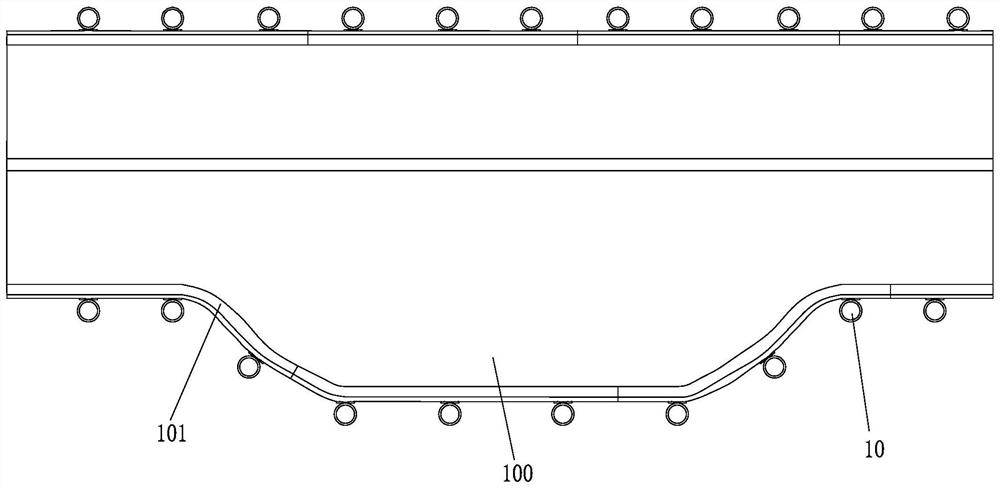

Auxiliary mounting device and mounting method for corrugated beam steel guardrail of bent road section

A technology for installing equipment and waveforms, applied to road safety devices, roads, roads, etc., can solve the problems of many operators, low installation efficiency, difficult docking, etc., to reduce weight and complexity, easy to carry, use, and operate Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

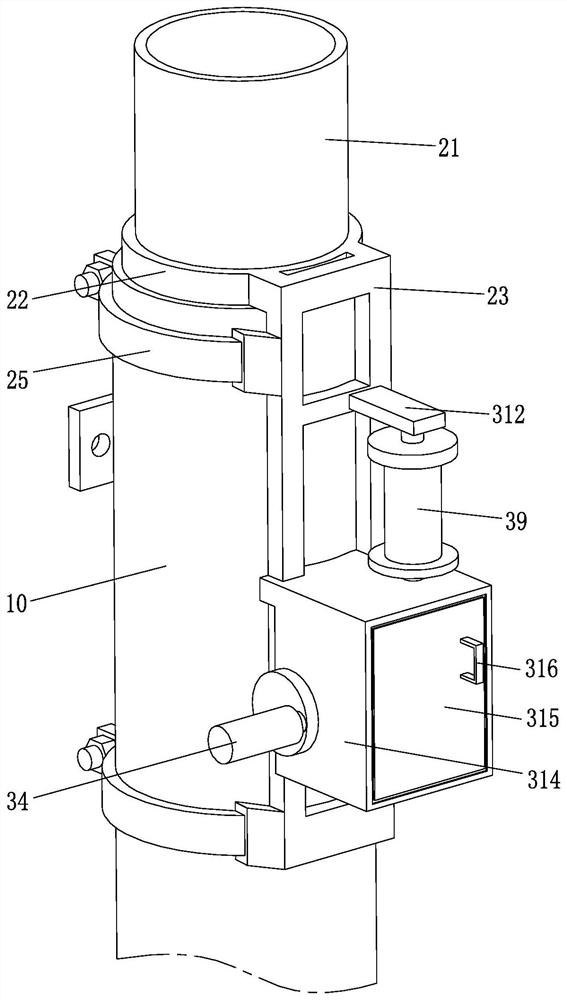

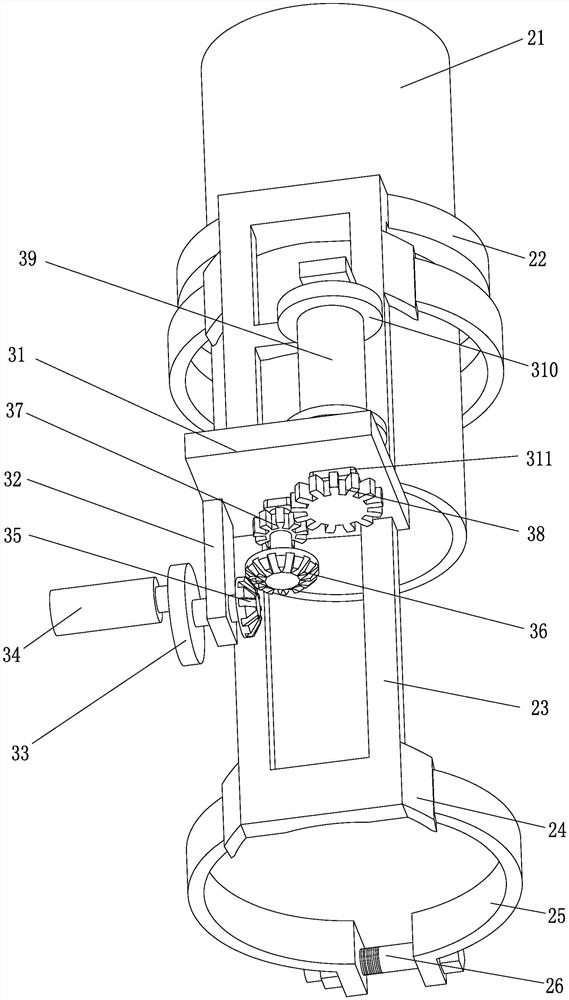

[0037] Such as Figure 2 to Figure 10 As shown, a wave beam steel guardrail auxiliary installation equipment for a curved road section of the present invention includes a wave beam steel guardrail pulling device 200, and the wave beam steel guardrail pulling device 200 includes an insertion rod 21, a support ring 22, a connecting frame 23, a To adjust the fastening assembly and the winding assembly, the insertion rod 21 is a hollow cylindrical shape in the center, and the insertion rod 21 is inserted into the hollow cylindrical hole in the center of the wave beam column 10 through the clearance fit of the shaft hole. In this embodiment, the outer surface of the insertion rod 21 The diameter is selected according to the inner diameter of the wave beam column 10, and the outer diameter of the inserting rod 21 is preferably 4-10 mm smaller than the inner diameter of the wave beam column 10. Due to the current specification "Wave Beam Steel Guardrail Part One: Two Wave Beam Steel G...

Embodiment 2

[0048] Such as Figure 2 to Figure 14As shown, on the basis of the structure in Embodiment 1, the corrugated beam steel guardrail clamp 300 in the auxiliary installation equipment for the corrugated beam steel guardrail of a curved section of the present invention includes a first splint 41, a splint hinge seat 42, a second splint 43, splint connecting block 44, splint connecting bolt 45, splint inner baffle plate 46, splint inner fixing seat 47 and pull ring 48, splint hinge seat 42 is located between the top of the first splint 41 and splint hinge seat 42, the first splint 41 and the top of the splint hinge seat 42 are hinged by the splint hinge seat 42, and a splint connecting block 44 is respectively fixed at the bottom contact of the first splint 41 and the splint hinge seat 42, and the two splint connecting blocks 44 pass through The splint connecting bolts 45 are connected, the inner side of the first splint 41 is fixed with a splint inner fixing seat 47 , the inside of...

Embodiment 3

[0053] Such as Figure 2 to Figure 14 As shown, the adjustable fastening assembly in the auxiliary installation equipment for the wave beam steel guardrail of a curved section of the present invention specifically includes a first hinge seat 24, a first sub-clamp 25 and a first long bolt 26, and the two first hinges The seat 24 is symmetrically arranged on the outside of the connecting frame 23, the rear end of the first sub-band 25 is hinged in the first hinged seat 24, and the front ends of the two first sub-bands 25 are respectively fixed with a hoop connection block 27, and the two The hoop connection blocks 27 are connected with the nuts through the first long bolt 26 and fixed by the hoop structure, which has simple structure, convenient operation and strong stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com