Welding Control Device For Welding Tool And Method of Force Adjustment To Welding Tool

A technology for welding tools and control devices, which can be used in manufacturing tools, welding equipment, resistance welding equipment, etc., and can solve problems such as unusable components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

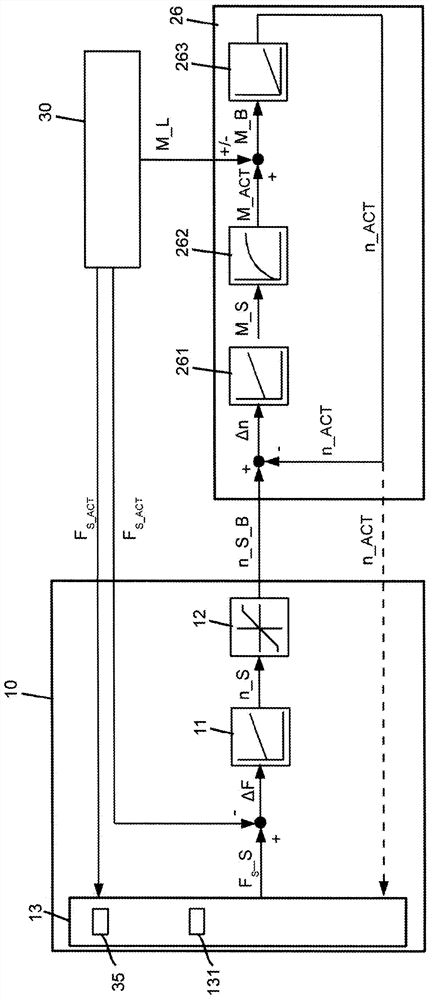

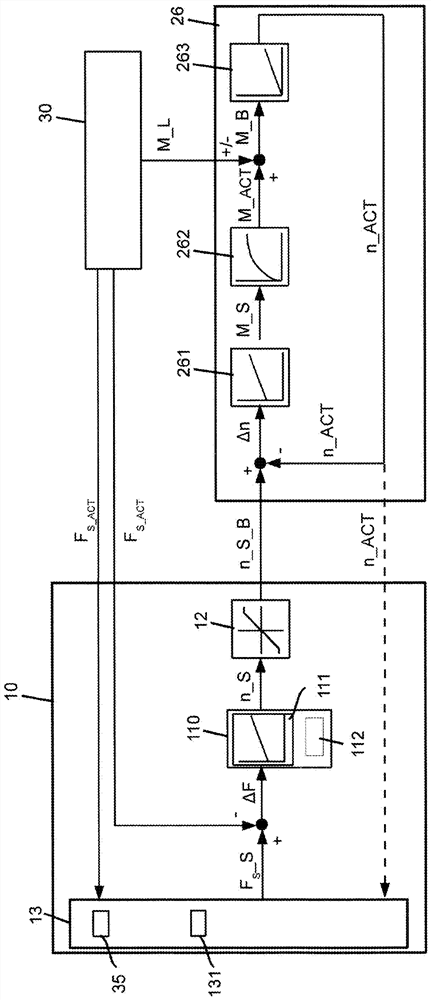

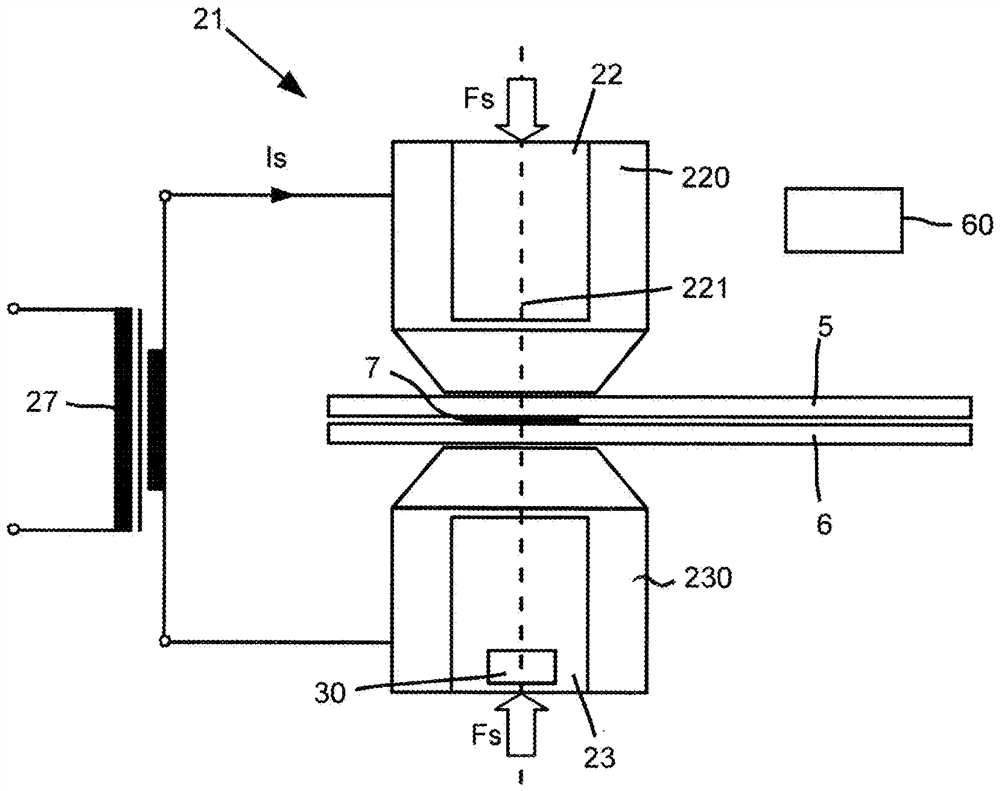

[0033]figure 1 An industrial system 1 is shown with a welding system 2 which is used to weld at least one metal component 5,6. In this case, at least one metal member 5, 6 is connected to at least one welding connection 7. The at least one welding connection 7 is, for example, a welding point and / or a weld seam. In this case, the two metal members 5, 6 are connected to each other, or only two edges of one of the members 5, 6 are also connected to each other.

[0034]The industrial system 1 is, for example, a production line for vehicles, furniture, buildings, etc., in which metal members 5, 6 are welded. To this end, the welding system 2 has a welding control device 10, a device 20 for guiding a welding tool 21, a detection device 30 and an operating device 40, which is implemented as a resistance welding tool and has two welding electrodes 22, 23. The equipment 20 is controlled by the control device 25. Furthermore, communication lines 41 to 45 are provided, and these communication li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com