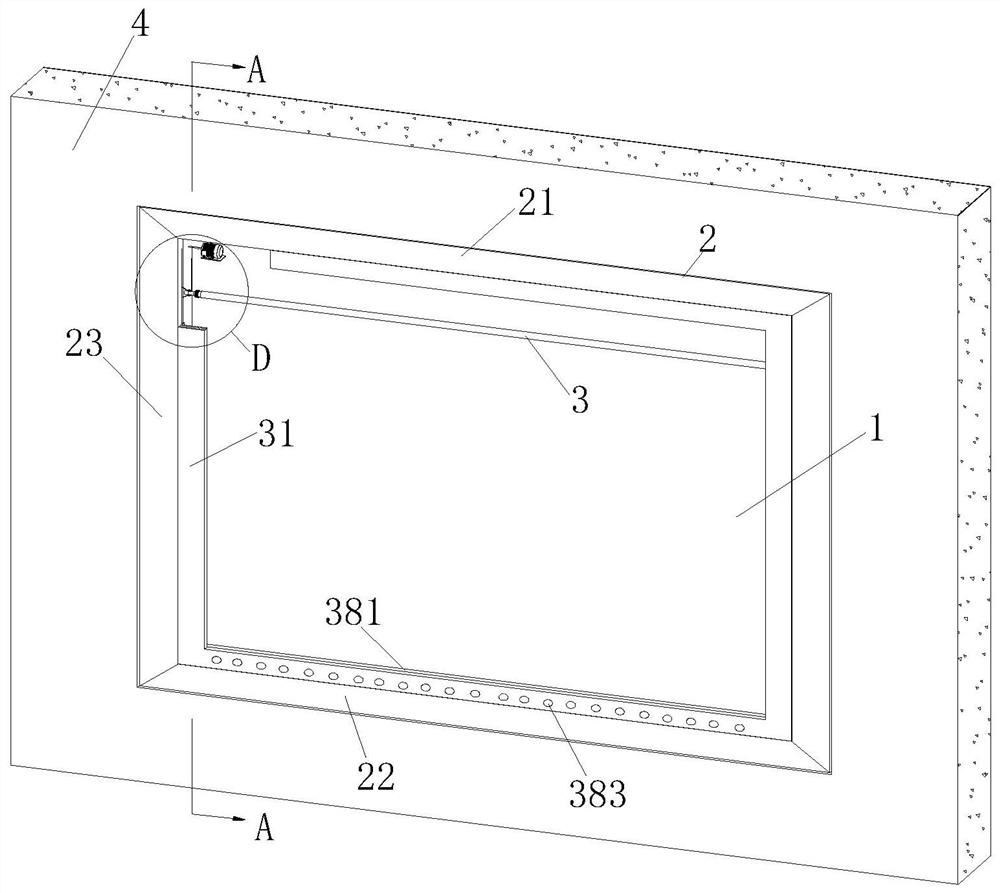

Aluminum alloy door and window with functions of high compression resistance, corrosion resistance and energy saving

A kind of aluminum alloy doors and windows, corrosion-resistant technology, used in special equipment for doors/windows, cleaning of windows/doors, windows, etc., can solve the problems of dangerous cleaning personnel, dusty, difficult to clean hollow glass, etc., to ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

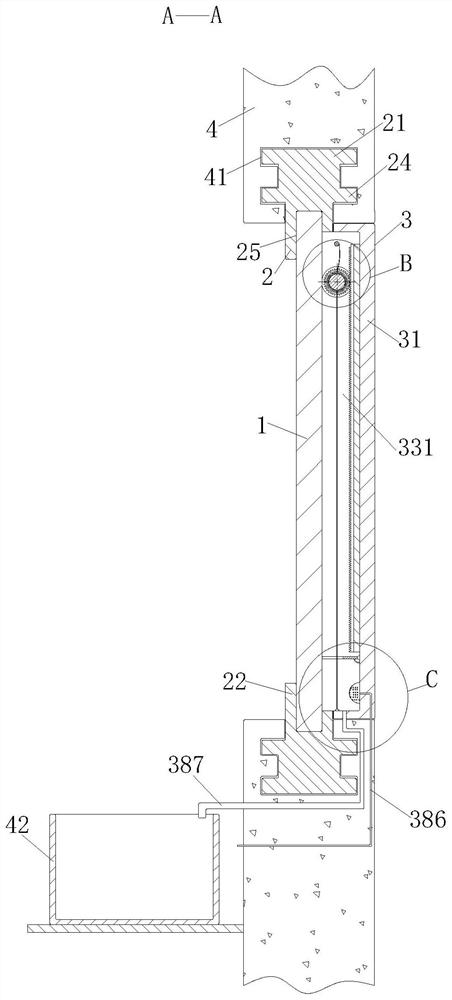

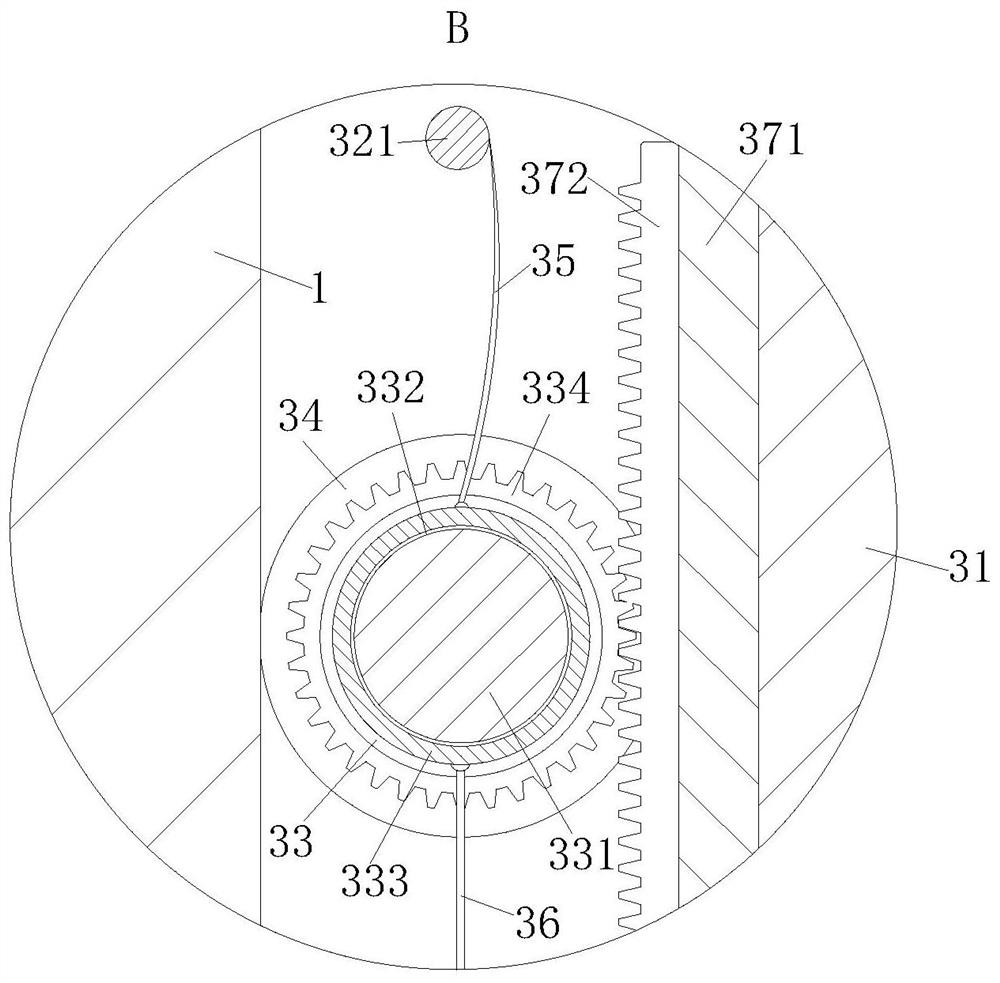

[0033] As a specific embodiment of the present invention, the position where the dust-proof plate 381 is opposite to the No. 1 elastic rope 36 is provided with a No. 3 groove 385, and the inner surface of the No. 3 groove 385 is provided with cotton cloth; through the function of the No. 3 groove 385 , so that when the dust removal cylinder 33 moves under the action of the connection rope 35, the No. 1 elastic rope 36 driven by the No. 1 shaft 331 will not affect the closing of the dustproof plate 381; After leaving the storage room 38 under the action, the No. 1 elastic rope 36 is stretched and embedded in the No. 3 groove 385, so the end of the dustproof plate 381 can be smoothly closed and contacted with the surface of the hollow glass 1 near the outside, so that the storage room The dust in 38 is limited in the storage chamber 38, and cannot be separated from the storage chamber 38 and reattached to the surface of the hollow glass 1 near the outside; in addition, the cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com