Smoke box capable of detecting smoke-sensing fire detectors in batches and using method thereof

A technology for smoke detection and batch detection, which is applied in measuring devices, scientific instruments, suspensions and porous material analysis, etc. It can solve the problems of low detection efficiency, reduce detection costs, facilitate pick and place, and improve detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

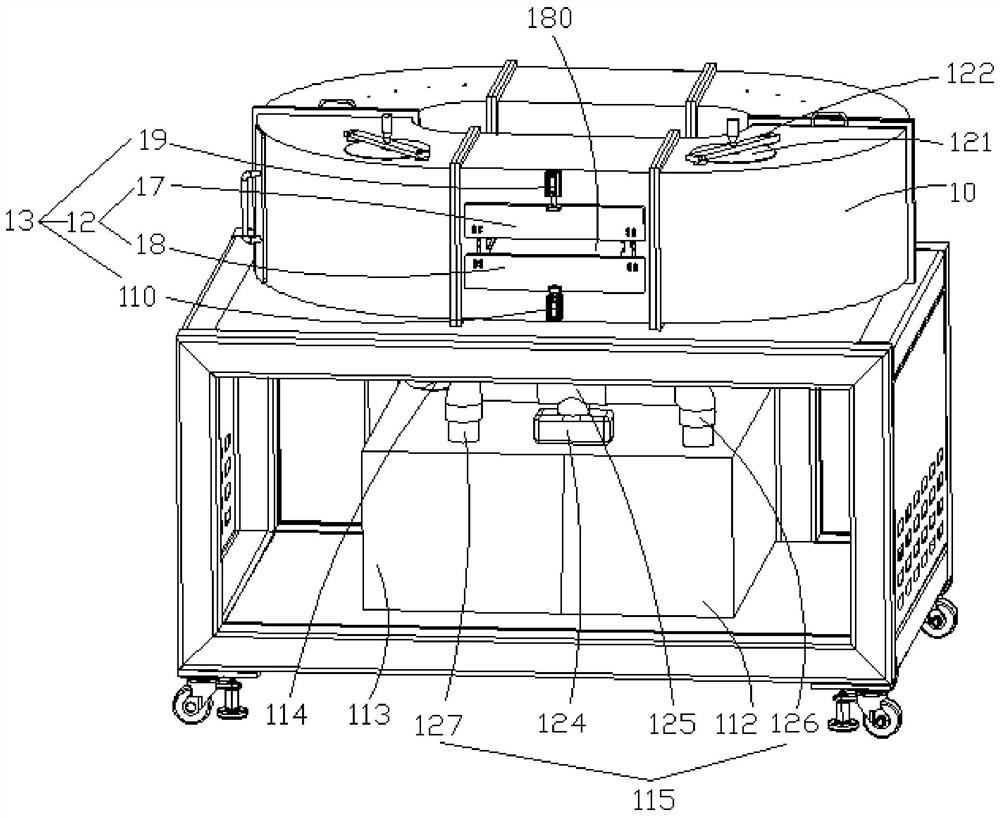

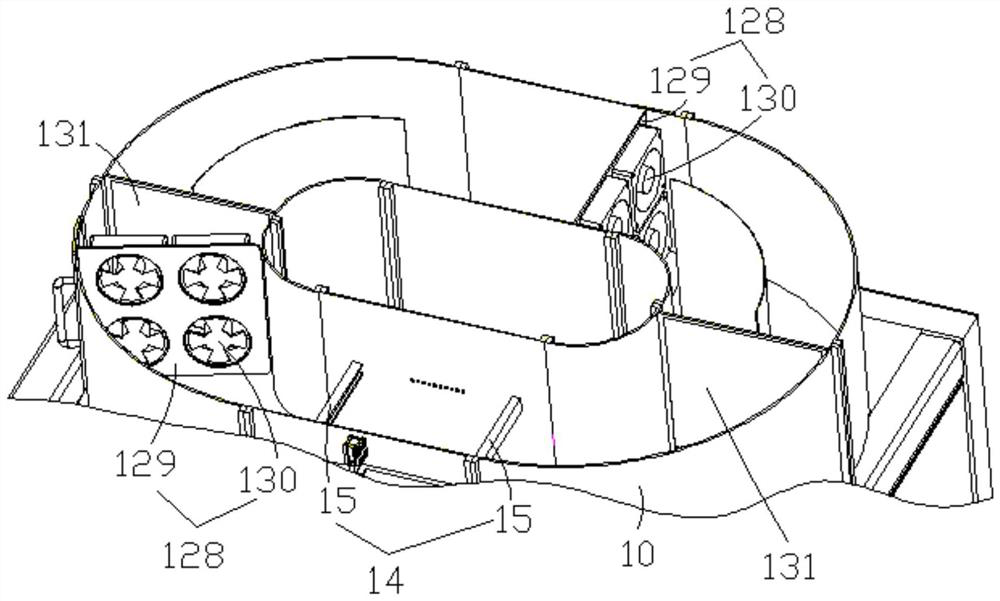

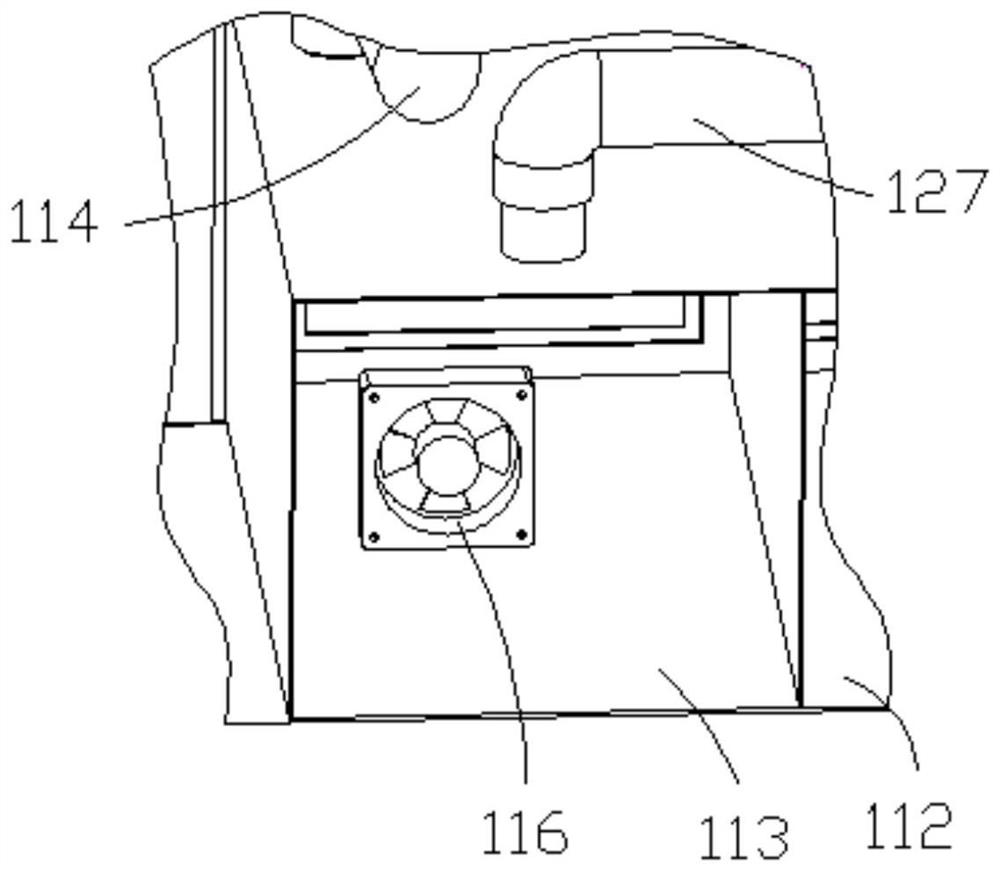

[0019] The embodiment of the present invention provides a smoke box that can detect smoke detectors in batches, such as Figure 1-Figure 5 As shown, it includes a smoke box flue 10; the smoke box also includes a transverse movable plate 11; the upper surface of the movable plate 11 is provided with multiple sets of anti-off components; along the flow direction of the smoke, any set of anti-off components are not blocked The remaining anti-detachment components are covered; the anti-detachment components correspond to the tested smoke fire detectors one by one, and are used to prevent the tested smoke fire detectors from detaching from the movable plate 11 during detection; the outer surface of the smoke box flue 10 is set There is a first opening 180 for the movable plate 11 to enter or exit; the smoke box also includes a first sealing plate 12 that blocks the first opening 180 during detection, and a driving assembly 13 that drives the first sealing plate 12 to approach or mov...

Embodiment 2

[0030] An embodiment of the present invention provides a method for using a smoke box. Based on the smoke box provided in Embodiment 1 that can detect smoke detectors in batches, the method includes the following steps:

[0031] Step S1: Before testing, four smoke detectors to be tested are respectively installed on the movable plate through four sets of anti-loosening components, and the driving component drives the first sealing plate away from the first opening.

[0032] Step S2: Put the movable plate with the four smoke detectors to be tested into the first opening, and under the guidance of the guide assembly, push the movable plate completely into the flue of the smoke box.

[0033] Step S3: After the movable plate completely enters the flue of the smoke box, the driving component drives the first sealing plate close to the first opening until the first opening is completely blocked, and then the detection work can be started.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com