A convenient and fast nailing device for plates

A convenient and fast technology, applied in the direction of nailing tools, staple nailing tools, manufacturing tools, etc., it can solve the problems of not being able to nail large plates, and not being able to store multiple nails, so as to improve work efficiency and prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

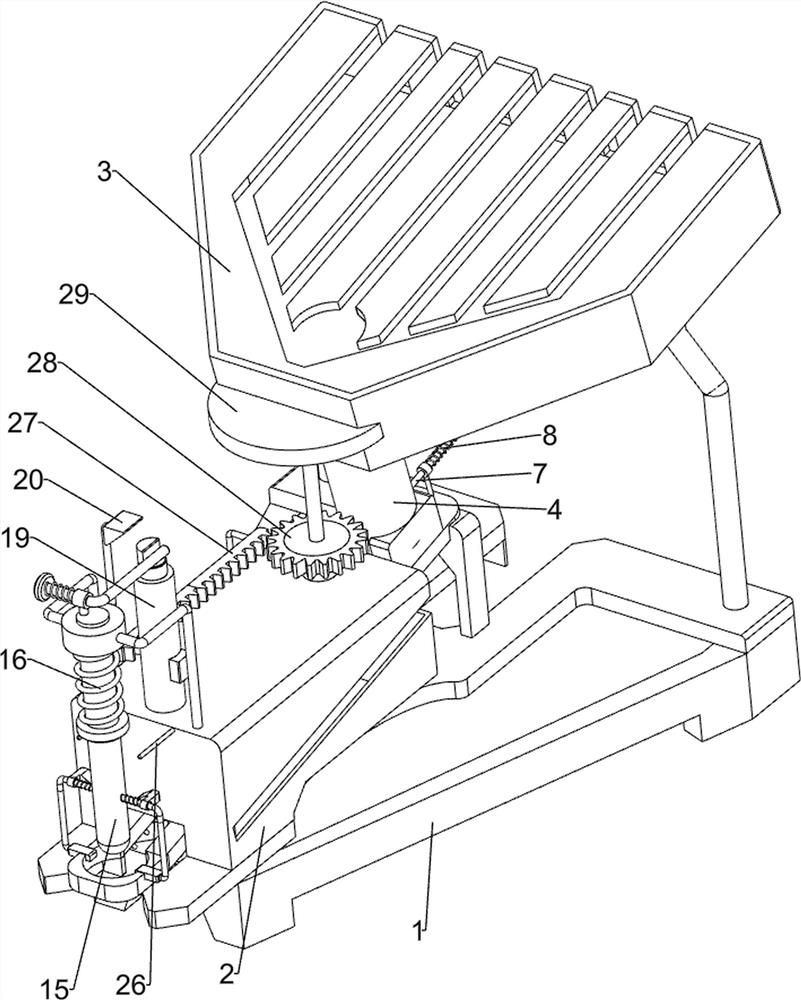

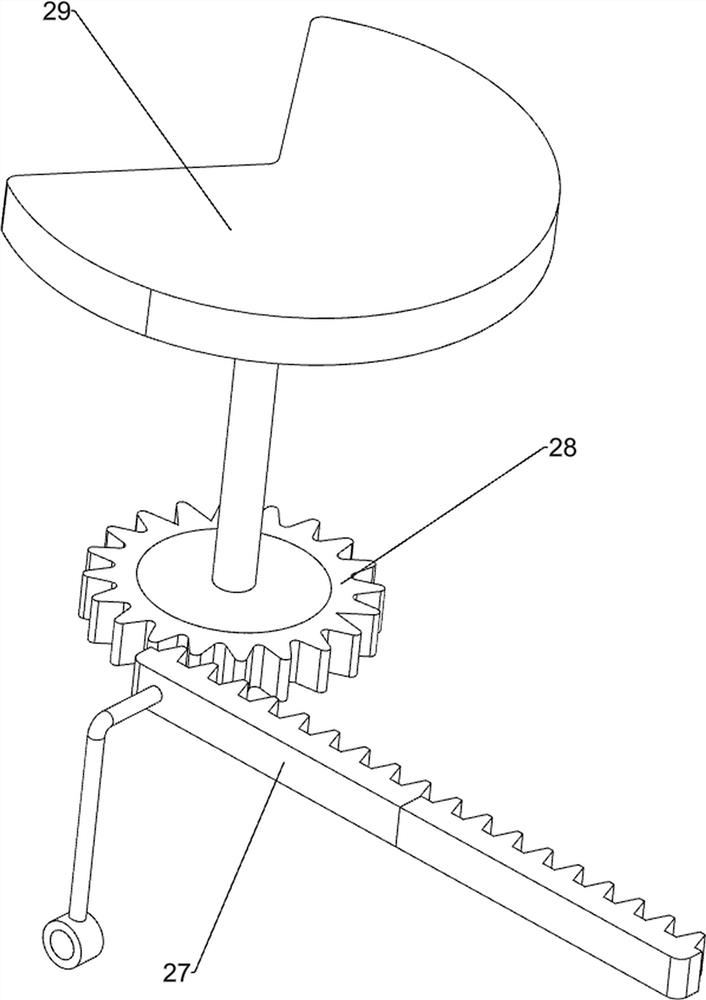

[0022] A convenient and fast nailing device for plates, such as Figure 1-Figure 5 As shown, it includes a frame 1, an installation frame 2, a blanking assembly, a pushing assembly and a nailing assembly. The frame 1 is used to install the entire device, and the right part of the frame 1 is fixed with the installation frame 2 by screws. 1. On the left side of the top, there is a blanking assembly for unloading by sliding. In the middle of frame 1, there is a pushing assembly for pushing. The pushing assembly cooperates with the unloading assembly. There are nailing units that are driven by a push method.

[0023] When it is necessary to nail the plate, the staff first moves the plate under the nailing assembly, then puts a certain amount of nails into the blanking assembly, and then starts the nailing assembly to work. A certain amount of nails in the blanking assembly When the nail slides into the pusher assembly, push the nail to the nailing assembly through the pusher asse...

Embodiment 2

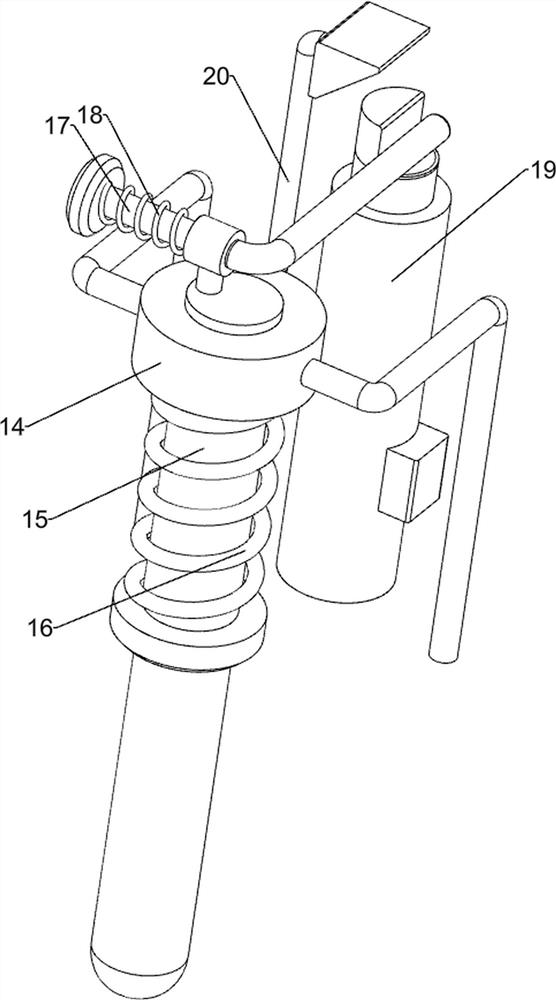

[0031] On the basis of Example 1, such as figure 1 , image 3 and Figure 5 Shown, also comprise special-shaped bar 21, the 5th spring 22, pull plate 24, the second wedge-shaped block 25 and the second contact bar 26, special-shaped bar 21 is two, beat bar 15 bottom slides and be provided with special-shaped bar 21, The fifth spring 22 is connected between the special-shaped rod 21 and the hammer rod 15, the top right side of the guide rail 10 has a groove 23, and the bottom of the special-shaped rod 21 is fixed with a pull plate 24 by screws, and the pull plate 24 cooperates with the groove 23 , special-shaped bar 21 tops are all provided with the second wedge-shaped block 25, and the second contact rod 26 is two, and the right side of mounting frame 2 is welded with the second contact rod 26, and the second contact rod 26 cooperates with the second wedge-shaped block 25.

[0032]When hammering bar 15 to slide upwards, drive special-shaped bar 21 to move upwards, and then d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com