Electrical equipment precise installation intelligent operation platform

A technology of intelligent operation and electrical equipment, applied in the direction of lifting equipment safety device, lifting device, etc., can solve the problems that the operating platform cannot be self-locked, the supporting feet can be manually pulled out manually, etc. The effect of preventing overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

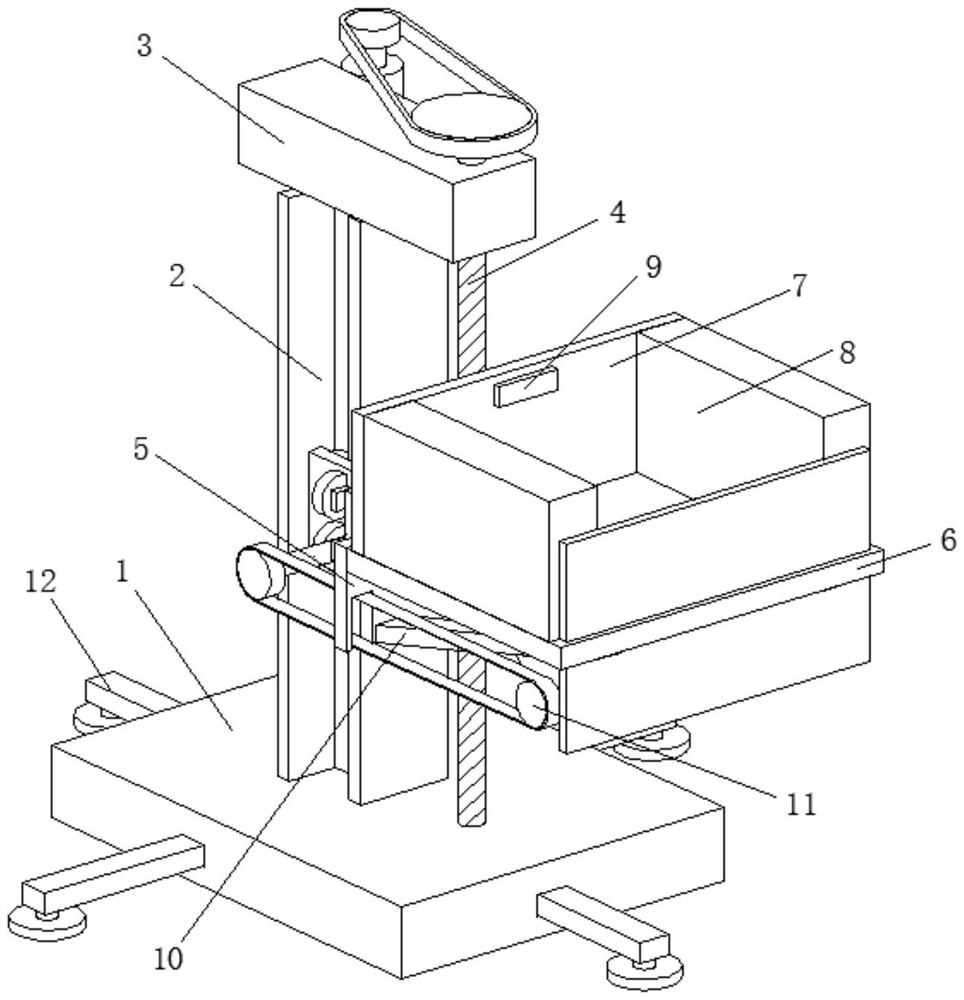

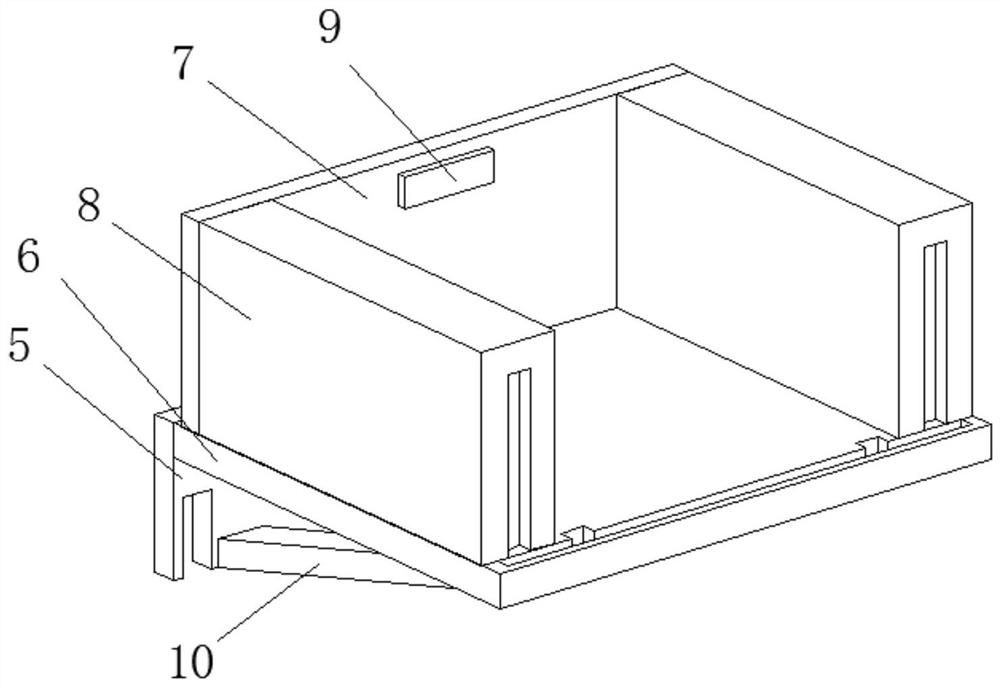

[0034] An intelligent operation platform for precise installation of electrical equipment, such as Figure 1-Figure 6 As shown, including the base 1, the top of the base 1 is welded with an I-beam 2, the top of the I-beam 2 is welded with a mounting block 3, the bottom of the mounting block 3 is provided with a lifting mechanism 4, and the right side of the lifting mechanism 4 is set There is connecting plate 5, and the right side of connecting plate 5 is welded with supporting plate 6, and the top of supporting plate 6 is welded with baffle plate 7 and toolbox 8 respectively, and toolbox 8 is positioned at the right side of baffle plate 7, and the right side of baffle plate 7 The side is connected with a control panel 9 by bolts, a support rod 10 is welded between the connection plate 5 and the support plate 6 , the lower surface of the support rod 10 is provided with a protection mechanism 11 , and the inside of the base 1 is provided with a support mechanism 12 .

[0035] I...

Embodiment 2

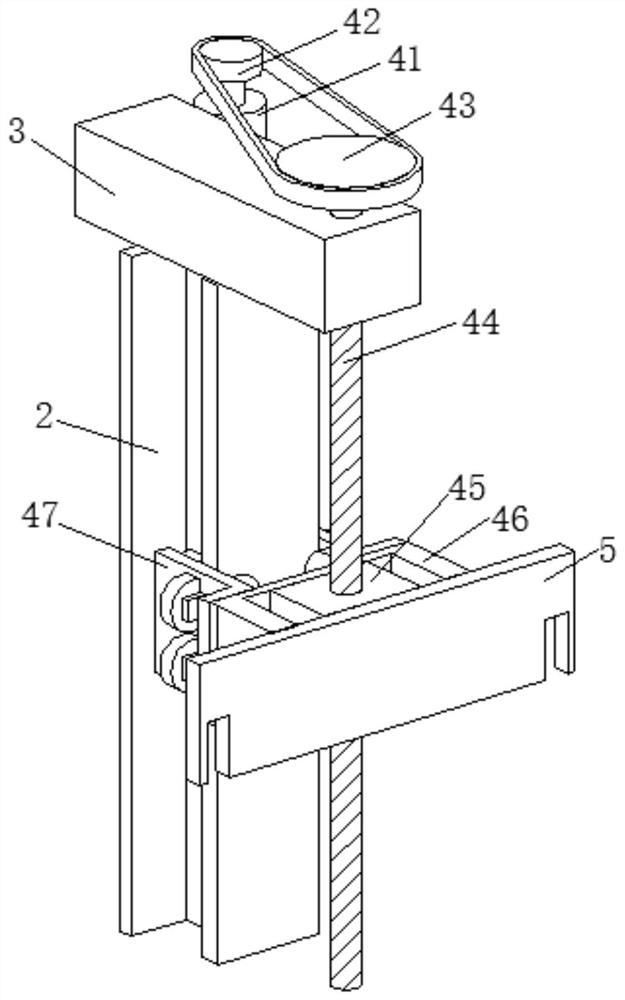

[0041] Such as Figure 5-Figure 8 As shown, the rear portion of the rotating shaft 111 is clamped and fixed with the axial center of the second roller 472, the surface of the rotating shaft 111 is rotationally connected with the inner wall of the moving plate 47, and the axial center of the second sprocket 113 and the transmission gear 116 are respectively connected with the support The front part and the rear part of block 114 are rotatably connected, the surface of transmission gear 116 and the surface of teeth 117 are meshed with each other, and rotating shaft 111 is connected with the No. The protective mechanism 11 drives the protective fence 115 to rise, and when the second roller 472 descends, the protective fence 115 also descends. When the rotating shaft 111 is connected with the second roller 472 on the left side, the second roller 472 rises and the protective fence 115 will descend, resulting in Cannot play a protective role.

[0042] It is worth noting that the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com