A kind of plate strong deformation device and its technology

A deformation device and plate technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of uneven strain, easy formation of defects, difficult alignment of materials, etc., to strengthen metal plates, improve strength, grain size The effect of uniform refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The 5083 aluminum alloy plate blank with a cross section of 40mm×5mm and a length of 500mm is subjected to strong deformation processing at room temperature, and the specific operations are as follows:

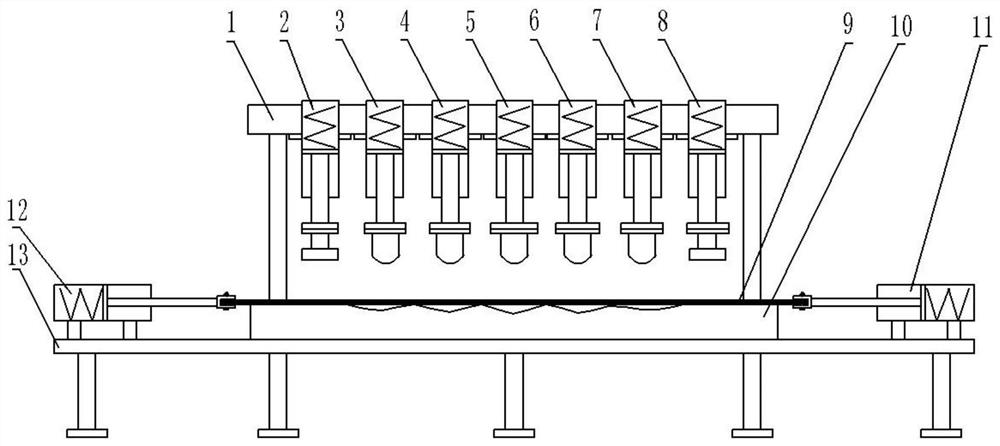

[0055] S1. Refer to the attached figure 1 The first hydraulic cylinder 2, the second hydraulic cylinder 3, the third hydraulic cylinder 4, the fourth hydraulic cylinder 5, the fifth hydraulic cylinder 6, the sixth hydraulic cylinder 7, and the seventh hydraulic cylinder 8 assembled with the lower pressure head are assembled to Crossbeam 1 on the rack. Assembling the die 10, the first traction hydraulic cylinder 12 and the second traction hydraulic cylinder 11 to the frame lower beam 13;

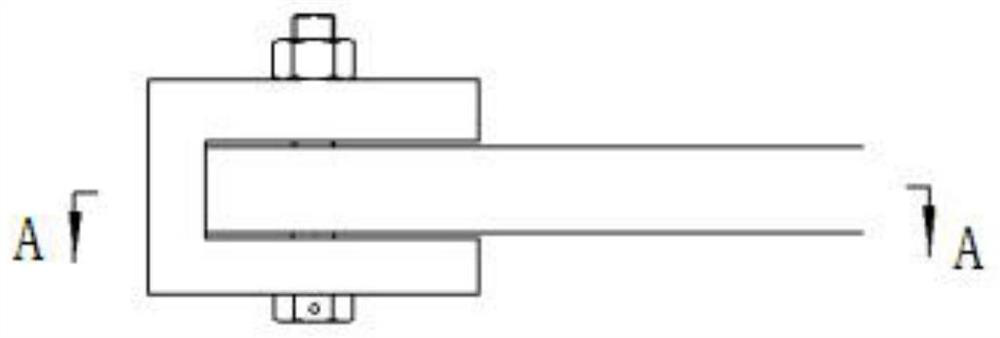

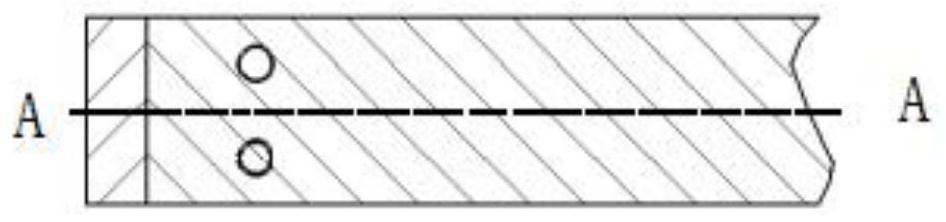

[0056] S2. Refer to the attached figure 1 The sheet metal blank 9 is connected with the first traction hydraulic cylinder 12 and the second traction hydraulic cylinder through bolts sequentially, and covered on the die 10 . Reference attached Figure 5 Make the hydraulic cylinder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com