Automatic nailing machine for packaging box production and control method thereof

A packaging box, automatic technology, applied in the direction of packaging, transportation and packaging, box making operations, etc., can solve the problems of hearing damage, uneven inner support, manual operation fatigue, etc., to improve the level of automation, accurate nailing position, nailing fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

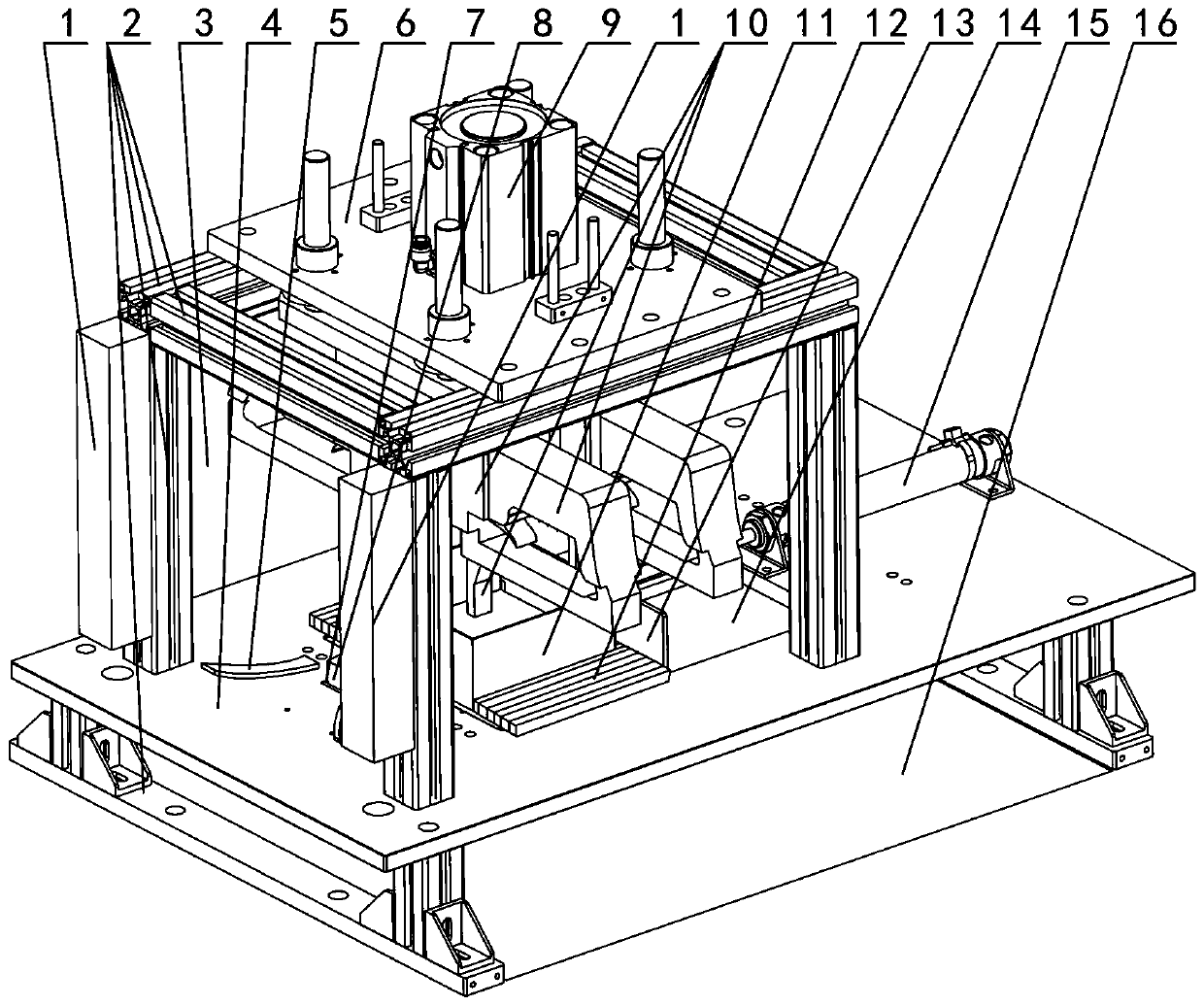

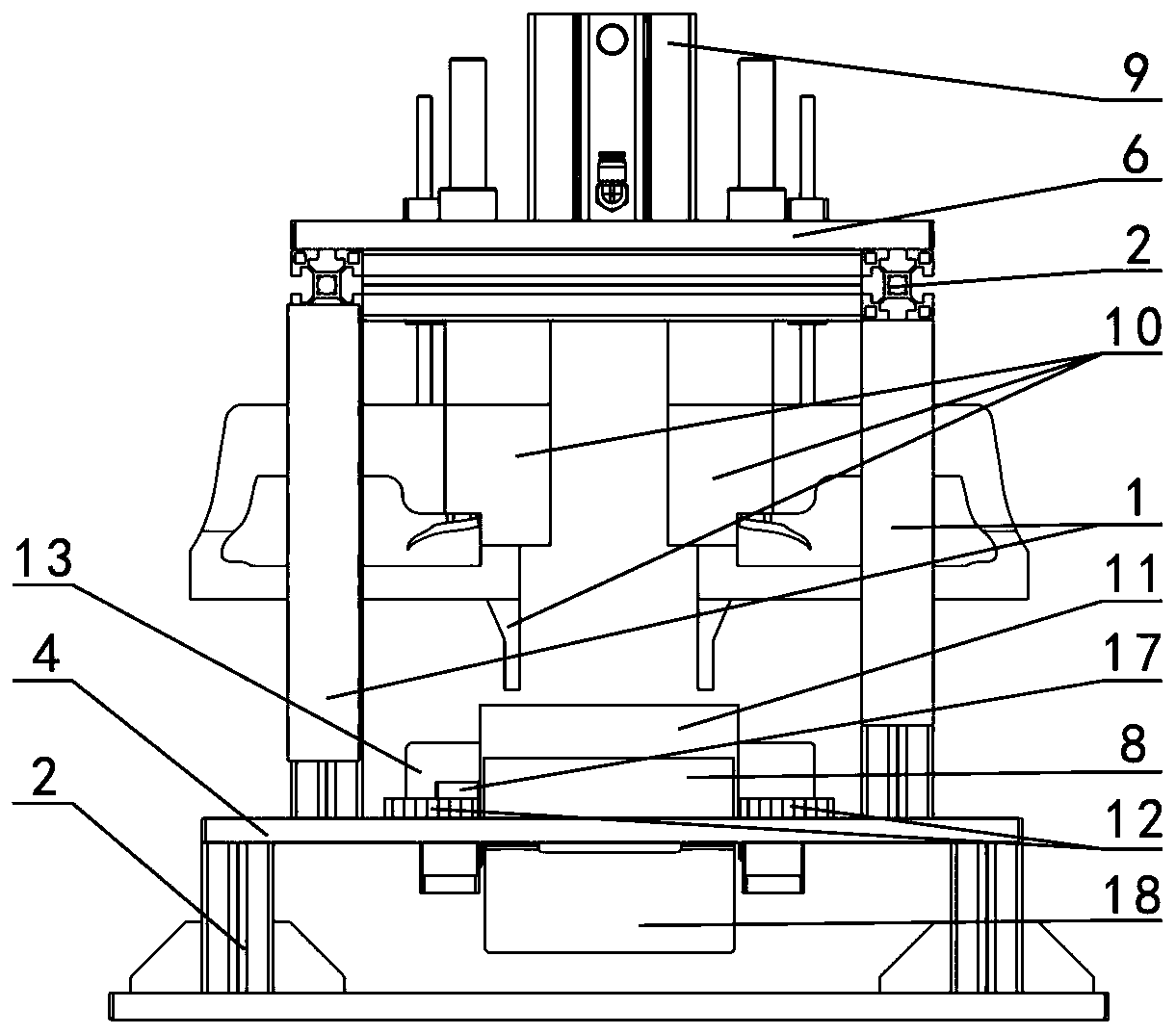

[0031] Such as figure 1 and figure 2 As shown, the automatic nailing machine for packaging box production according to the present invention is used for nailing the piece to be nailed (in the present invention, the inner box 11 with a base in the figure), including a frame 2, a safety grating 1, a nailing Nail cylinder 9, nail gun 10, push plate cylinder 15, push plate 13, jacking cylinder 18, push material cylinder 8, proximity sensor 17 and controller (not shown in the figure, generally placed in the electric control box, the electric control box It is generally installed on the frame for easy operation), the bottom of the frame 2 is provided with a conveyor belt 16 for transmitting nailed parts, the running direction on the conveyor belt 16 is set to run forward from the rear, and the frame 2 is provided with a horizontal conveyor belt 16. The operation base plate 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com