Systems and methods for operating underground machine

A technology of control system and positioning system, applied in the direction of underground transportation, control/regulation system, radio wave measurement system, etc. level of performance and operational issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

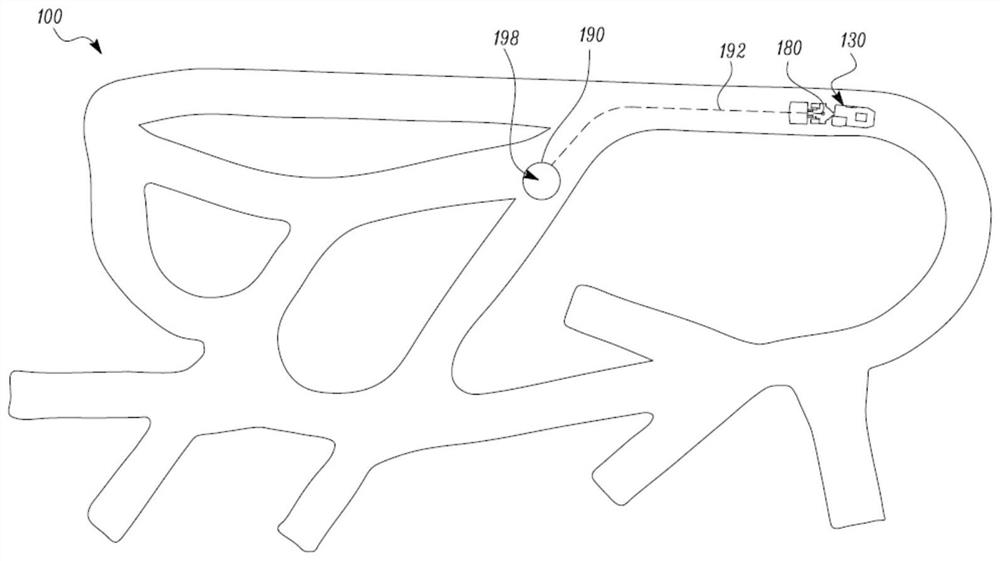

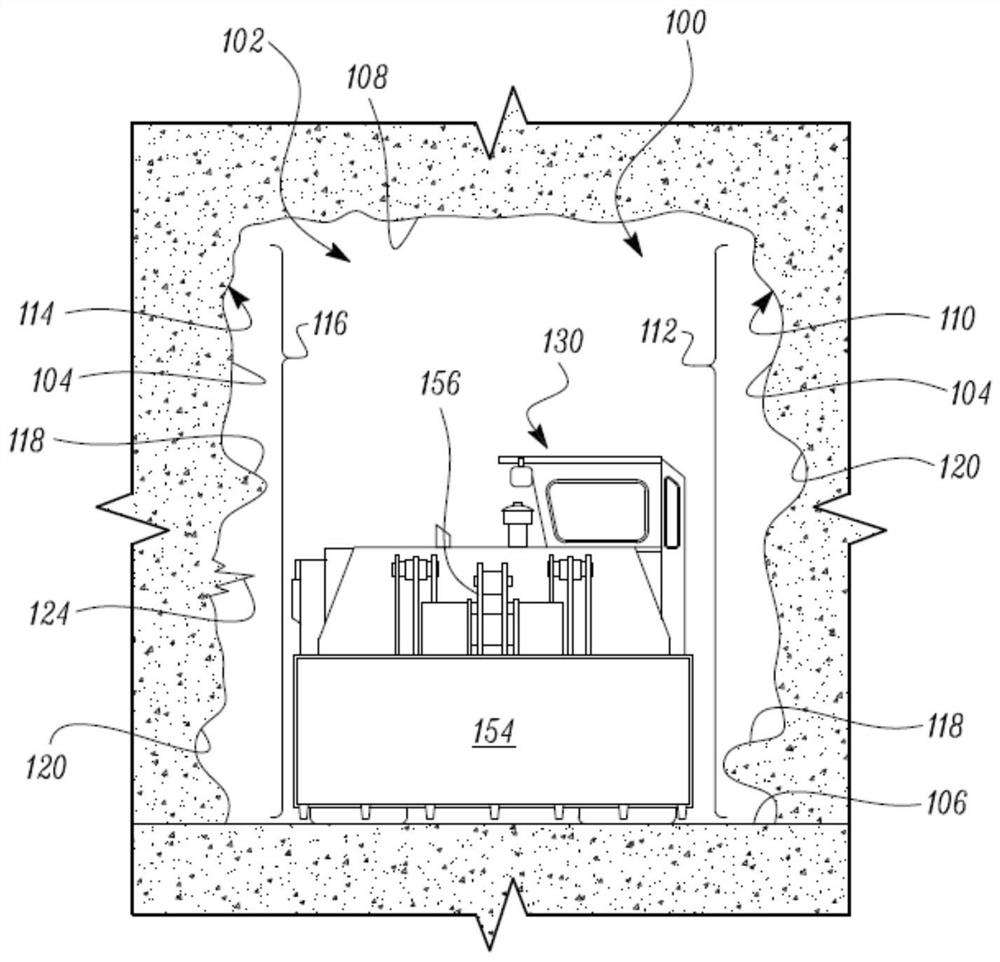

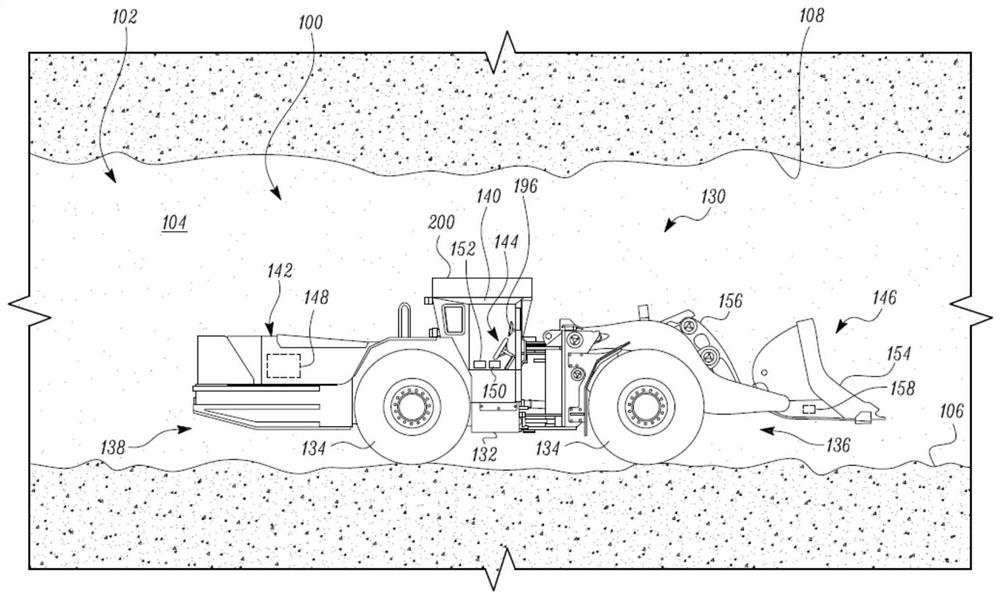

[0018] now refer to figure 1 and figure 2 , an exemplary worksite 100 is shown. Worksite 100 is illustrated in the illustration as a mining area. However, in various other embodiments, worksite 100 may embody and / or include, for example, a landfill, quarry, construction site, or any other type of worksite. refer to figure 2 , shows a front view of machine 130 operating at worksite 100 . As seen therein, worksite 100 includes terrain 102 having one or more sidewalls 104 , a floor 106 , and a ceiling 108 . Each of the one or more side walls 104, the floor 106, and the ceiling 108 may include a profile. In one embodiment, a profile may be defined as a 2D (2-dimensional) representation of geometric parameters assoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com