Frame forming device and forming method

A technology of forming device and frame, applied in vehicle parts, transportation and packaging, etc., can solve the problems of long production line, high production cost, slow production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

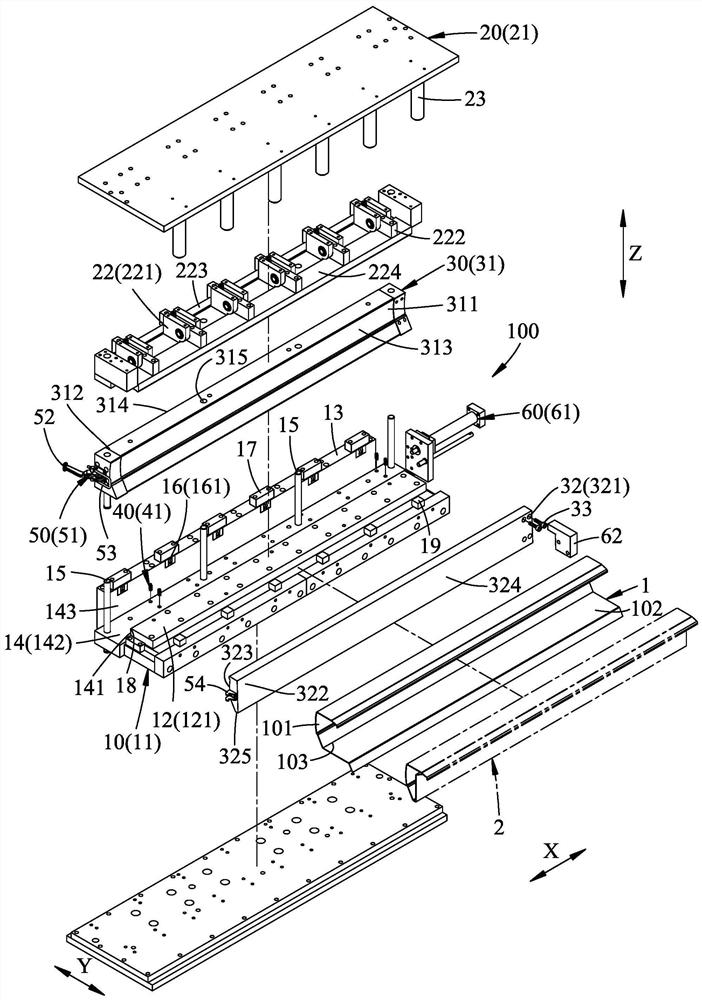

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

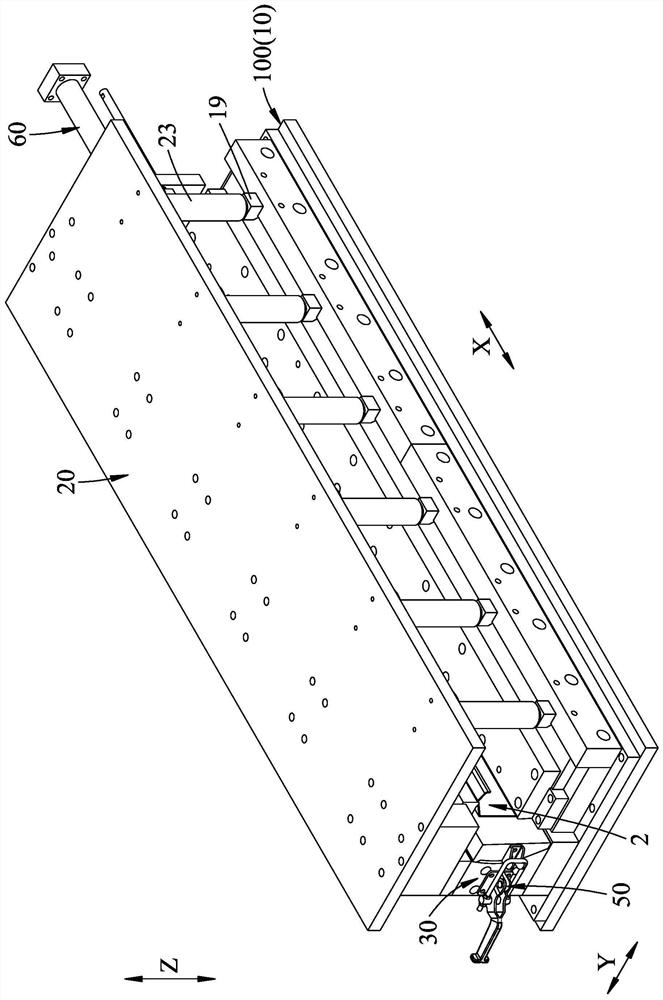

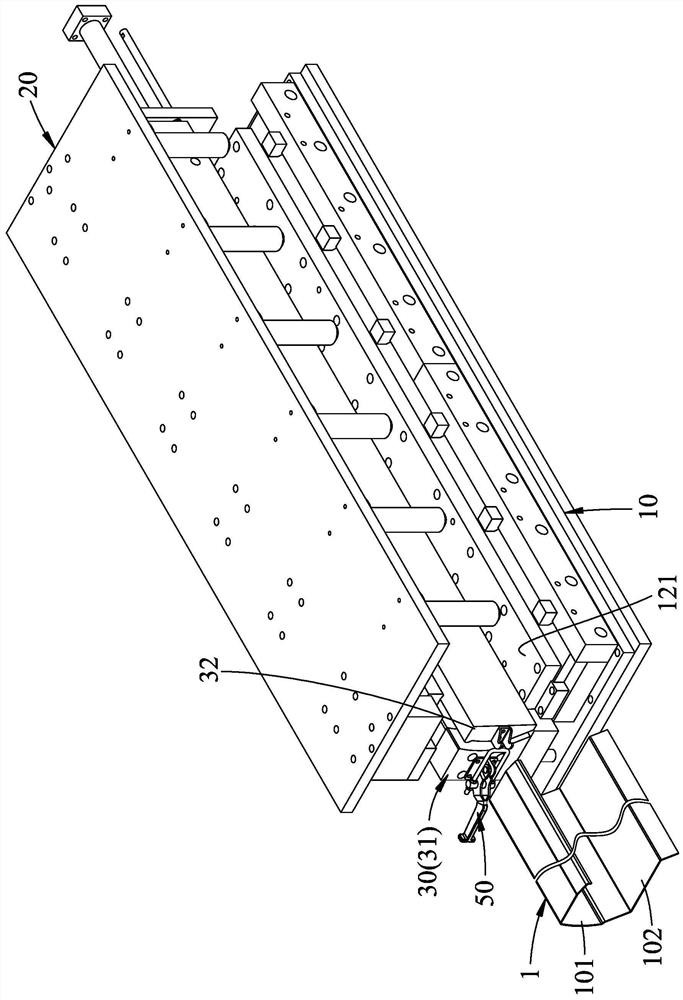

[0026] refer to figure 1 and figure 2 , an embodiment of the vehicle frame forming device 100 of the present invention is suitable for bending a metal plate 1 into a hollow tubular exercise bike frame 2, the metal plate 1 of this embodiment has been preformed, and is perpendicular to a first The cross-sectional shape in the axial direction X is generally U-shaped, and has an inverted L-shaped first part 101, a second part 102 intersecting and connecting with the first part 101, and a 102 between the transition portion 103 .

[0027] The molding device 100 includes a base unit 10 , a top unit 20 , a molding unit 30 , an elastic unit 40 , a buckle 50 , and a pushing unit 60 .

[0028] The base unit 10 extends along the first axis X, and includes a base 11, a front seat 12 fixed on the base 11, a second axis Y perpendicular to the first axis X and the The fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com