Power industry operation and maintenance scheduling system capability management method

A capability management, power industry technology, applied in the field of operation and maintenance, can solve the problems of passive operation and maintenance personnel, low efficiency, lack of operation and maintenance scheduling mechanism, lack of efficient operation and maintenance technical tools, etc., to achieve the effect of improving operation and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

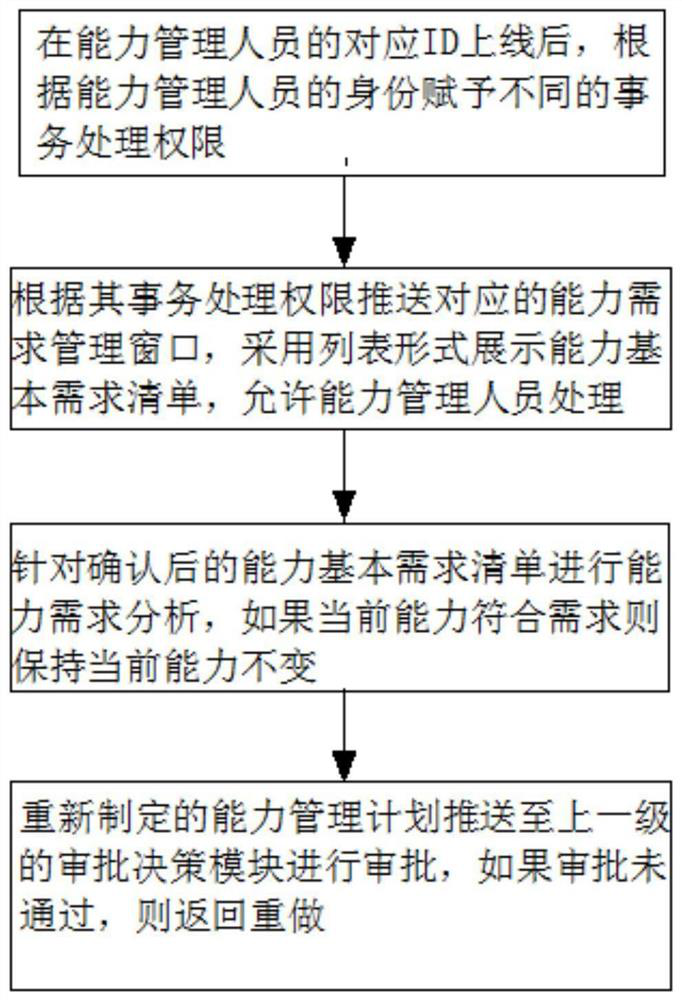

[0030] Such as figure 1 As shown, the power industry operation and maintenance dispatching system capacity management method of the present invention includes the following steps:

[0031] Step S1: After the corresponding ID of the capacity management personnel is online, grant different transaction processing permissions according to the identity of the capacity management personnel;

[0032] Step S2: Push the corresponding capability requirement management window according to its transaction authority, display the list of basic capability requirements in a list form, and allow capability managers to delete, mark and prioritize the options in the basic capability req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com