Automatic take-up type ink box

A linear and automatic technology, applied in the direction of conveying filamentous materials, workshop equipment, manufacturing tools, etc., can solve the problem that the ink fountain cannot be automatically retracted, and achieve the effect of simple, fast and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

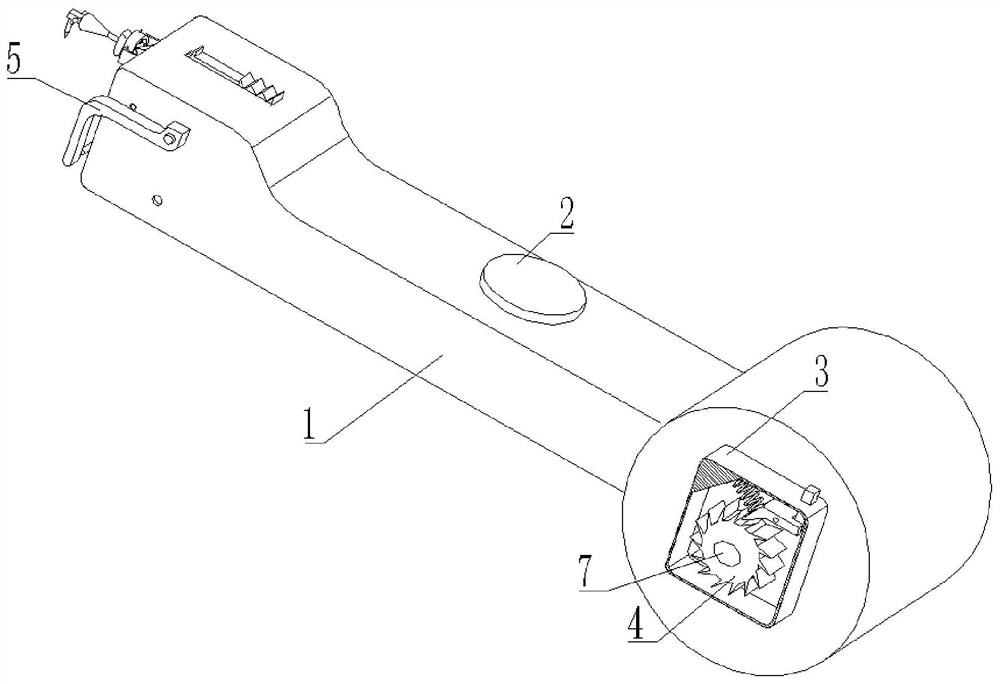

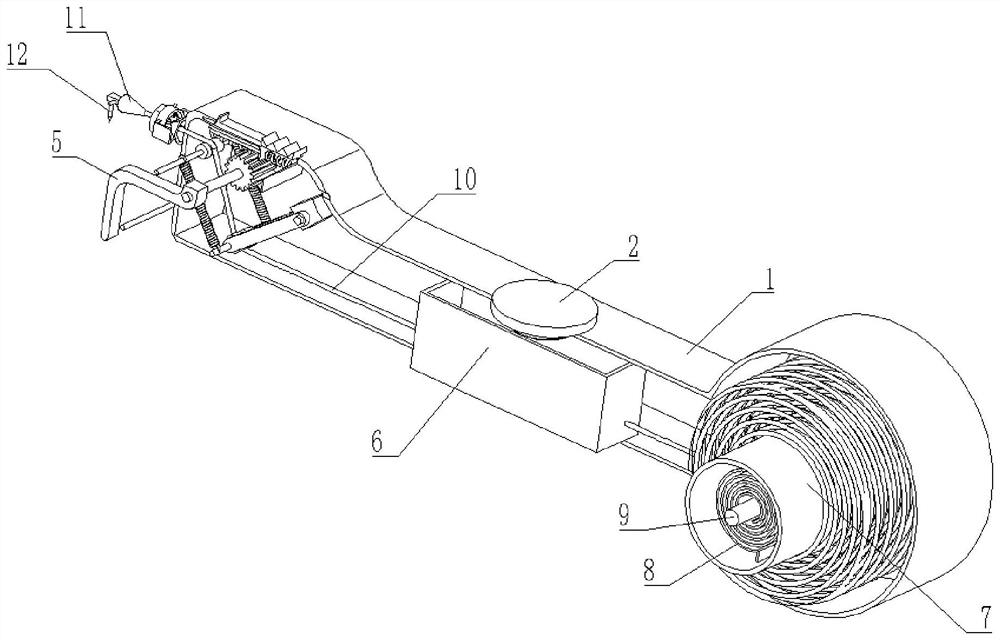

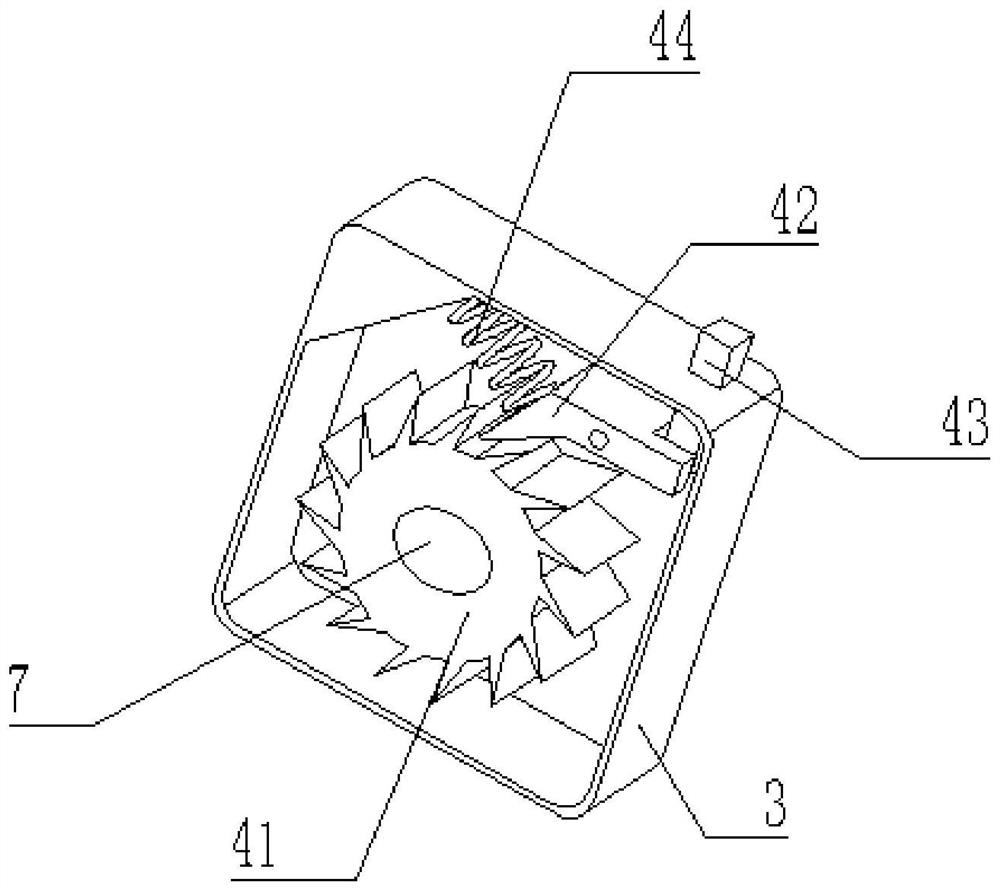

[0033] see Figure 1-5 , an automatic take-up type ink cartridge, comprising a box body 1, the upper surface of the box body 1 is threadedly connected with a threaded cover 2, the inside of the box body 1 is connected with an ink tank 6 by bolts, and the inner wall of the box body 1 is connected with a rotary The sleeve 7, the inner wall of the box body 1 is fixedly connected with the reel 9, the reel 9 is located inside the rotary sleeve 7, a coil spring 8 is arranged between the rotary sleeve 7 and the reel 9, and one end of the coil spring 8 is fixedly connected with the inner wall of the rotary sleeve 7 , the other end of coil spring 8 is fixedly connected with the surface of reel 9, and the left side of box body 1 is provided with control mechanism 5, and the front portion of box body 1 is welded with side box 3, and the inside of side box 3 is provided with fixing mechanism 4.

[0034] Further, the surface of the rotary sleeve 7 is wound with an ink thread 10, one end of...

Embodiment 2

[0040] see Figure 6-Figure 7 , the cleaning device 505 includes a cleaning sleeve 5051, the surface of the cleaning sleeve 5051 is fixedly connected with a support plate 5054, the surface of the support plate 5054 is fixedly connected with a sliding pole 5055, and the surface of the sliding pole 5055 is slidingly connected with a circular sleeve 5052, and the circular sleeve The surface of 5052 is fixedly connected with connecting plate 5053, and the right side of connecting plate 5053 is fixedly connected with the left side of box body 1.

[0041] Further, there are three cleaning sleeves 5051, and the three cleaning sleeves 5051 are distributed in a circular array with the center of the circle sleeve 5052 as the axis of symmetry. The effect is to press the three cleaning sleeves 5051 tightly on the ink line 10, so that the diameter of the three cleaning sleeves 5051 can be enlarged or reduced, and the cleaning of the ink line 10 can be better cleaned. The effect is the bes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com