Field prefabricated wallboard mounting structure

A technology of prefabricated wall panels and installation structures, applied in building structure, building materials, construction, etc., can solve problems such as difficult construction, complicated process, and large hidden danger of water leakage, and achieve the effect of reliable structural safety and accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

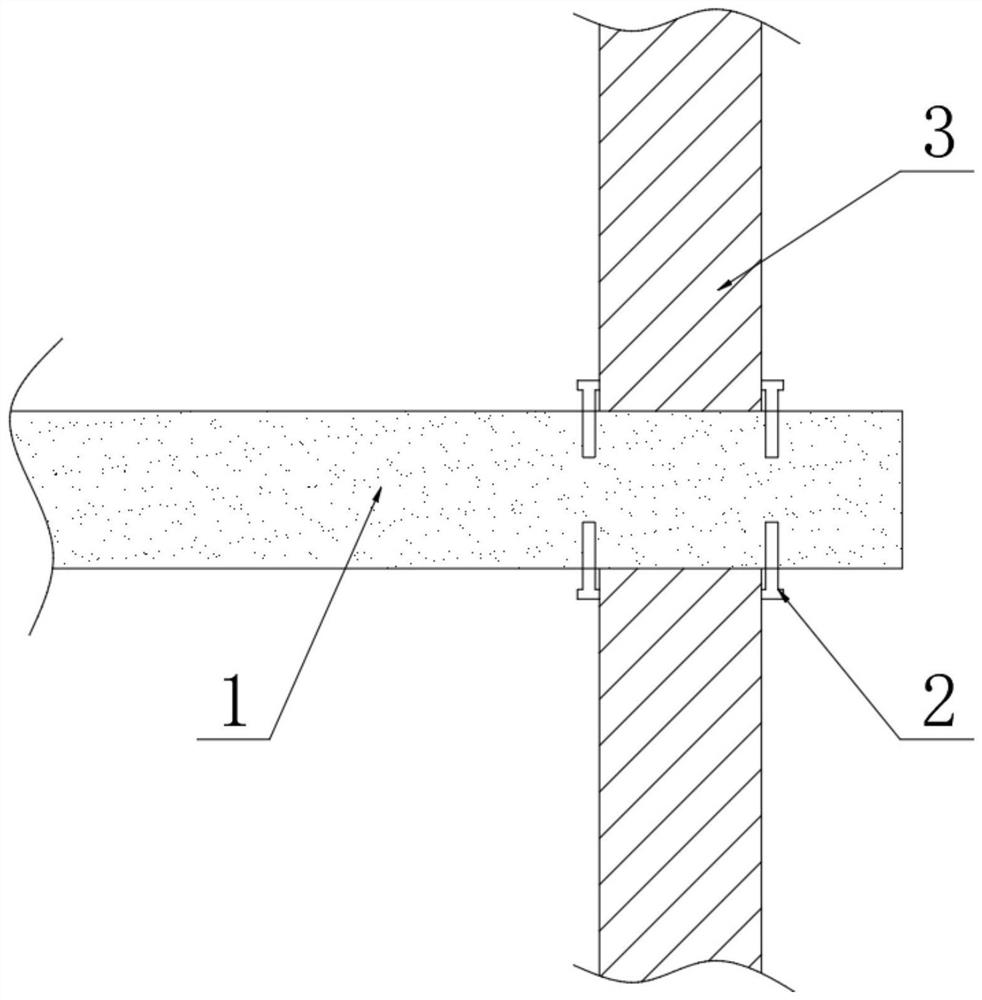

[0018] like figure 1 As shown, the present invention relates to an on-site prefabricated wall panel installation structure, which includes a concrete board 1, and the upper and lower sides of the concrete board 1 are provided with two rows of anchor bolts 2 on the left and right, and the two rows of anchor bolts 2 on the left and right are clamped There are prefabricated wall panels 3, and the outer covering of two rows of anchor bolts 2 on the left and right is provided with a post-cast surface layer or a plastering layer;

[0019] The height of the anchor bolt 2 exposed to the concrete slab 1 is 20 mm.

[0020] In addition to the above-mentioned embodiments, the present invention also includes other implementations, and any technical solution formed by equivalent transformation or equivalent replacement shall fall within the protection scop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com