Dust-free non-bag high-efficient pulverizer

A pulverizer and high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of narrow design of return air passage, inability to effectively reduce the air pressure of the discharge hopper, and poor circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

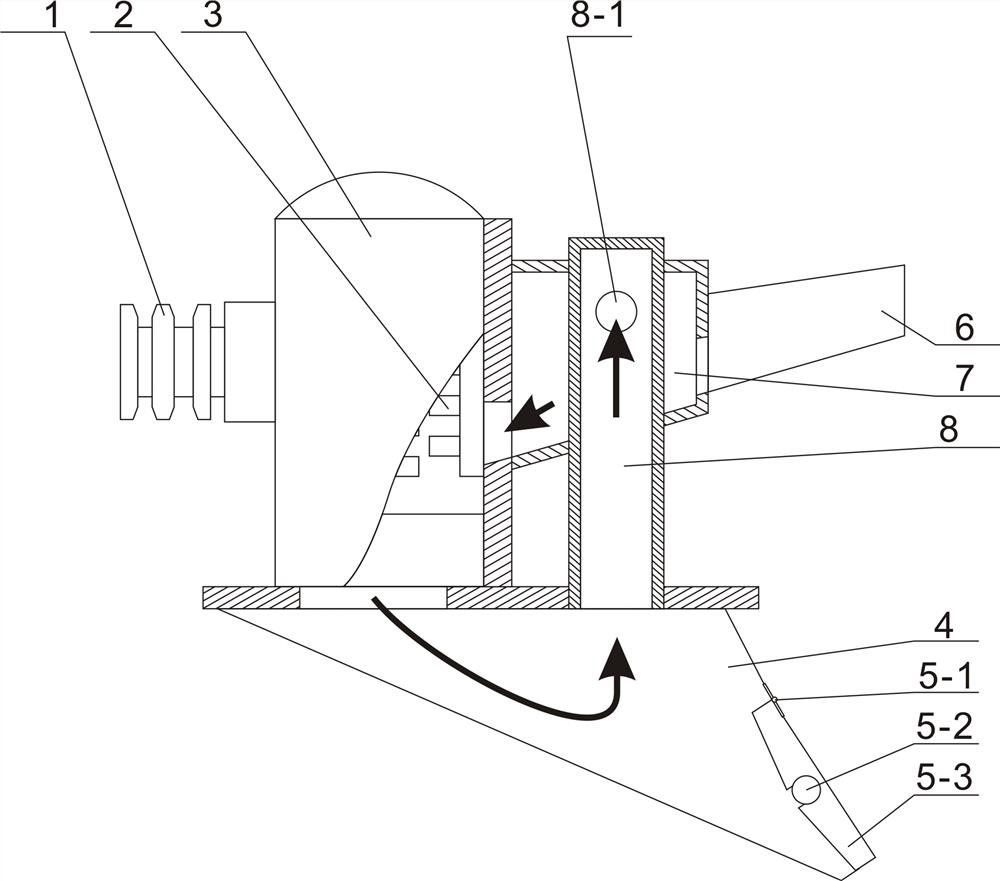

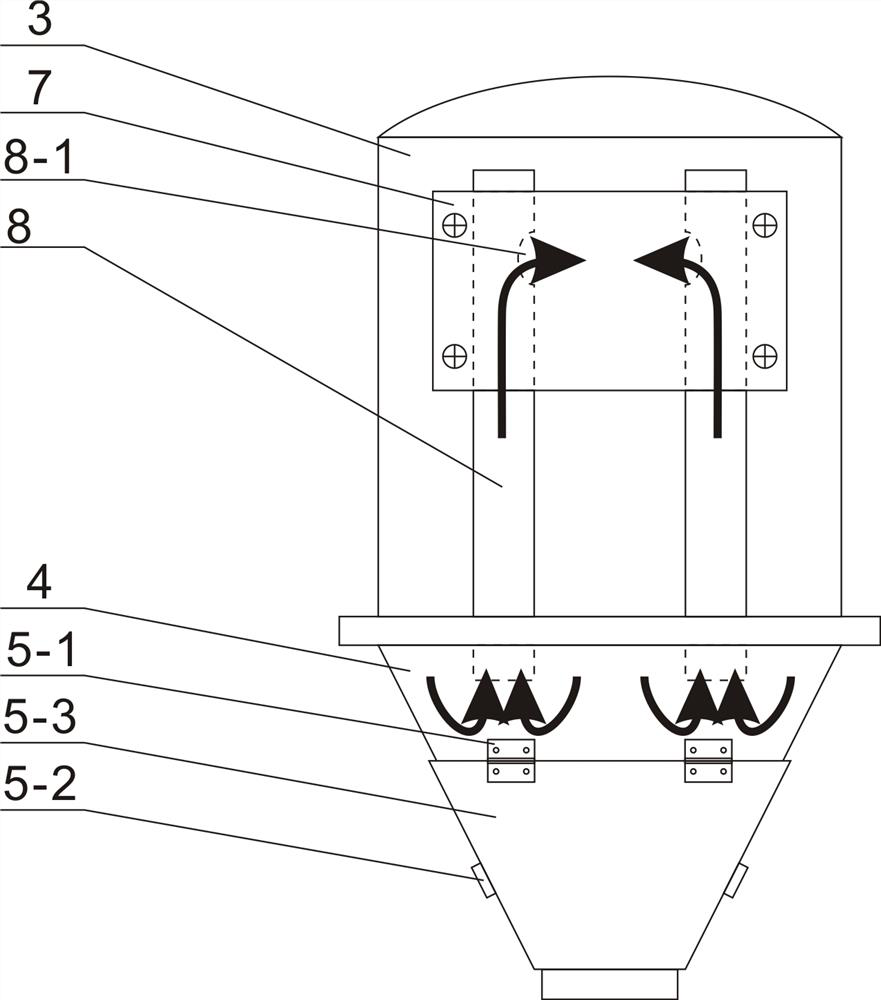

[0015] Embodiment 1, see attached Figure 1-2 , a dust-free and bag-free high-efficiency pulverizer, comprising a driving force wheel 1, a hopper 6, a hopper 4, a pulverization chamber 3, and a pulverization device in the pulverization chamber, and is characterized in that: a round is added between the hopper and the pulverization chamber Bellows 7, and the air return box is communicated with the discharge hopper through the return pipe 8, and the outlet of the discharge hopper is adjusted by the regulating device 5 to adjust the size of the outlet.

[0016] The crushing device is a claw-type crushing device 2, which is mainly composed of a body, a valve, a rotor disc, a toothed disc, a sieve, a belt disc, a hopper, etc. When the power wheel drives the belt disc to rotate, the high-speed rotating claws and Raw materials collide to achieve a crushing effect.

[0017] The structure of the adjustment device is: at the outlet of the hopper, a cover plate 5-3 is hinged through a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com