Power strip easy to plug and unplug

A plug-in and inter-plug technology, which is applied to the parts of the connecting device, electrical components, coupling devices, etc., can solve the problems of reducing the service life of the plug-in, damage to the plug-in, and reducing the deformation of conductive copper sheets, so as to avoid electric shock, Prevent electric shock, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

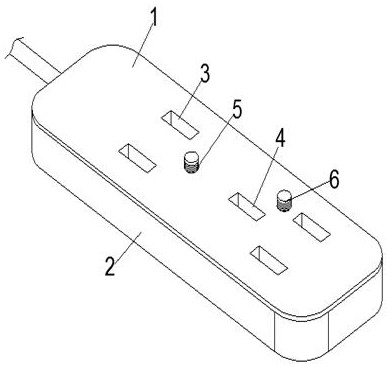

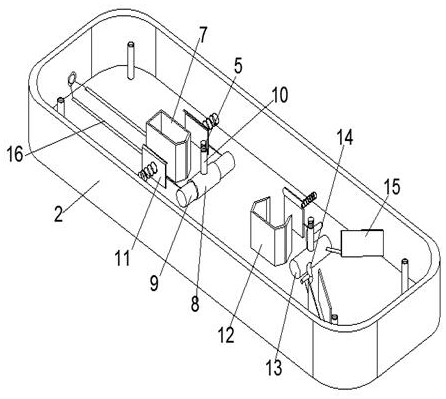

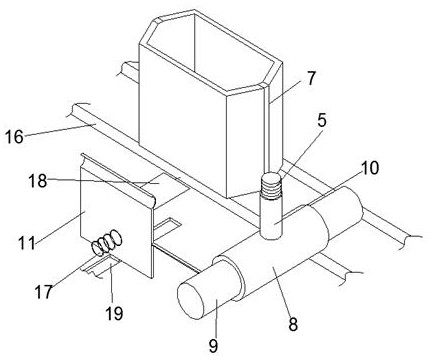

[0022] Such as Figure 1-7 As shown, an easy-to-plug plug-in strip includes a plug-in top cover 1, a plug-in housing 2, a two-phase socket 3, a three-phase socket 4, a first screw rod 5, and a second screw rod 6. The above plug-in cover 1 is connected to the plug-in housing 2 through screws, one side of the plug-in housing 2 is provided with connecting wires, and the plug-in cover 1 is provided with two-phase sockets 3 and three-phase sockets 4. There is a certain distance between the phase jack 3 and the three-phase jack 4, the first screw mandrel 5 is arranged below the two-phase jack 3, and the second screw mandrel 6 is arranged on one side of the three-phase jack 4, and the Both the first screw mandrel 5 and the second screw mandrel 6 are threadedly connected to the sleeve 10, and the sleeve 10 located at the duplex socket 3 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com