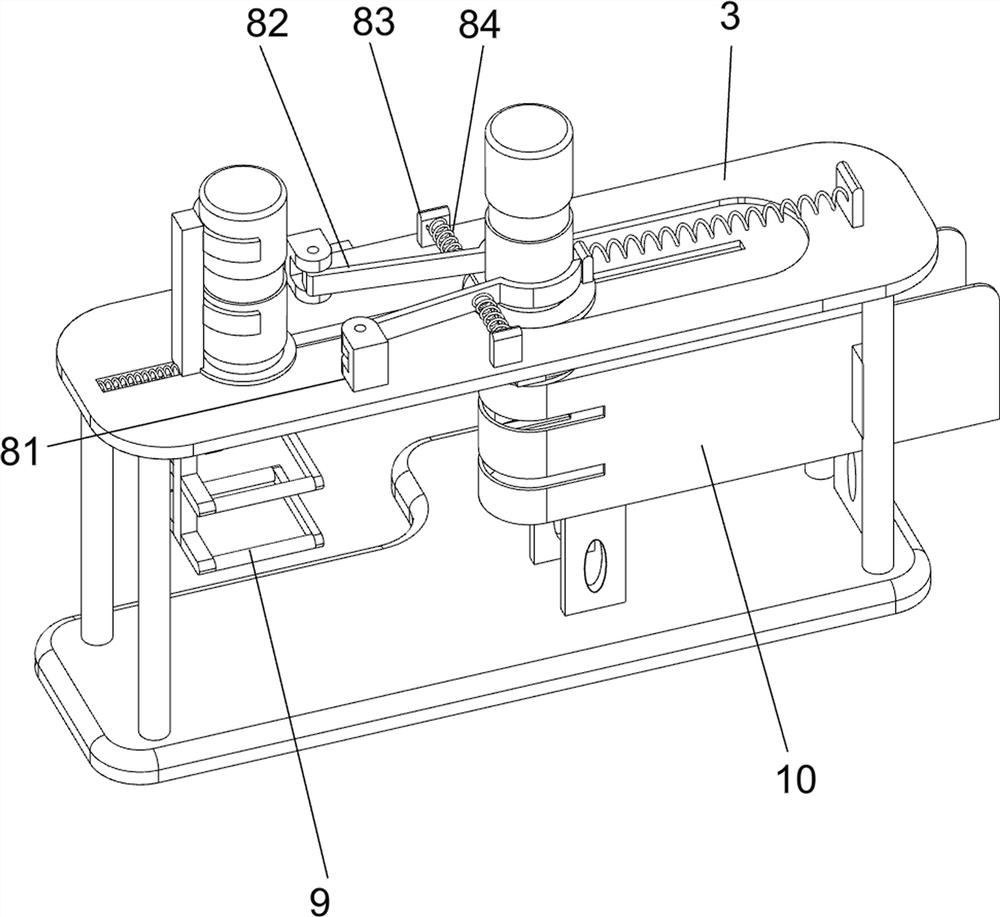

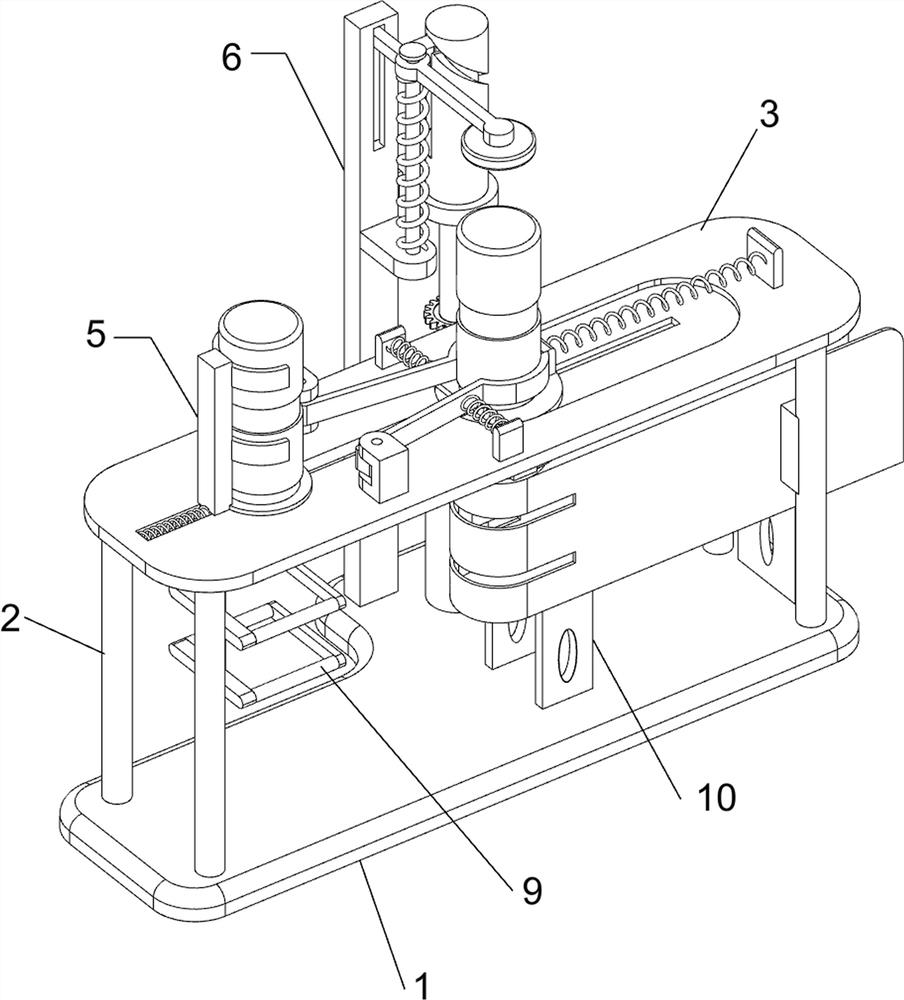

[0025] A water cup press assembly equipment, such as Figure 1-8 As shown, it includes a base 1, a supporting column 2, a supporting plate 3, an electric push rod 4, a pushing mechanism 5, a pressing mechanism 6 and a clamping assembly 8. The left and right sides of the top of the base 1 are symmetrically provided with supporting columns 2, and one side is supported The number of columns 2 is two, and a support plate 3 is arranged between the tops of the support columns 2 on both sides; The side is connected with the electric push rod 4, and the middle of the top rear side of the base 1 is provided with a pressing mechanism 6, and one side of the pressing mechanism 6 is connected with the electric push rod 4. Located below the pressing position, the top of the support plate 3 is provided with a clamping assembly 8 on the left side, and the clamping assembly 8 is located on both sides of the pushing mechanism 5 .

[0026] The pushing mechanism 5 includes a sliding frame 52, a ...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 and Figure 7-8 As shown, it also includes a push frame 9 and a collection frame 10, the bottom of the slide frame 52 is provided with the push frame 9, the top right side of the base 1 is provided with the collection frame 10, and the left side of the collection frame 10 has an opening 11.

[0035] In order to facilitate the user to collect the assembled water cup, the assembled water cup will drop from the circular through hole 7 into the collection frame 10. When the sliding frame 52 drives the assembled water cup to move to the right, the sliding frame 52 will also drive The push frame 9 moves to the right, and the push frame 9 moves to the right through the opening 11 to push the water cup in the collection frame 10 to move to the right, which is convenient for the next assembled water cup to fall. Hold the assembled drinking glass sideways.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com