An automatic winding device for pre-twisted wires of transmission lines

A technology of transmission lines and winding devices, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of reduced service life of transmission lines, high labor intensity, unsuitable for one-handed operation, etc., and achieve the effect of improving stability and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

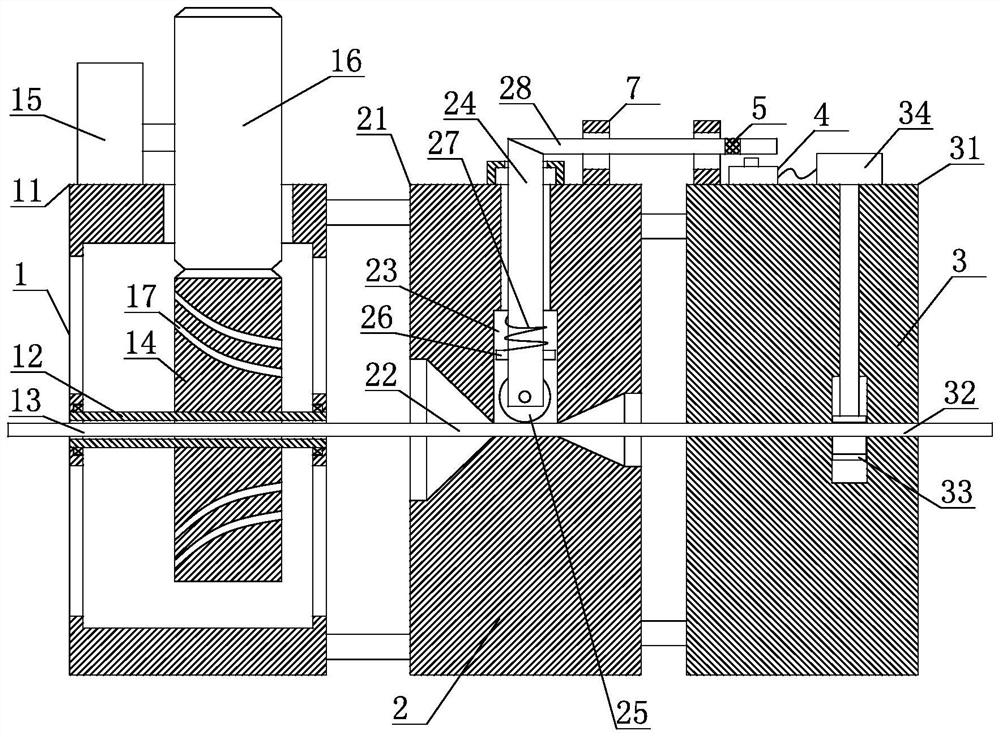

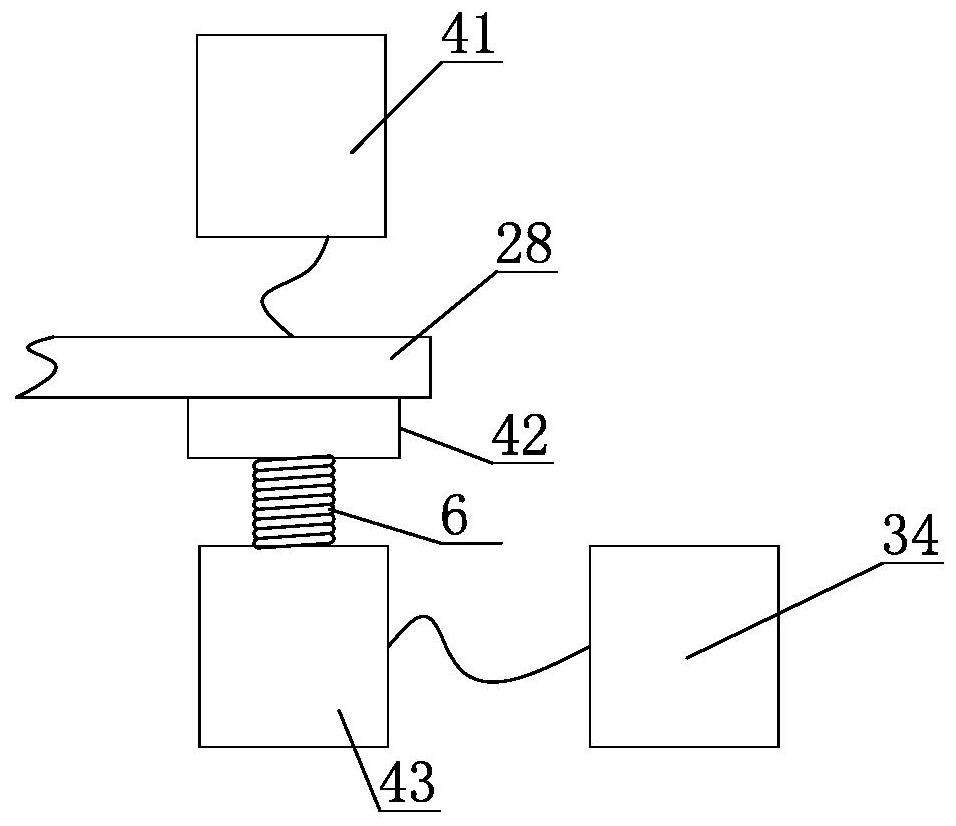

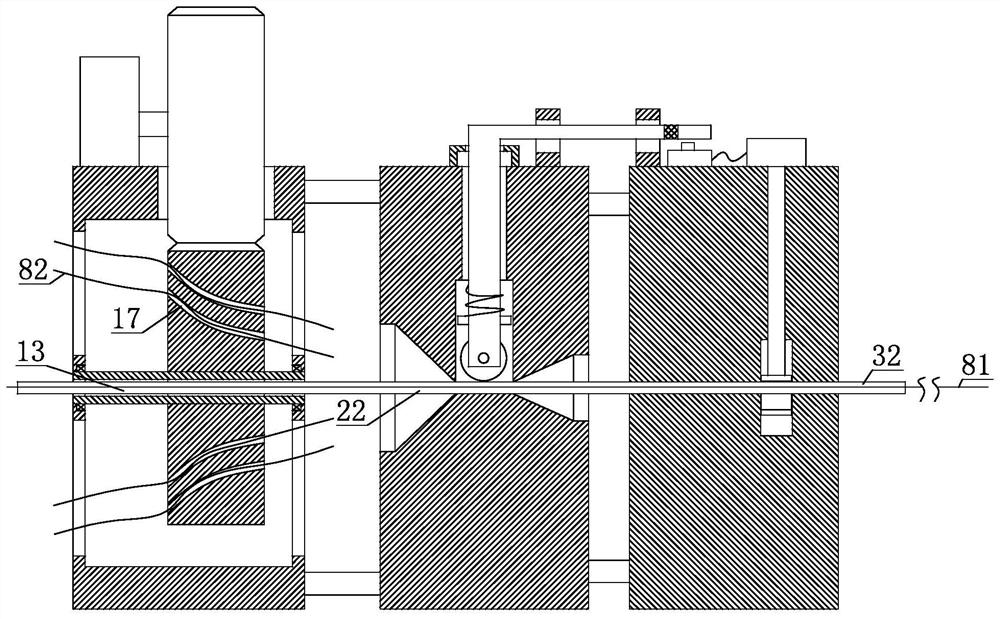

[0033] The present invention is an automatic winding device for pre-twisted wires of transmission lines, including a winding mechanism 1, the winding mechanism 1 includes a first support frame 11, and a rotating shaft 12 is arranged inside the first supporting frame 11, and the rotating shaft 12 is provided with a first routing channel 13 inside, the first routing channel 13 is located in the middle of the first support frame 11, the outer part of the rotating shaft 12 is provided with a first gear 14, and the upper part of the first support frame 11 is provided with Motor 15, the output end of described motor 15 is provided with second gear 16, and described second gear 16 is meshed with first gear 14, and described first gear 14 inside is provided with skein hole 17, and described winding mechanism 1 An induction mechanism 2 is provided on the side, and the induction mechanism 2 includes a second support frame 21. A second wiring channel 22 is provided inside the second suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com