A rail chassis wheel hub motor

A hub motor and chassis technology, which is applied to the transmission device, electromechanical device, and electrical components driven by an electric motor, can solve the problems of increased load on the hub motor, burnout of the hub motor, and difficult heat dissipation requirements of the air-cooled heat dissipation system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

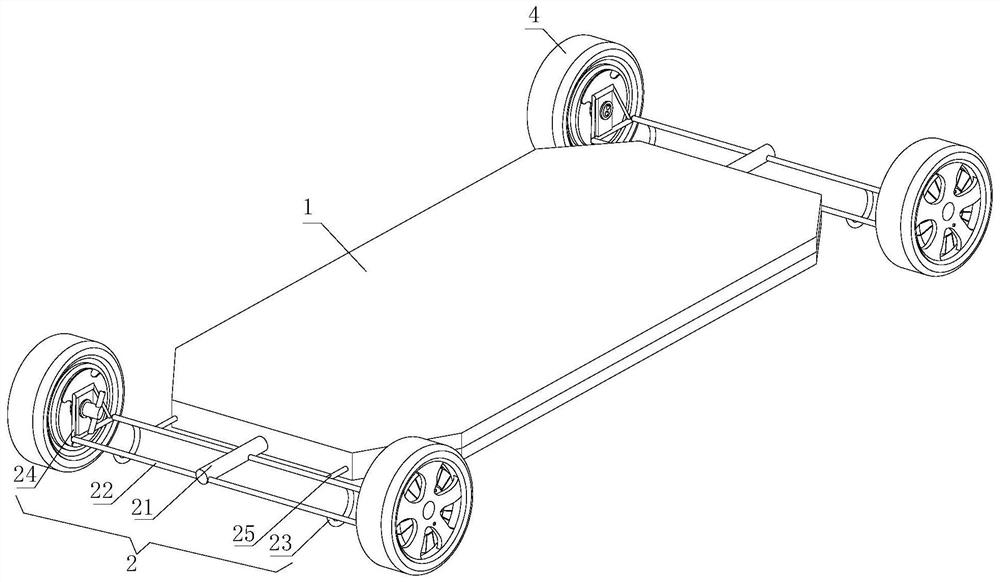

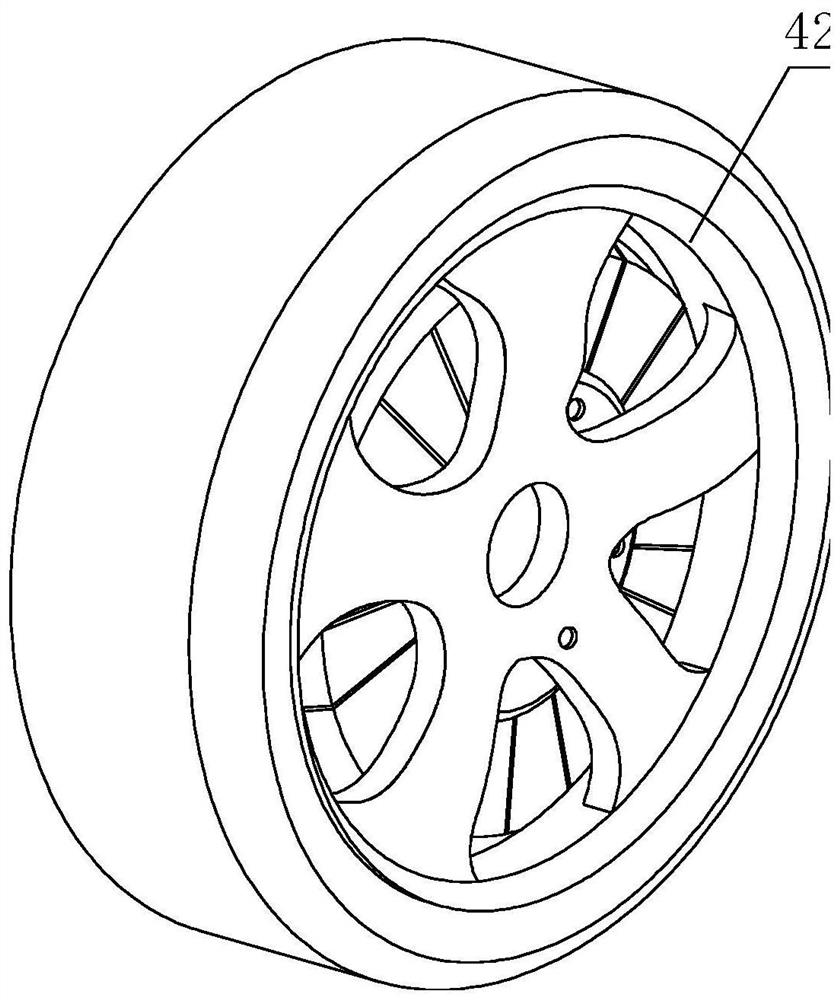

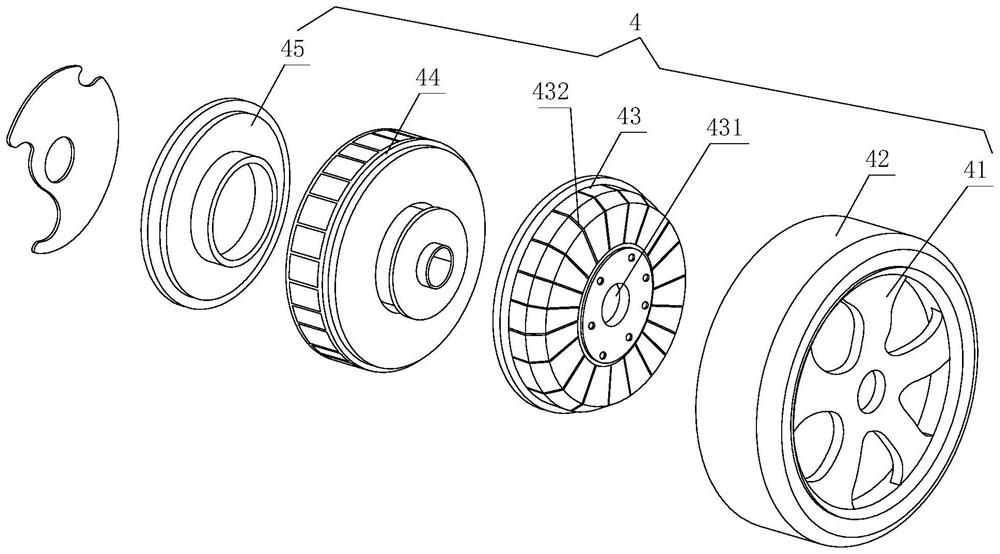

[0032] see figure 1 , a rail chassis wheel hub motor, including a chassis 1 and a frame 2, the frame 2 is installed on the front and rear sides of the chassis 1, the frame 2 serves as a buffer and support function, and its hardness is adjusted according to the use of the rail chassis. The rigidity of the chassis makes it more comfortable for the matcher, and the frame 2 also has a certain shock absorption function. The suspension 3 is connected to the fixed in-wheel motor. The function of the suspension 3 is to transmit the force and torque acting between the in-wheel motor assembly 4 and the frame 2, and use the buffer to transmit the uneven road to the frame 2 or To reduce the impact force of the chassis 1 and reduce the vibration caused thereby, the suspension 3 is connected to the in-wheel motor assembly 4 and the cooling device 5, and the cooling device 5 extends to the in-wheel motor assembly 4 to reduce the temperature.

[0033]The frame 2 includes a main beam 21, an a...

Embodiment 2

[0043] The structure of the cooling device 5 is changed, and the rest is the same as the first embodiment. The cooling device 5 includes a sleeve seat 51, a shaft rod 52, a liquid inlet pipe 53 and a liquid outlet pipe 54. On both sides of the sleeve seat 51, the liquid inlet pipe 53 and the liquid outlet pipe 54 are located on the radial direction of the two sides, and the diameters of the two nozzles are the same. The liquid inlet pipe 53 is connected with the output end of the refrigeration component, and the liquid outlet pipe 54 is connected to the input end of the refrigeration assembly. When the refrigeration assembly is working, the temperature of the cooling liquid is lowered and flows into the liquid inlet pipe 53. The liquid outlet pipe 54 flows the cooling liquid that exchanges superheat, and flows into the refrigeration assembly to re-refrigerate to complete The continuous circulation of the cooling liquid achieves the function of continuously dissipating heat to t...

Embodiment 3

[0046] Change the structure of the cooling device 5, and the rest is the same as the first embodiment. On both sides, and the diameter of the nozzles of both are the same, the liquid inlet pipe 53 is connected to the output end of the refrigeration component, and the liquid outlet pipe 54 is connected to the input end of the refrigeration component. In the liquid pipe 53 and the liquid outlet pipe 54, the cooling liquid that exchanges superheat flows, and flows into the refrigeration component, and re-refrigerates to complete the continuous circulation of the cooling liquid, thereby realizing the function of continuously dissipating heat to the inside of the hub motor assembly 4. , the liquid inlet pipe 53 and the liquid outlet pipe 54 are combined with the shaft rod 52, the two ends of the cooling channel 521 are respectively connected with the liquid inlet pipe 53 and the liquid outlet pipe 54, and the structure of the sleeve seat 51 is removed, and the shaft is directly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com