Tyre tread comprising complex grooves and incisions

A tire tread and tread technology, applied in the field of tread patterns, can solve the problems of poor noise performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

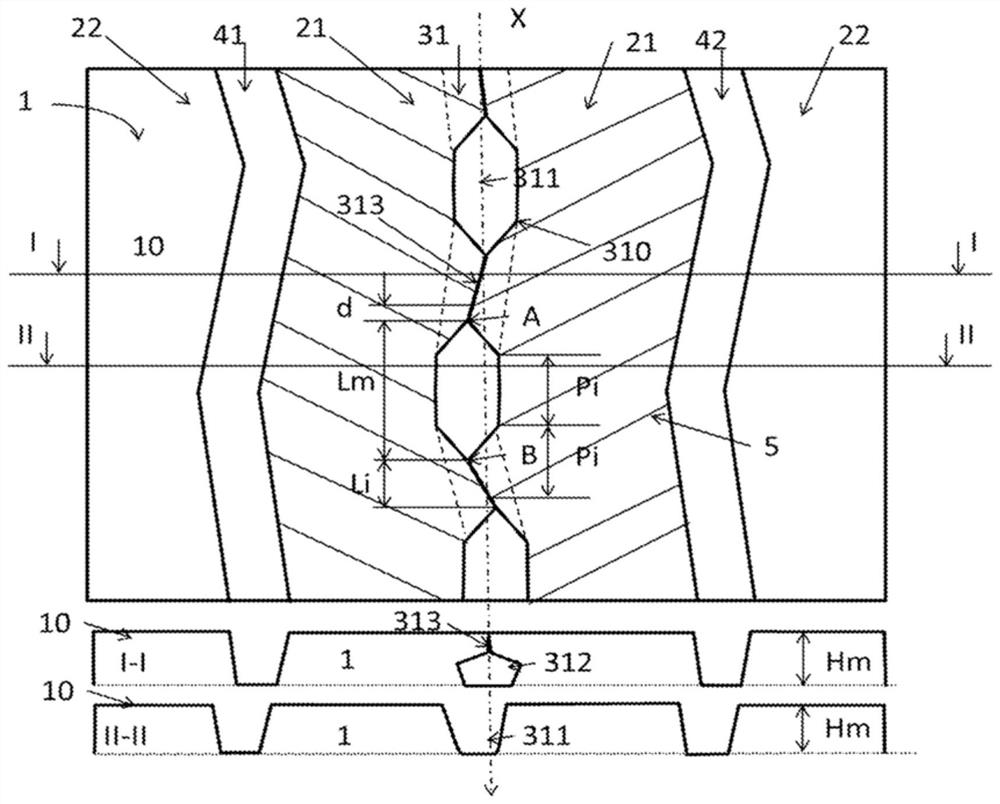

[0069] The invention was tested on heavy vehicle tires of size 315 / 70R 22.5.

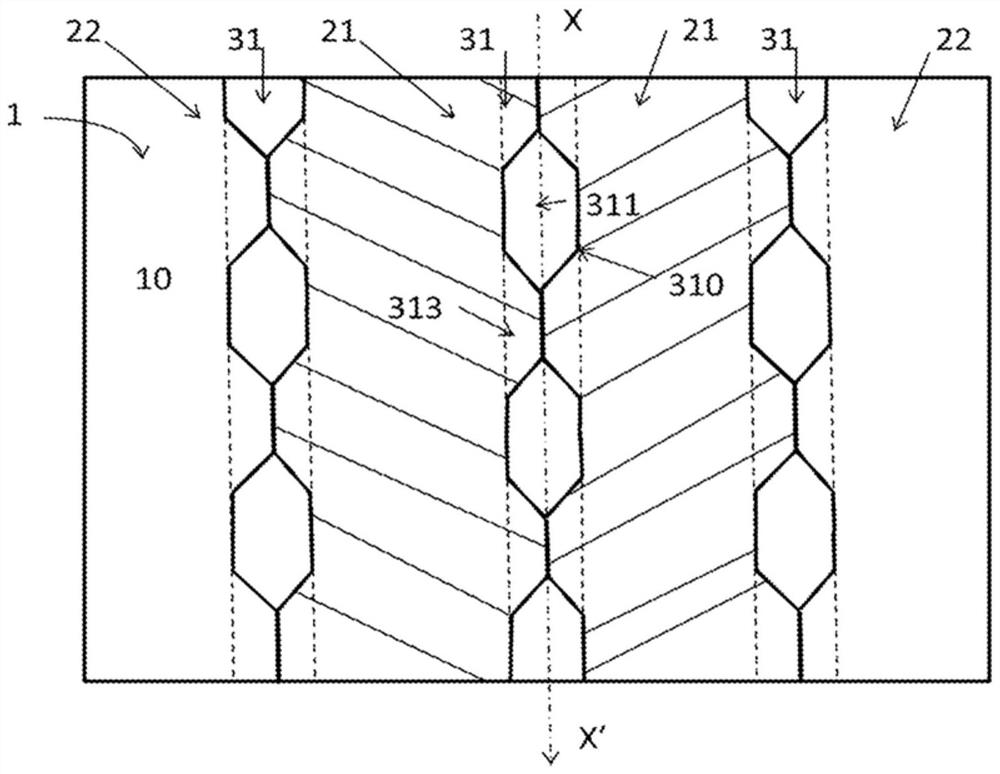

[0070] This tread 1 has a width W equal to 265 mm and a thickness of abraded material equal to 13 mm; it is provided with a tread pattern formed by five circumferentially oriented composite grooves of a depth equal to 13 mm.

[0071] The compound groove has an outer cavity, which opens to the tread surface when new, and an inner cavity, which is hidden within the tread. These outer cavities and inner cavities are joined together to form compound grooves over the entire circumference of the tire. The average width of these internal and external cavities is equal to 8 mm. The depth of the outer cavity and the inner cavity is equal to 13mm.

[0072] The external cavity 311 has, on the tread surface 10 , an elongated, symmetrical octagonal profile 310 when new, said profile 310 having a mean length Lm equal to 33 mm in this variant. These external cavities 311 are arranged at a pitch equal to 66 mm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com