Guide shoe for a lift and method for producing a guide shoe

A sliding guide shoe and a technology for guide shoes are applied in the field of manufacturing sliding guide shoes for elevators, which can solve the problems of complex and expensive manufacturing of sliding guide shoes, and achieve the effects of simple cost, low cost and simplified mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

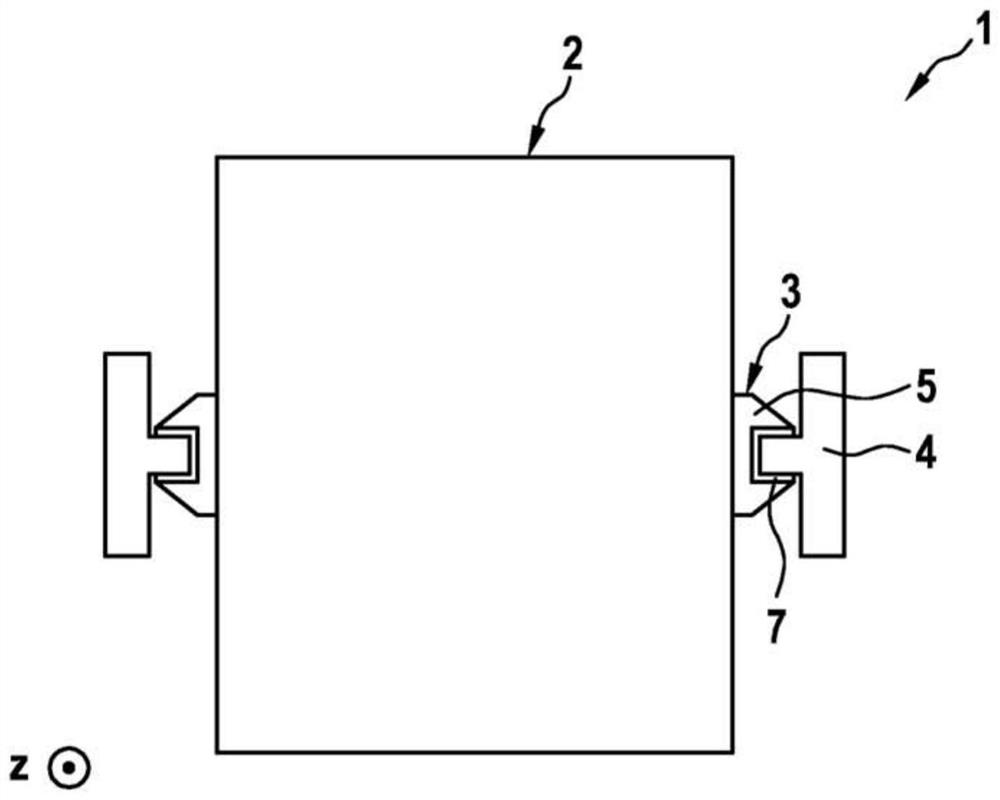

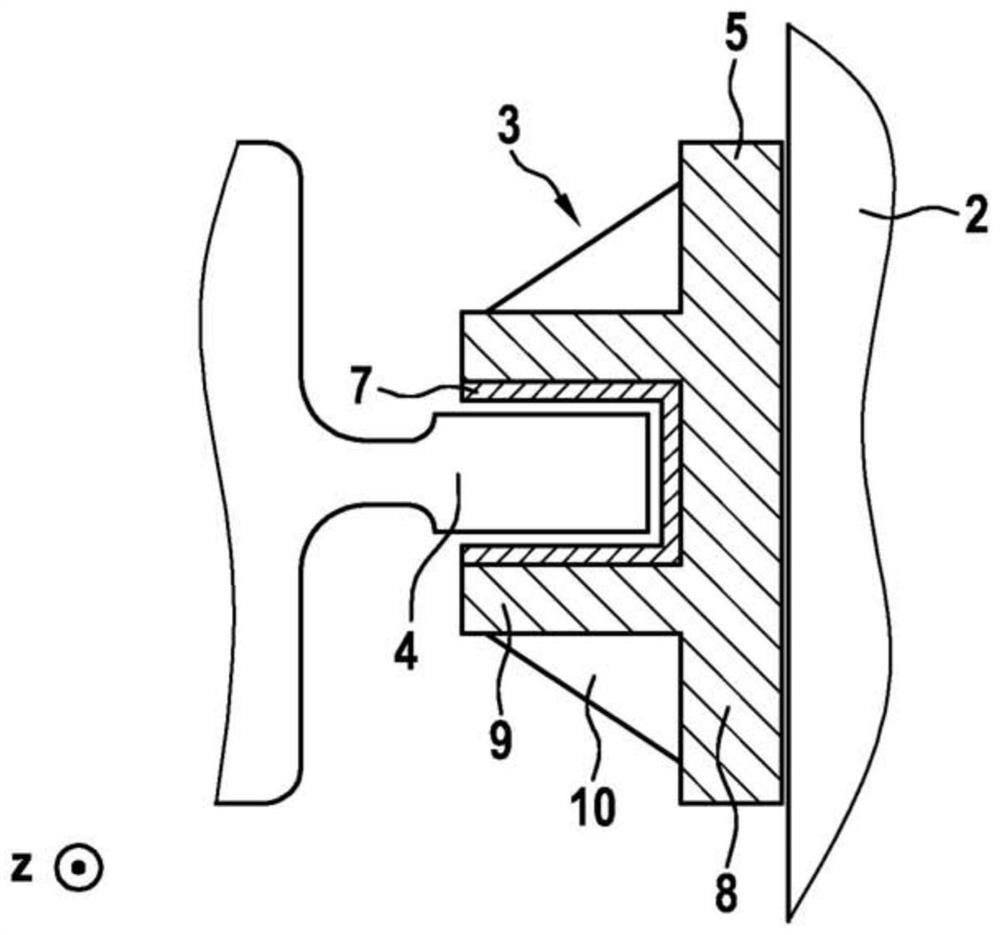

[0047] figure 1 An elevator is shown generally at 1 with an elevator car 2 which can be moved vertically between two guide rails 4 in a not shown elevator shaft up and down in the z-direction. In the present case, the linear guide with the guide rail 4 is formed, for example, from a T-shaped profile extending in the longitudinal direction z. At least one sliding guide shoe 3 for guiding the car 2 is arranged on each side of the car 2 . For optimal guidance, elevator cars usually have four (two on each side) or more sliding guide shoes. Likewise, a counterweight, not shown, connected to the car by means of carrying means in the form of ropes or belts, may have similarly designed sliding guide shoes (not shown here) for guiding the counterweight on the counterweight guide rails.

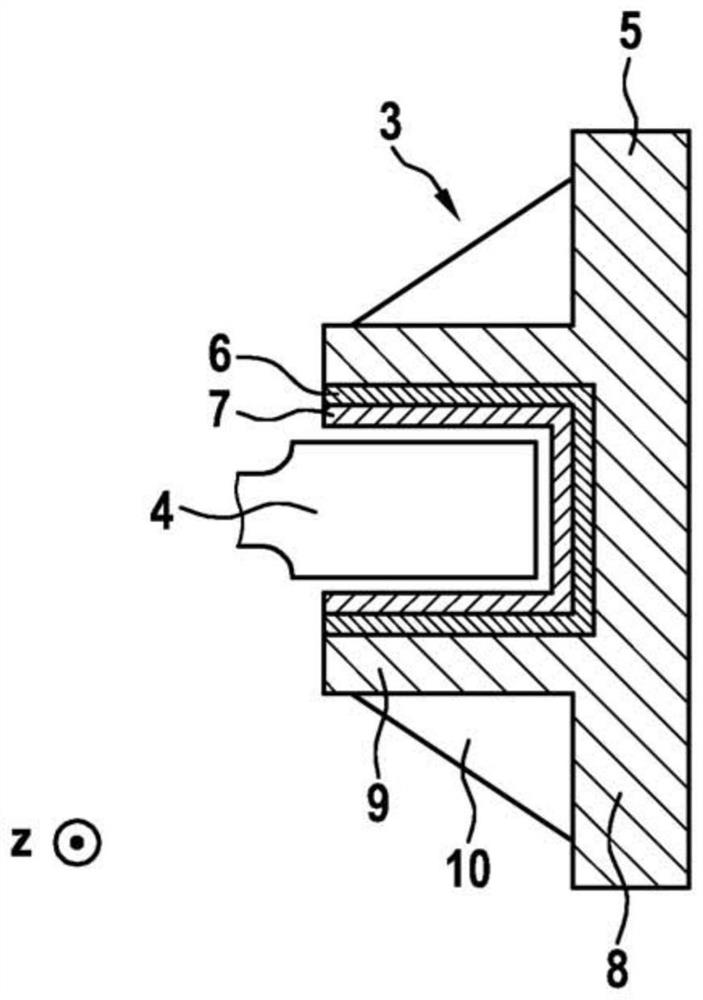

[0048] The sliding guide shoe 3 basically consists of two components in a manner known per se: a guide shoe housing 5 and a sliding element 7 . The guide shoe housing 5 is used on the one hand to ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com