Manufacturing method of antenna assembly, antenna assembly and electronic equipment

An antenna assembly and manufacturing method technology, applied in the field of electronic equipment, can solve problems such as the impact of waterproof and reliability of the whole machine, affecting user experience, etc., and achieve the effect of improving the ability to send and receive information, ensuring width, waterproofness and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

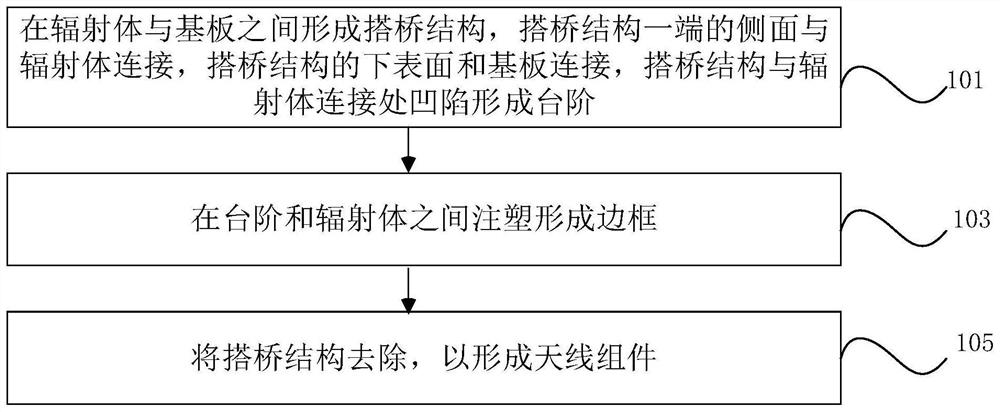

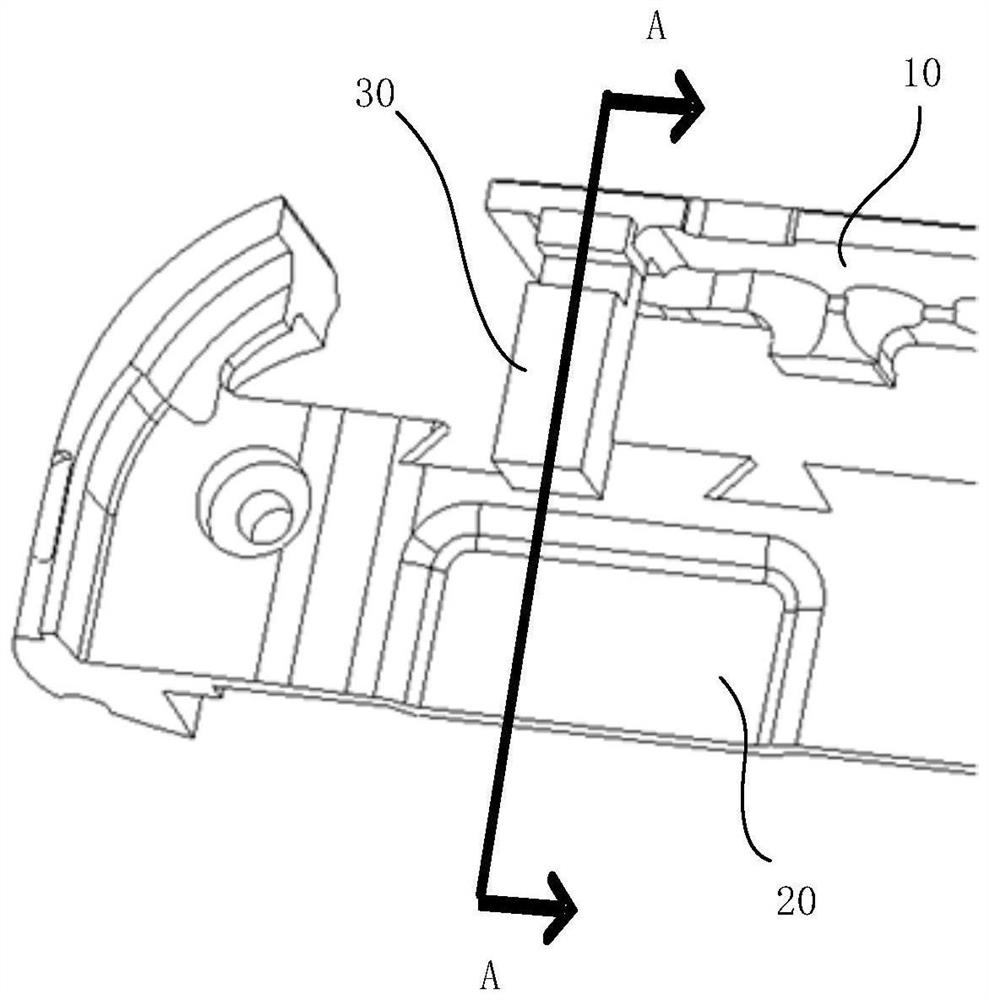

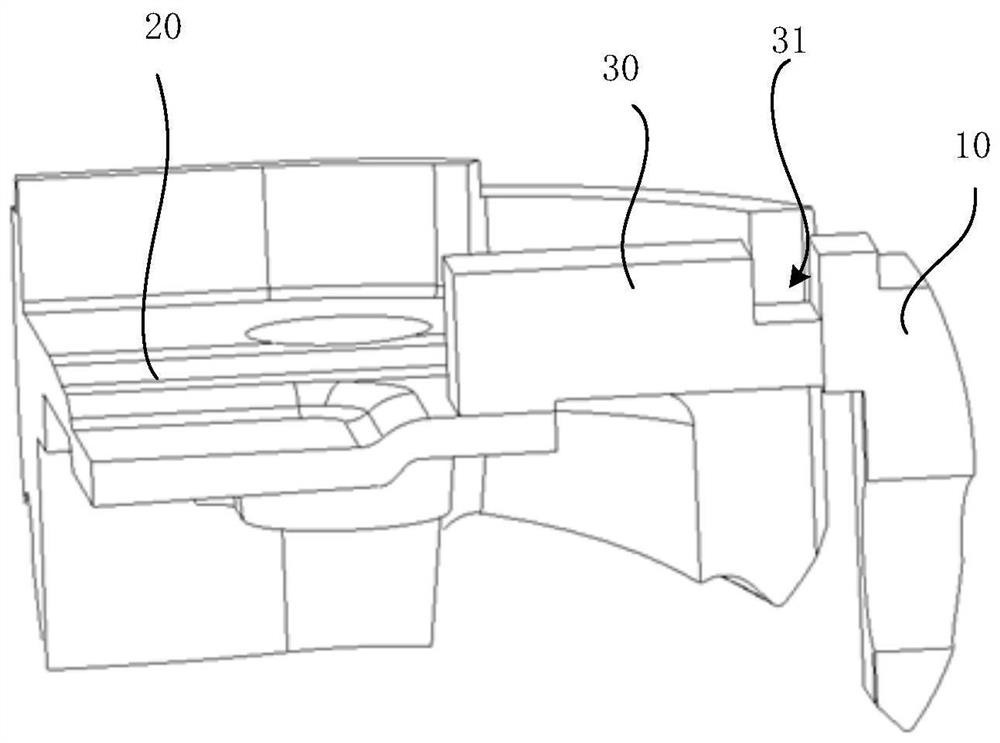

[0059] figure 1 It is a schematic flowchart of a method for manufacturing an antenna assembly provided by an embodiment of the present invention, figure 2 It is a schematic structural diagram of the connection between the radiator and the substrate in a method for manufacturing an antenna assembly provided by an embodiment of the present invention, image 3 for figure 2 A cross-sectional view of the radiator-to-substrate connection along section line A provided in , Figure 4 It is a schematic structural diagram of the connection between the radiator, the substrate and the frame in a method for manufacturing an antenna assembly provided by an embodiment of the present invention, Figure 5 for Figure 4 The cross-sectional view of the radiator, substrate and frame connection along the cutting line B provided in Image 6 It is a schematic diagram of the structure of the radiator, the substrate and the frame after the bridging structure is removed in the method of manufactu...

Embodiment 2

[0122] Another aspect of the embodiments of the present invention provides an antenna assembly, which is manufactured by using the manufacturing method of the antenna assembly provided in the first embodiment.

[0123] The antenna assembly provided by the embodiment of the present invention is made by the manufacturing method of the assembly provided by Embodiment 1, which can increase the clearance area of the antenna structure and improve the ability of the antenna structure to send and receive information without changing the size of the electronic device. Can effectively guarantee the width of the dispensing surface.

Embodiment 3

[0125] Another aspect of the present invention provides an electronic device, including the antenna assembly and the control circuit provided in Embodiment 2, wherein the antenna assembly and the control circuit are electrically connected.

[0126] The electronic device may include: a cover plate, a display screen, a control circuit, a battery, a housing, front and rear cameras, an unlocking module, an antenna assembly, and the like.

[0127] Wherein, the cover plate is installed on the display screen to cover the display screen, and the cover plate may be a transparent glass cover plate so that the display screen can be displayed through the cover plate.

[0128] The housing can form the outer contour of the electronic device. In some embodiments of the present invention, the housing can include a middle frame and a rear cover, the middle frame and the rear cover are combined to form a housing, and the middle frame and the rear cover can form a storage space for Storage contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com