A reactor double-plate equal flow flow distribution device and flow distribution structure

A flow distribution device and flow distribution technology, applied in the field of nuclear power, can solve problems such as uneven flow distribution, achieve the effects of easy replacement and maintenance, compact and simple structure, and ease eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

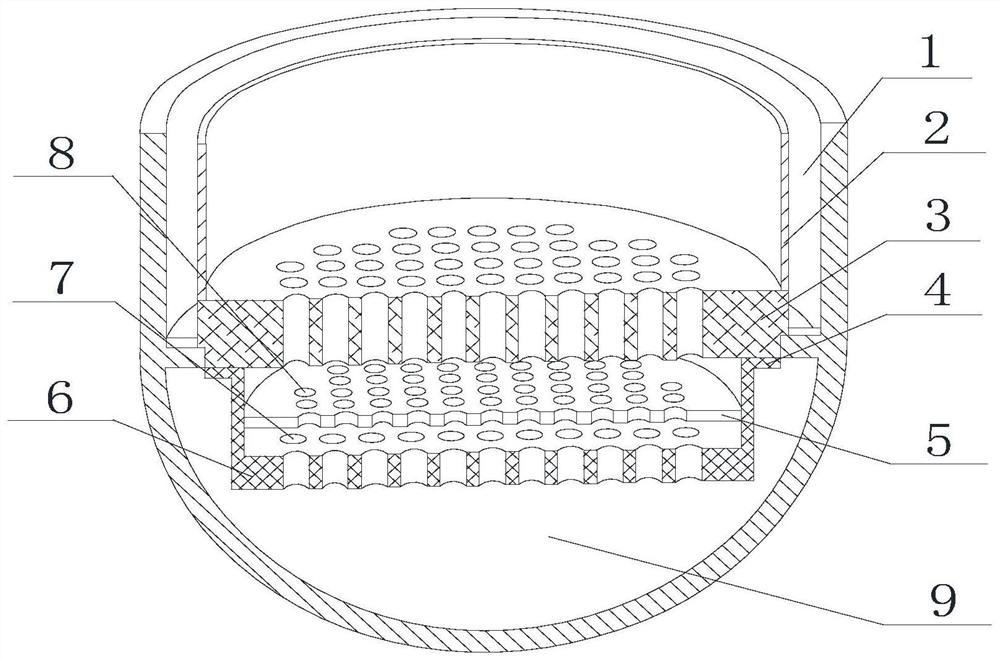

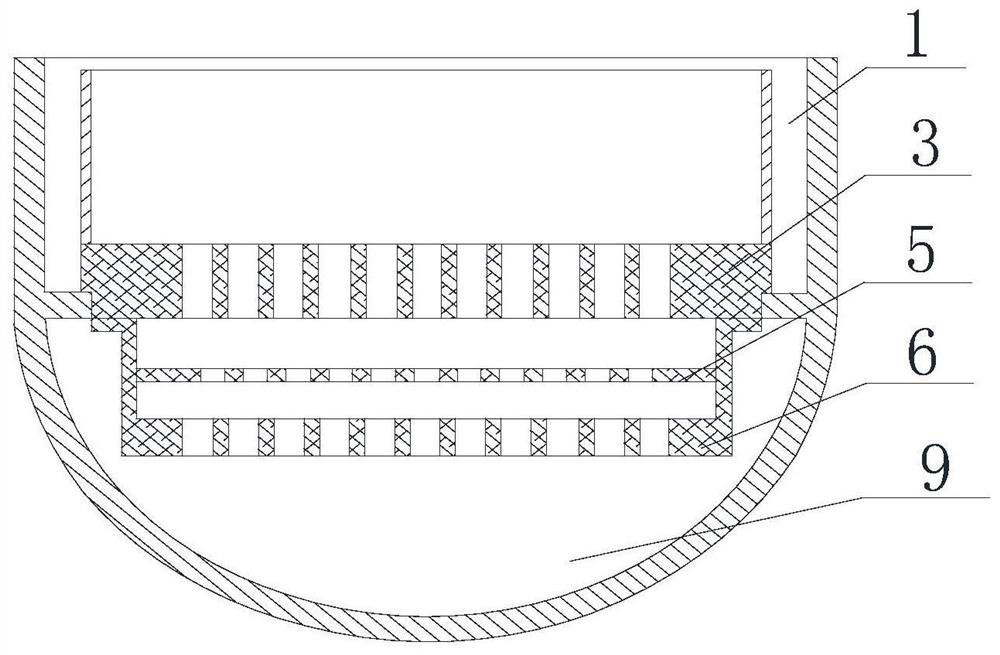

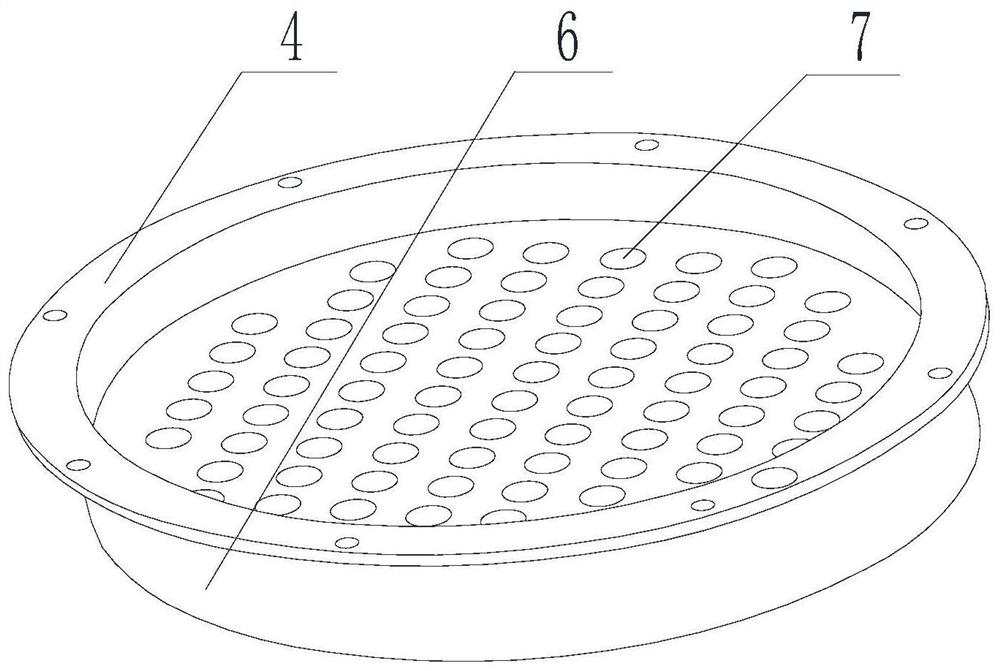

[0046] like Figure 1-Figure 4 As shown, a reactor double-plate equal-flow flow distribution device includes a pressure vessel, a hanging basket 2 and a support plate 3 under the core, the hanging basket 2 is arranged in the pressure vessel, and the outer wall of the hanging basket 2 is connected to the pressure vessel An annular descending chamber 1 is formed between the inner walls. The core lower support plate 3 is arranged at the bottom of the hanging basket 2. The bottom of the pressure vessel forms a lower chamber 9 below the core lower support plate 3. The core The lower support plate 3 is provided with a number of through holes, and also includes a secondary flow equalizer 5 and a flow distribution cylinder 6, the flow distribution cylinder 6 is installed in the lower chamber 9, one end of the flow distribution cylinder 6 is an open end, and the other end It is a closed end, and the beginning of the flow distribution cylinder 6 is connected to the bottom of the lower s...

Embodiment 2

[0050] like Figure 1-Figure 4 As shown, this embodiment is based on Embodiment 1, and the aperture of the second flow hole 8 is 1 / 3 to 1 / 2 of the aperture of the first flow hole 7; the number of first flow holes on the flow distribution cylinder 6 7 have the same aperture; the apertures of several second flow holes 8 on the secondary equalizer plate 5 are the same; several first flow holes 7 are evenly distributed on the flow distribution cylinder 6, and some second flow holes 8 Evenly distributed on the flow plate 5.

Embodiment 3

[0052] like Figure 1-Figure 4 As shown, this embodiment is based on Embodiment 1, the distance between the bottom of the flow distribution cylinder 6 and the bottom of the lower chamber 9 is consistent with the height of the flow distribution cylinder 6; the secondary flow equalizer 5 and the core lower support plate 3 The distance between them is 1 / 2 of the height of the flow distribution cylinder 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com