Platinum channel installation method considering expansion characteristic and platinum channel

A platinum channel and installation method technology, applied in the direction of the feeding trough, can solve the problems of inability to guarantee, inaccurate installation process, not considering refractory materials, etc., to achieve improved welding process, accurate installation technology process, accurate and controllable expansion size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032]The embodiment of the present invention provides a platinum channel installation method and platinum channel that take into account expansion characteristics.

[0033]The installation method is as follows:

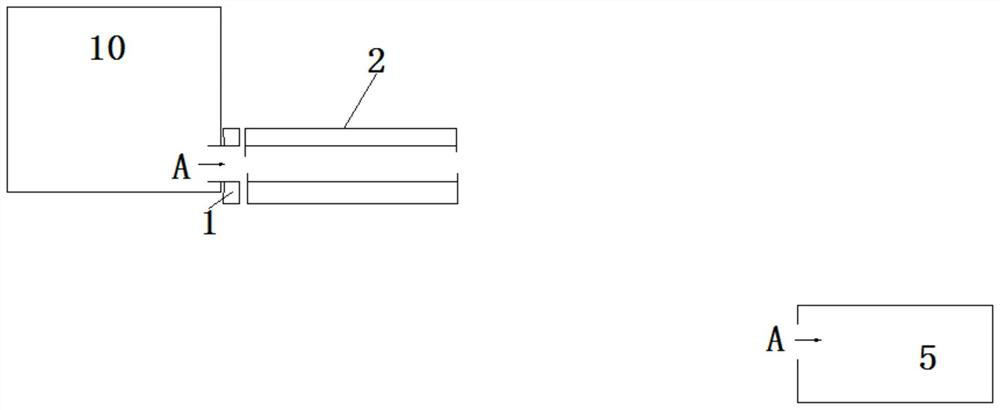

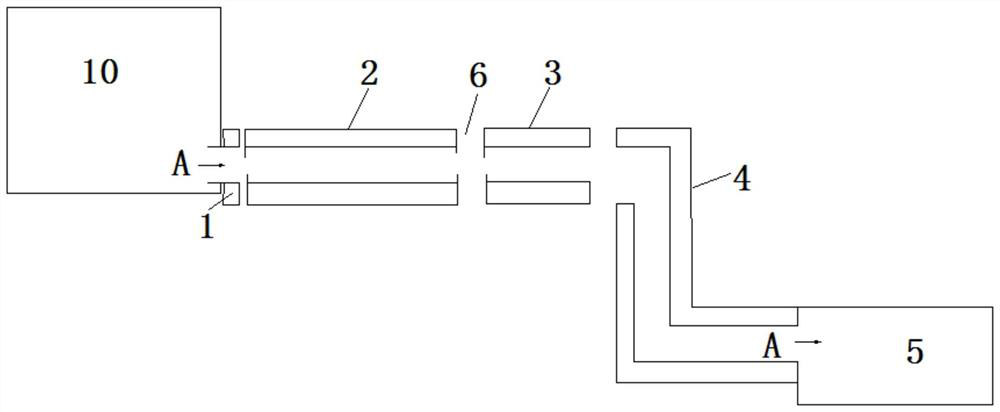

[0034]figure 1 Construction is the first step of the installation method. The throat pipe 1 is installed according to the hole position of the glass furnace 10 (the hole position where the molten glass flows out). During the installation process, the actual markings on the top, bottom, left, and right of the throat pipe 1 should be overlapped with the marking lines of the hole position of the glass furnace 10; and the throat pipe 1 should be fixed in position. The actual marking line of 1 and the actual marking line of the temperature rising clarification section 2 correspond to overlap, and the platinum body and refractory brick mixture structure of the temperature rising clarification section 2 are installed in place.

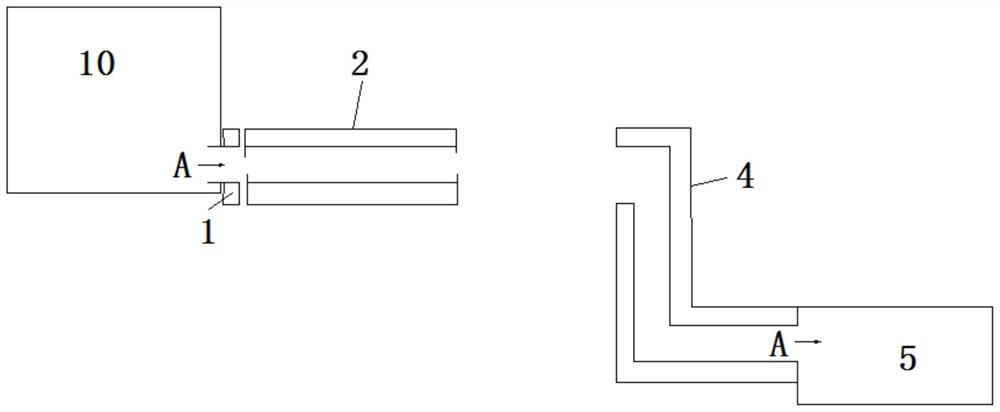

[0035]figure 2 Construction is the second step of the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com