Hull clamping and lifting equipment used for shipbuilding

A hull and equipment technology, applied in the field of clamping and lifting equipment for shipbuilding hulls, can solve problems such as poor control and determination of azimuth relationship, and achieve the effects of easy lifting, good azimuth control effect, and increased lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

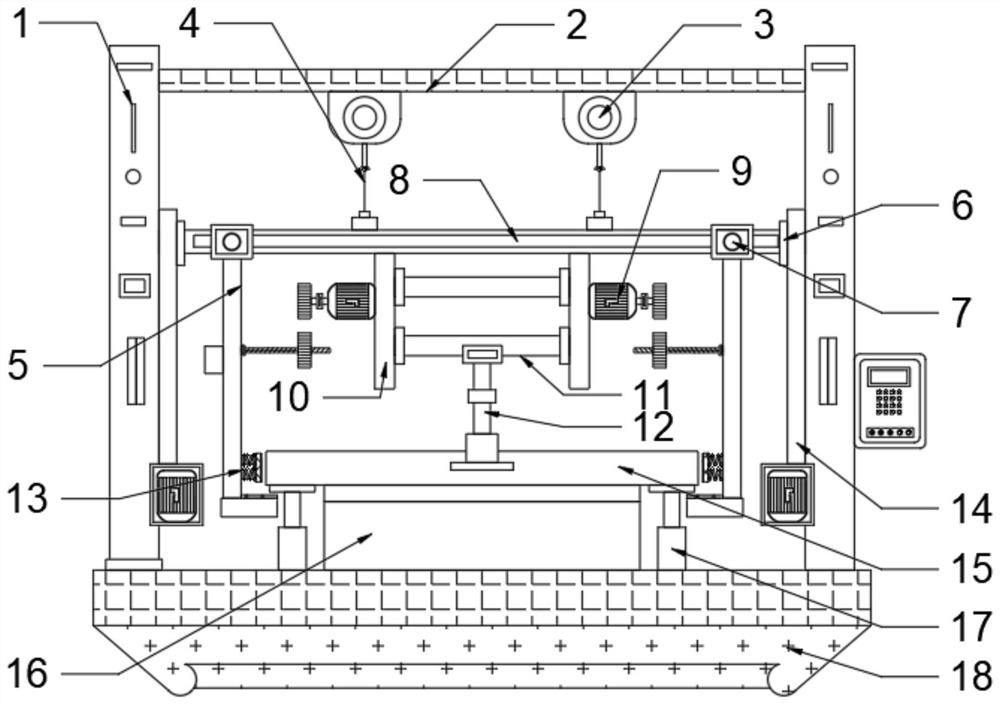

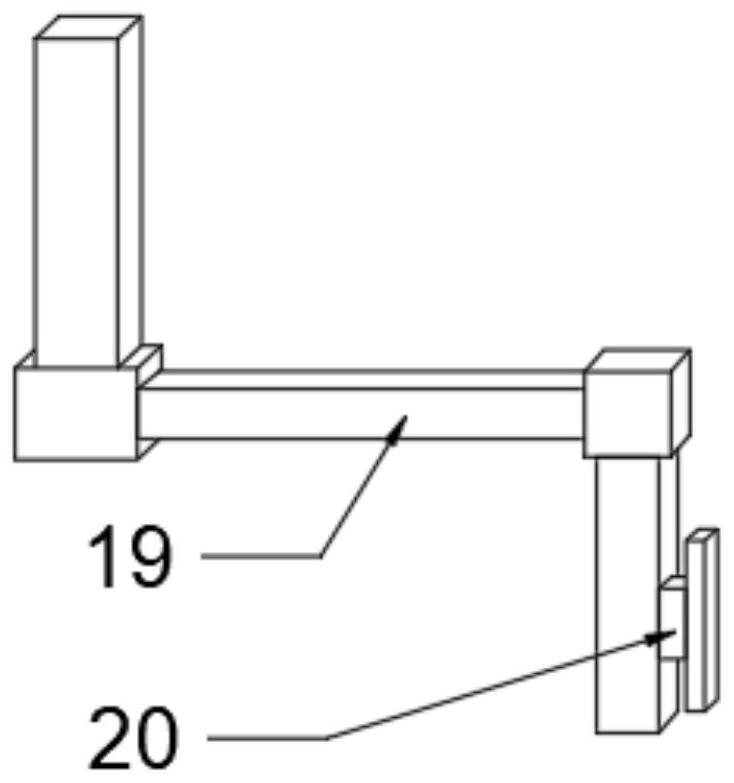

[0020] see Figure 1~2 , in an embodiment of the present invention, a shipbuilding hull clamping and lifting equipment includes a mounting frame 1; the mounting frame 1 is installed on the top of the base 18; the top of the base 18 is provided with a workbench 16; the mounting frame 1 and a top seat 2 is installed between them; the corresponding hull 15 of the installation frame 1 is provided with a lifting mechanism.

[0021] Further, the lifting mechanism includes a lifting splint 5; the bottom end of the lifting splint 5 is provided with a bottom placement plate; the top end of the lifting splint 5 is provided with a fixing sleeve; the fixing sleeve is sleeved on the adjusting installation rod 6; The fixing sleeve is provided with a fixer 7; the fixer 7 includes an electromagnetic box; the inside of the electromagnetic box is provided with an electromagnet; the electromagnet is connected to the iron sheet through a pressure spring; the iron sheet is far away from one end of...

Embodiment 2

[0027] see figure 1 , the top of the base 18 is equipped with a hydraulic rod 17; the top of the hydraulic rod 17 is provided with a top plate; the top of the top plate is in contact with the hull 15; the hull 15 is in contact with one side of the buffer fixer 13; The other side of the device 13 is fixedly connected to one side of the lifting splint 5; the buffer fixer 13 includes a buffer spring; one end of the buffer spring is fixedly connected to the lifting splint 5; the other end of the buffer spring is fixedly connected to the buffer plate; The buffer fixer 13 limits the left and right positions of the hull 15; the hydraulic rod 17 reduces the bearing pressure of the hoisting mechanism when the hull 15 is lifted, and increases the hoisting speed.

[0028] The working principle of the present invention is: through the setting of fixed plate 10, slide rail 8, fixed sleeve and fixer 7, can adjust the clamping and fixing of lifting splint 5 to hull 15, and the placement and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com