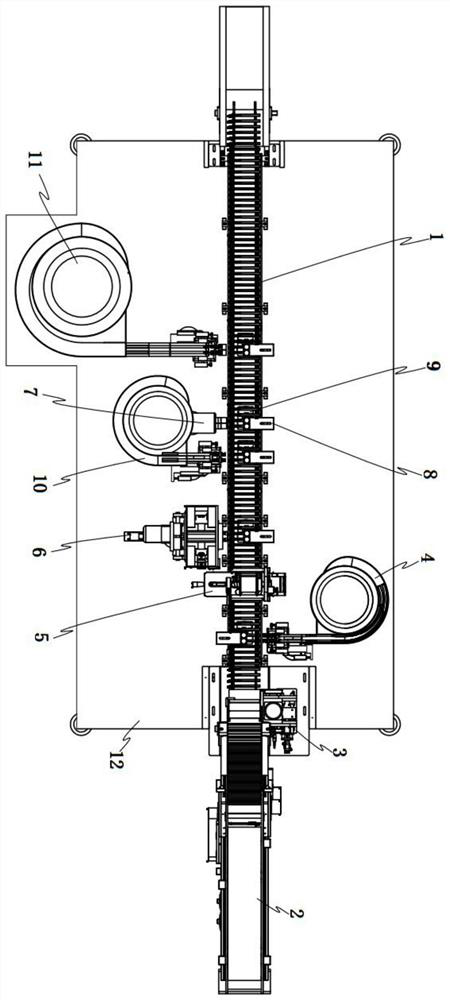

Stationery writing pen assembling machine

A stationery book and assembly machine technology, which is applied in the repair and printing of writing utensils and ink pens, can solve the problems of low production efficiency, high labor cost, and great influence on the proficiency of production work efficiency, and achieve stable quality and improved Production efficiency, the effect of reducing labor cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

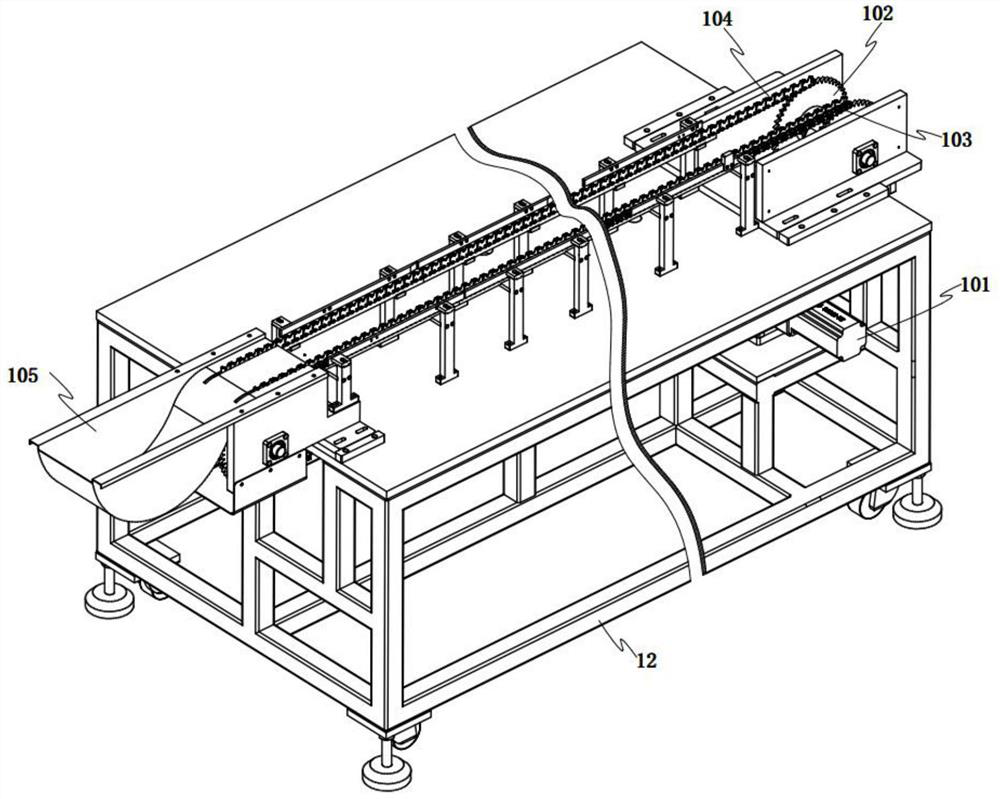

Embodiment 1

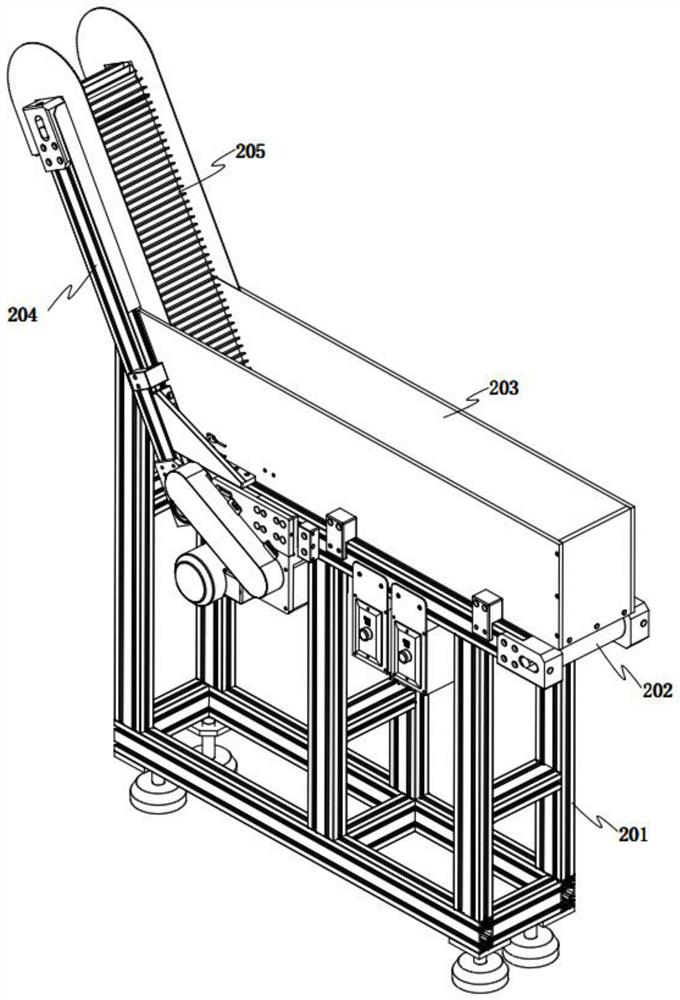

[0040]When this assembly machine is working, the pen tube in the pen tube storage frame groove 203 is transported to the lower end of the inclined upward output belt 204 by the horizontal conveyor belt 202 of the pen tube storage and conveying mechanism 2, and the inclined upward output belt 204 is in operation at the same time. , the pen tubes fall into the partition groove 205, and the pen tubes are transported upwards one by one, and finally roll down into the pen tube introduction mechanism 3 under the action of gravity, and then the pen tubes are moved along the movable introduction seat 307 of the pen tube introduction mechanism 3. The guide piece 308 rolls in from top to bottom, and at the same time, the displacement drive motor 306 drives the sliding guide rod II 310 to slide on the mounting seat 301 through the eccentric pull rod 311, thereby adjusting the position of the output slot 309, so that the pen tube moves from the guide piece The output slit 309 at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com