Monitoring method and device for real-time working condition of catalytic reforming device

A technology of catalytic reforming and real-time working conditions, applied in special data processing applications, instruments, complex mathematical operations, etc., can solve problems such as flooding of alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

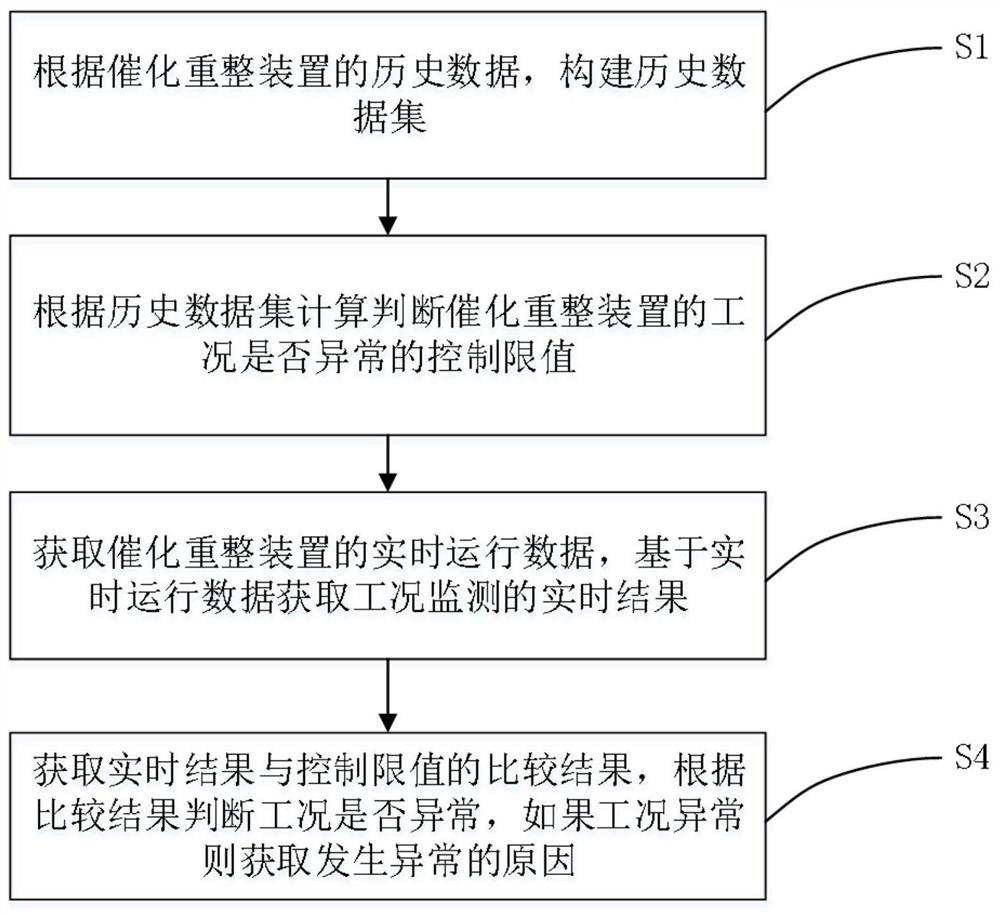

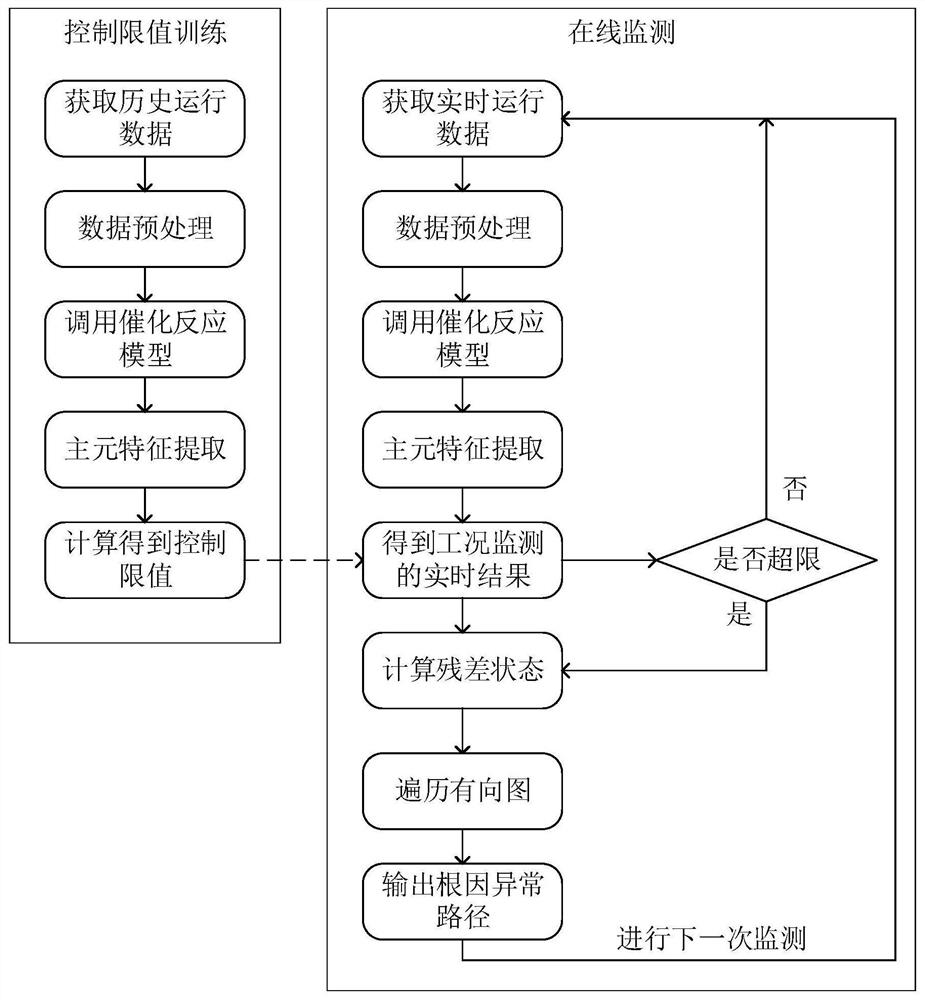

[0065] Such as figure 1 As shown, the present invention proposes a monitoring method for the real-time working condition of catalytic reforming unit, comprising:

[0066] S1: Construct a historical data set based on the historical data of the catalytic reformer.

[0067] In this embodiment, the operating data of the catalytic reforming device in each process section is collected through the deployed instrumentation device and data acquisition device, and the operating data includes reaction condition data, reaction inlet and reaction outlet of the catalytic reforming device component data. Then the collected data is mapped to the calculation model according to the corresponding device tag number, so that the collected data can be processed and calculated later. After the operating data is collected, the operating data must first be preprocessed to filter out invalid data in the operating data, such as outlier data generated by skipping tables, dead line data generated due to...

Embodiment 2

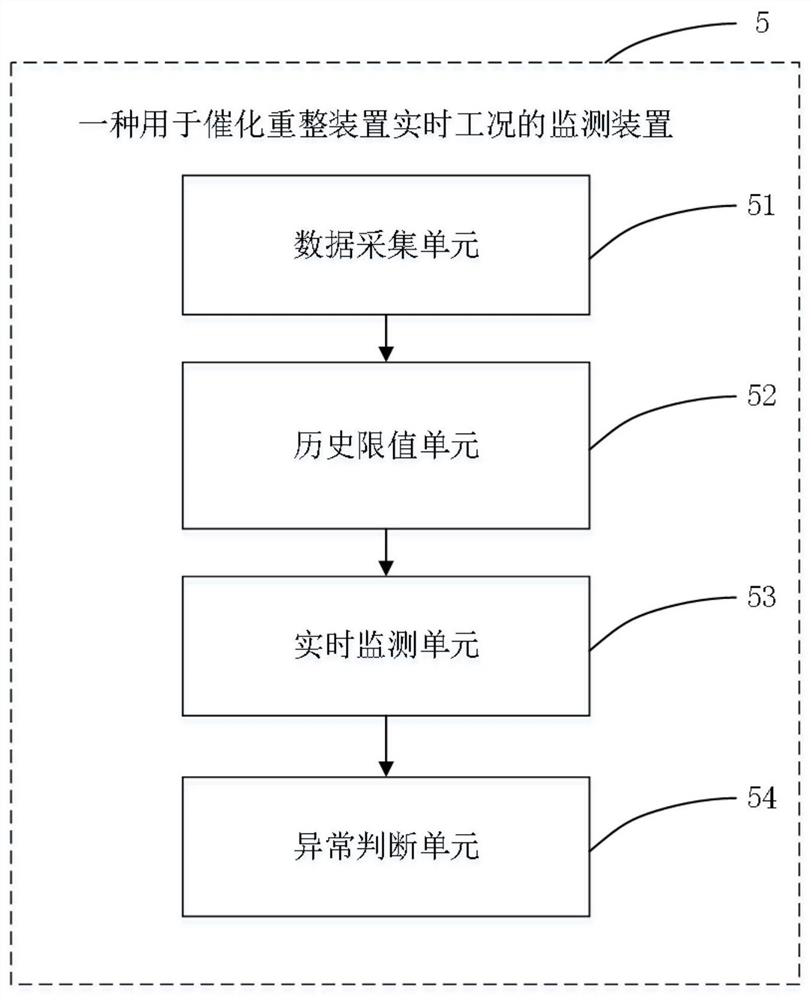

[0127] Such as image 3 As shown, the present invention also proposes a monitoring device 5 for the real-time working condition of the catalytic reformer, comprising:

[0128] Data collection unit 51: for constructing a historical data set according to the historical data of the catalytic reforming unit;

[0129] Historical limit value unit 52: used to calculate the control limit value for judging whether the working condition of the catalytic reformer is abnormal according to the historical data set;

[0130] Real-time monitoring unit 53: used to obtain real-time operating data of the catalytic reformer, and obtain real-time results of working condition monitoring based on the real-time operating data;

[0131] Abnormality judging unit 54: used to obtain the comparison result between the real-time result and the control limit, judge whether the working condition is abnormal according to the comparison result, and obtain the cause of the abnormality if the working condition i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com