Tire tread including sipes and sipes

一种轮胎胎面、胎面的技术,应用在胎面花纹领域,能够解决增加单位行驶距离行驶成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the drawings easier to understand, the same reference numerals may be used to describe different variants of the invention, wherein the reference numerals refer to the same kind of elements, both structurally and functionally.

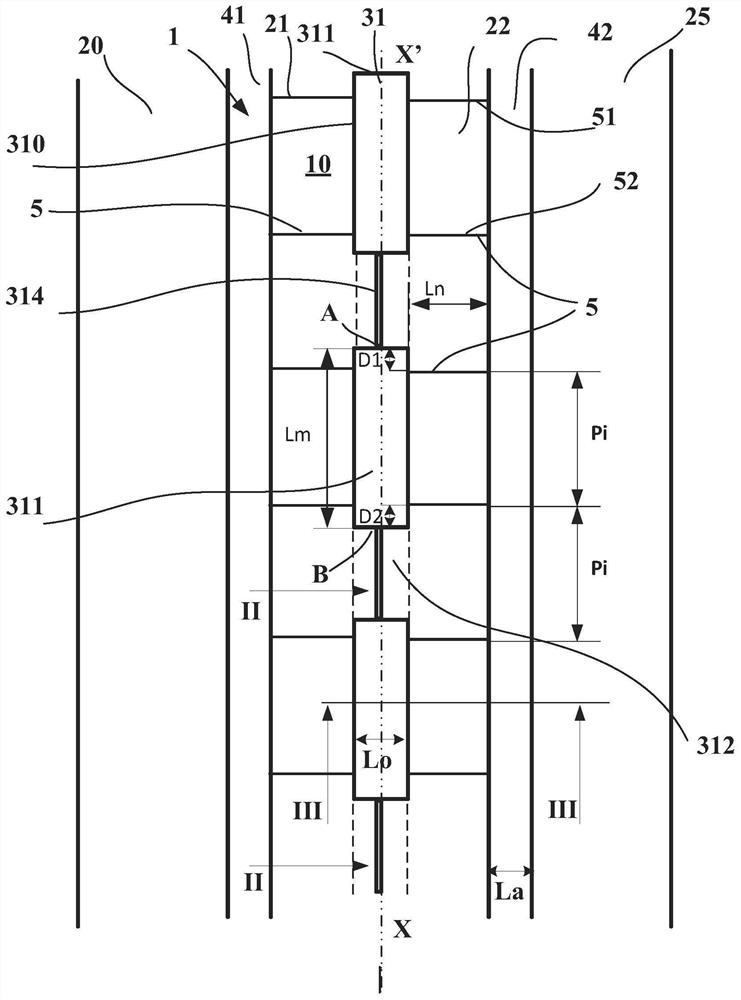

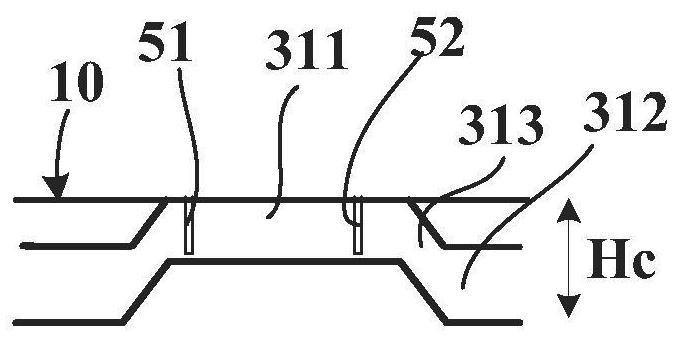

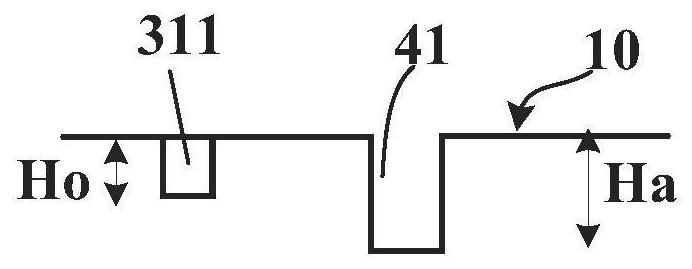

[0053] refer to figure 1 , a first variant of the invention describes a tread 1 having a tread surface 10 intended to be in contact with the road surface when the tire provided with said tread is running. This tread 1 has a thickness of the material to be worn during running in which cuts, grooves or sipes are formed.

[0054] figure 1 A view is shown of the tread surface 10 of the tread comprising three circumferentially oriented grooves 31, 41, 42 (running in the circumferential direction indicated by the line XX'). These three grooves delimit two intermediate circumferential ribs 21 , 22 and two peripheral ribs 20 , 25 located axially outside. These two grooves 41, 42 are cuts open over the entire groove length on the trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com