A pretreatment method for volcanic rock type uranium ore with high acid consumption and difficult to leach

A technology for volcanic rock and uranium ore, which is applied in the field of pretreatment of volcanic rock type uranium ore, can solve the problems of large reagent consumption, large proportion of titanium-uranium ore, and low uranium leaching rate, so as to reduce reagent consumption, increase leaching rate, and reduce development costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A titanium-containing uranium ore is a volcanic rock-type uranium ore, and the ore is mainly composed of muscovite, quartz, calcite, epidote, rutile, fluorite, apatite, zircon, pitchblende, titanium uranite, pyrite, rutile , sphalerite, ilmenite, colloidal molybdenite, galena, magnetite, uranite, etc. Uranium mainly exists in the form of independent uranium minerals, including uranite, pitchblende, uranite, and a small amount of The isomorphic form exists in uranium thorium stone. The grade of uranium in the ore is 0.31%.

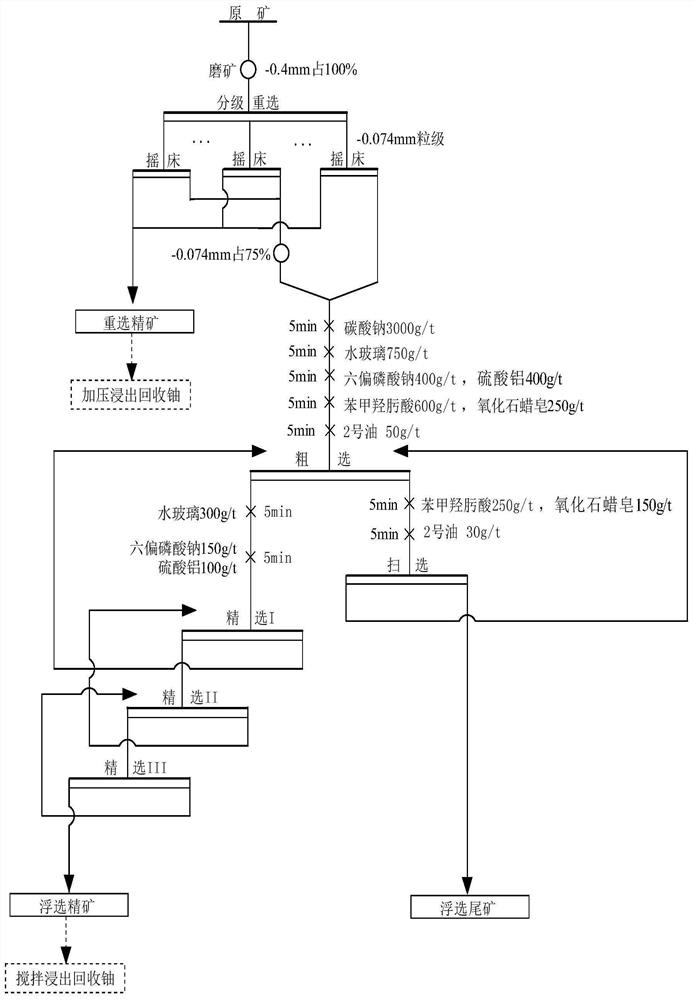

[0039] (1) Crush the ore particle size to -8mm, grind the ore to a fineness of -0.6mm, and then divide it into -0.6mm~+0.3mm, -0.3mm~+0.15mm, -0.15mm~+0.074mm, -0.074mm four groups.

[0040] (2) The ores of each particle size of the group are re-selected with a shaking table respectively, and the gravity-selected concentrates of each particle size are combined to obtain a shaking table gravity-selected concentrate, most of the titanium-uranium ore ...

example 1

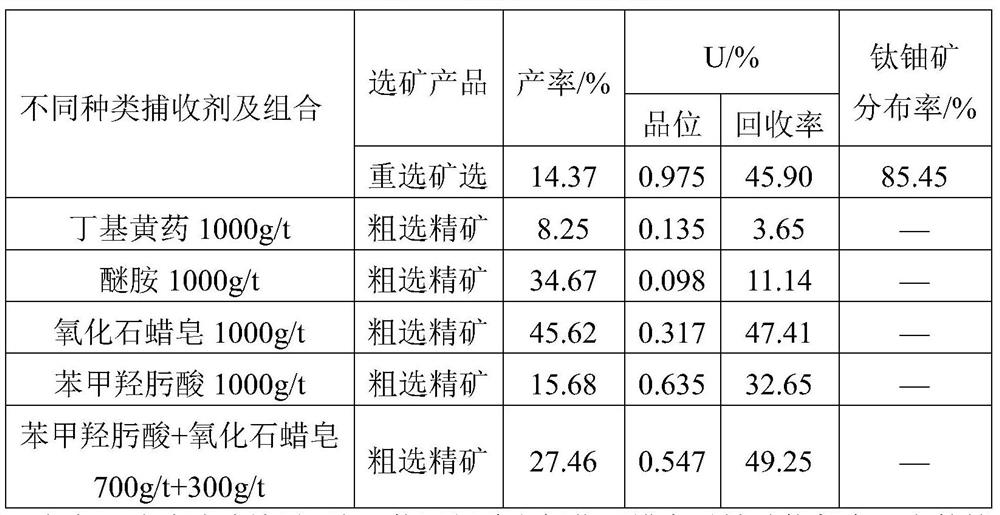

[0044] Example 1 test results are shown in Table 1.

[0045] Table 1 Example 1 test results

[0046]

[0047] It can be seen from the test results in Table 1 that both benzoic acid and oxidized paraffin soap have a certain collection capacity for uranium minerals. However, when oxidized paraffin wax soap is used alone, the yield of roughing concentrate is high and the grade of uranium is low; when benzhydroxamic acid is used alone, the selectivity to uranium minerals is better, and the grade of roughing concentrate is higher, but the grade of benzhydroxamic acid is higher. The acid collection ability is weak, and the recovery rate of uranium is low; when benzohydroxamic acid and oxidized paraffin soap are used together, the two agents can have a synergistic collection effect, and high-grade and high-recovery roughing concentrates can be obtained .

Embodiment 2

[0049] A titanium-containing uranium ore is a volcanic rock-type uranium ore, and the ore is mainly composed of muscovite, quartz, calcite, epidote, rutile, fluorite, apatite, zircon, pitchblende, titanium uranite, pyrite, Composed of rutile, sphalerite, ilmenite, colloidal molybdenite, galena, magnetite, uranite, etc. Uranium mainly exists in the form of independent uranium minerals, including uranite, pitchblende, uranite, and a small amount It exists in uranium thorium stone in the form of isomorphism. The grade of uranium in the ore is 0.31%.

[0050] (1) Crush the ore particle size to -5mm, grind the ore to a fineness of -0.3mm, and then divide it into three groups -0.3mm~+0.15mm, -0.15mm~+0.074mm, and -0.074mm according to the ore particle size.

[0051] (2) The ores of each particle size of the group are re-selected with a shaking table respectively, and the gravity-selected concentrates of each particle size are combined to obtain a shaking table gravity-selected conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com