Inclined stand column combined partition and mounting method thereof

An installation method and technology of inclined uprights, which are applied in the field of combined partitions of inclined uprights and their installation, can solve the problems of construction errors, increase the difficulty of operation, and different problems, and achieve the effect of convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

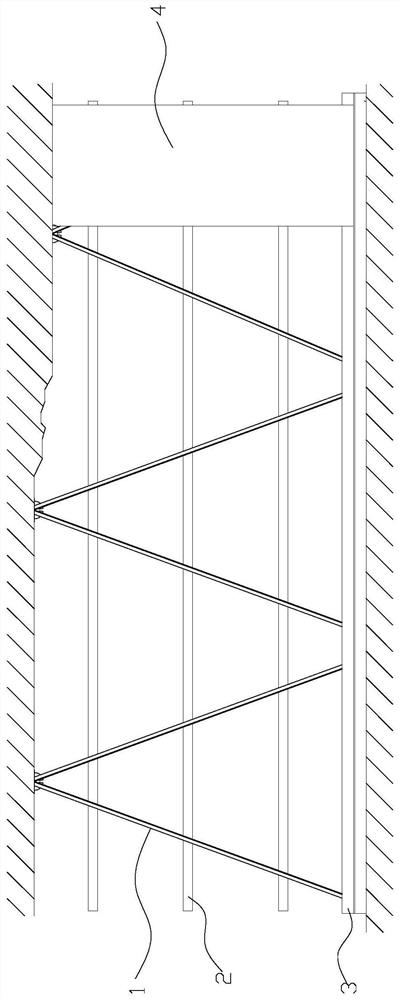

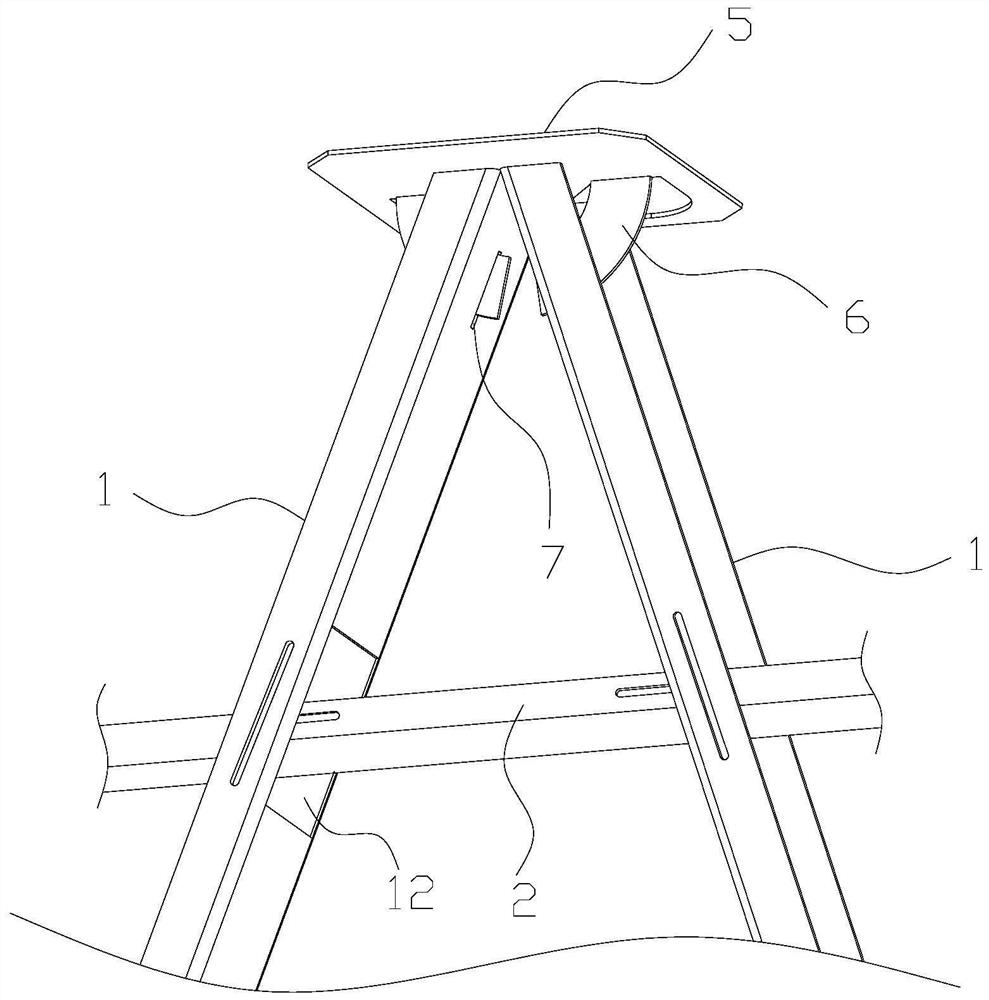

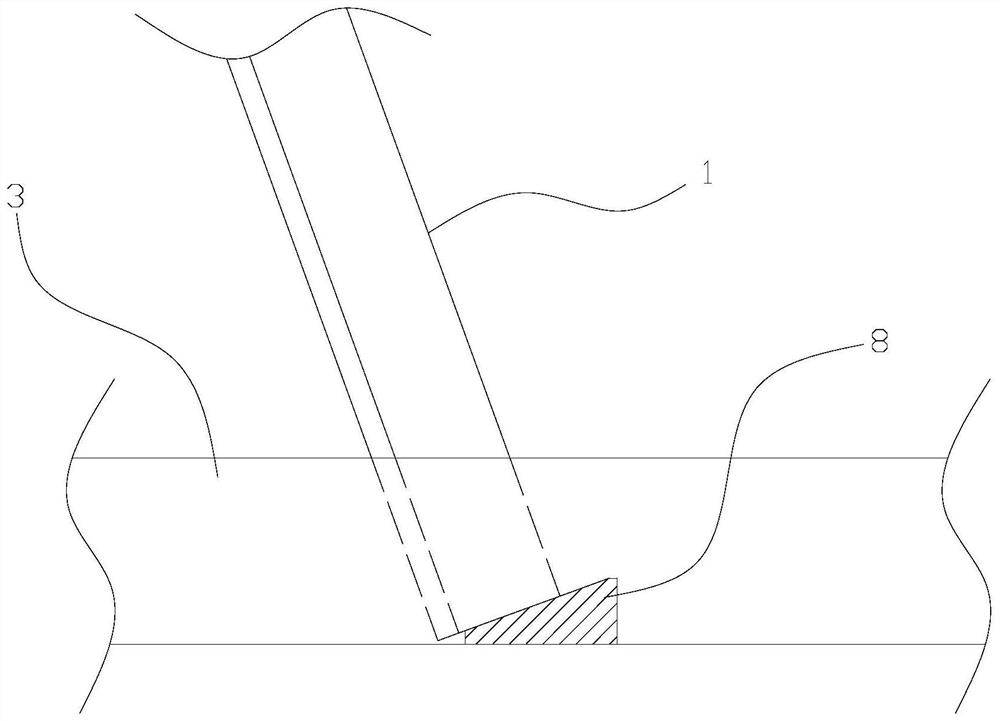

[0053]Seefigure 1 andFigure 4 The embodiment of the present invention provides a combined partition of inclined columns, including inclined columns 1, cross beams 2, bottom beams 3, and partition panels 4; inclined columns 1 are in two groups, and the top ends of each group of inclined columns 1 are connected together to make The two inclined columns 1 in each group are arranged in a figure eight shape. The top end of the inclined column 1 is set on the roof of the building, and the bottom end of the inclined column 1 is supported on the bottom beam 3; multiple beams 2 are arranged horizontally and fixedly arranged in On the multiple sets of inclined columns 1; the back side of the partition panel 4 is provided with a hook fitting part that cooperates with the beam 2, and the partition panel 4 is fixedly installed on the multiple beams 2 through the hook fitting part.

[0054]The present invention is different from the prior art, and adopts the structure in which the oblique columns 1 ...

Embodiment 2

[0071]This embodiment discloses the installation method of the inclined column combined partition of the first embodiment, which specifically includes the following steps:

[0072]S1. Lay the bottom beam 3 along the ground, and then set the inclined columns 1 in pairs in a figure-eight shape between the top of the building and the bottom beam 3, and arrange the inclined columns 1 along the bottom beam 3;

[0073]S2. The beam 2 is fixedly installed on the side of the inclined column 1, and multiple beams 2 are arranged at different heights;

[0074]S3. Lay the partition panels 4 one by one so that they are fixedly connected with the beam 2.

[0075]More specifically, the step S1 regarding the installation of the inclined column 1 specifically includes:

[0076]S1-1. Fix the bottom beam 3 along the ground;

[0077]S1-2. Lay out positioning between the top of the building and the bottom beam 3, and determine the top positioning point of each group of inclined columns 1;

[0078]S1-3. Open each group of inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com