Domestic hot water system and working method thereof

A technology for domestic hot water and working methods, which is applied to residential hot water supply systems, heating systems, heating methods, etc., can solve problems such as low heat exchange efficiency, electricity consumption, and poor water quality, so as to save operating costs and avoid The effect of uneven mixing and reduced electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

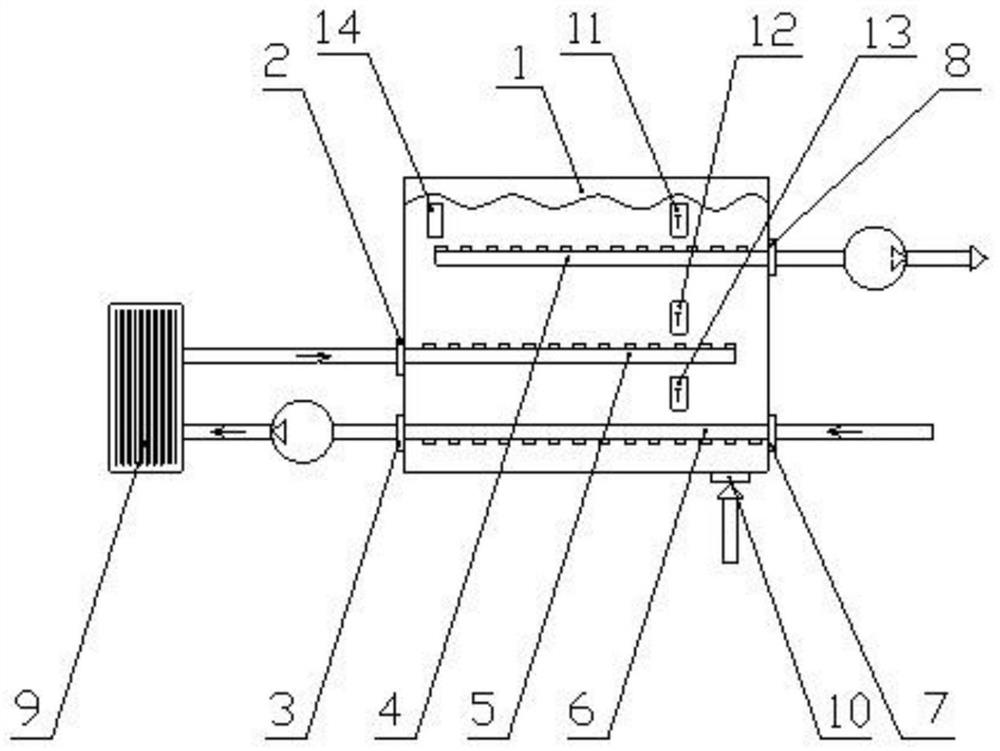

[0015] The domestic hot water system of the present invention includes a water tank 1, a hot water outlet 2 on the heating side, a cold water outlet 3 on the heating side, a water distribution tray 4 at the hot water outlet on the user side, a water distribution tray 5 at the hot water outlet on the heating side, and a water distribution tray at the user side. Water distribution tray 6, user side return water port 7, user side hot water port 8, heat exchanger 9, water replenishment port 10, upper water tank temperature sensor 11, water tank middle temperature sensor 12, water tank lower temperature sensor 13, water level gauge 14.

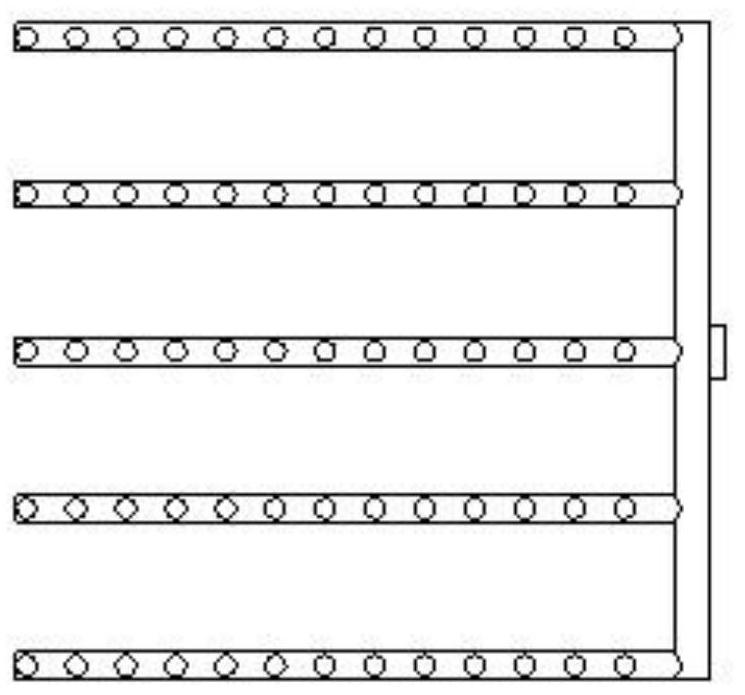

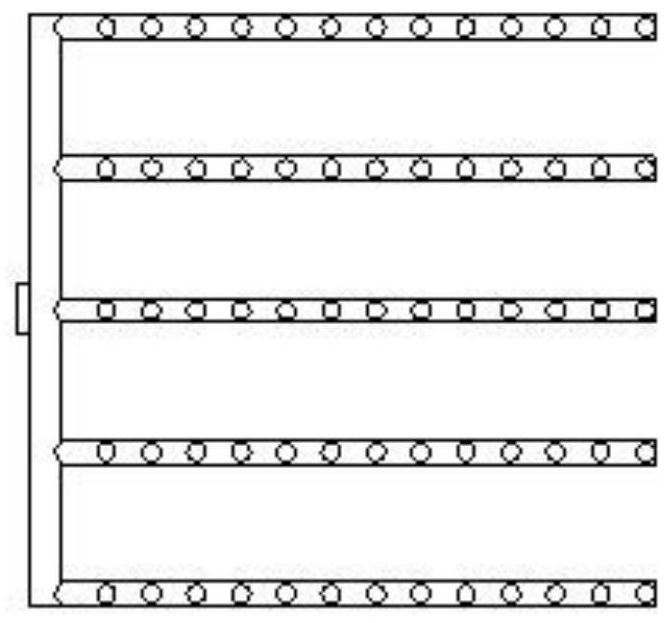

[0016] like Figure 1-4 As shown: the hot water port 8 on the user side of the water tank 1 is on the upper part of the side of the water tank 1, and there is a water distribution plate 4 for the user side hot water port in the upper part of the water tank 1, and the water distribution hole of the water distribution plate 4 of the user side hot wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com