Ratchet push-pull self-locking electric connector

An electric connector, push-pull self-locking technology, applied in the direction of connection and connection device components, circuits, etc., can solve problems such as constraints, increased installation difficulty, locking and unlocking process operation complexity, etc., to achieve ingenious structure, self-locking The effect of stable performance and convenient plug-in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

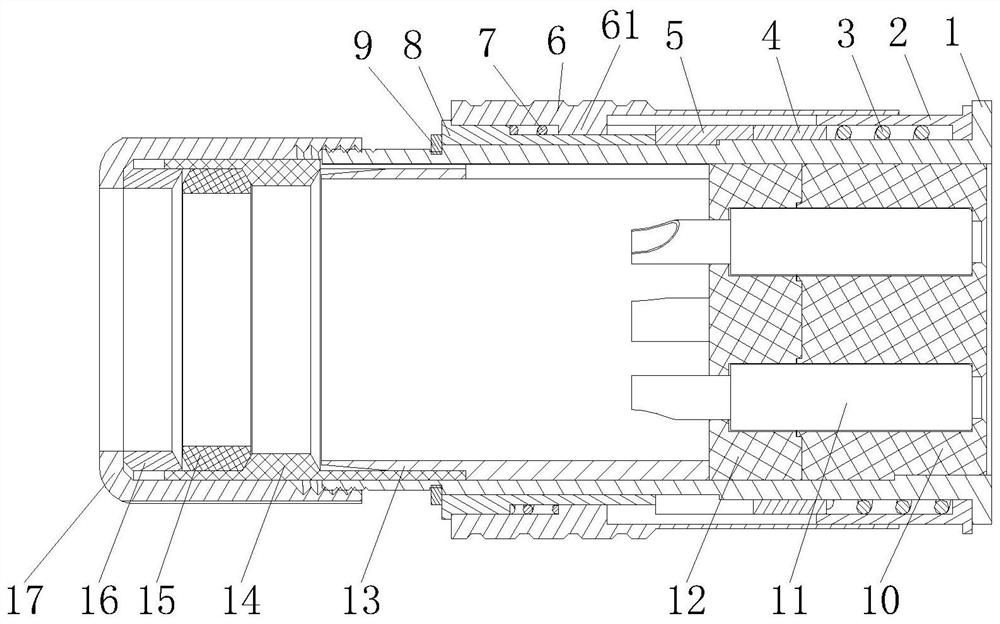

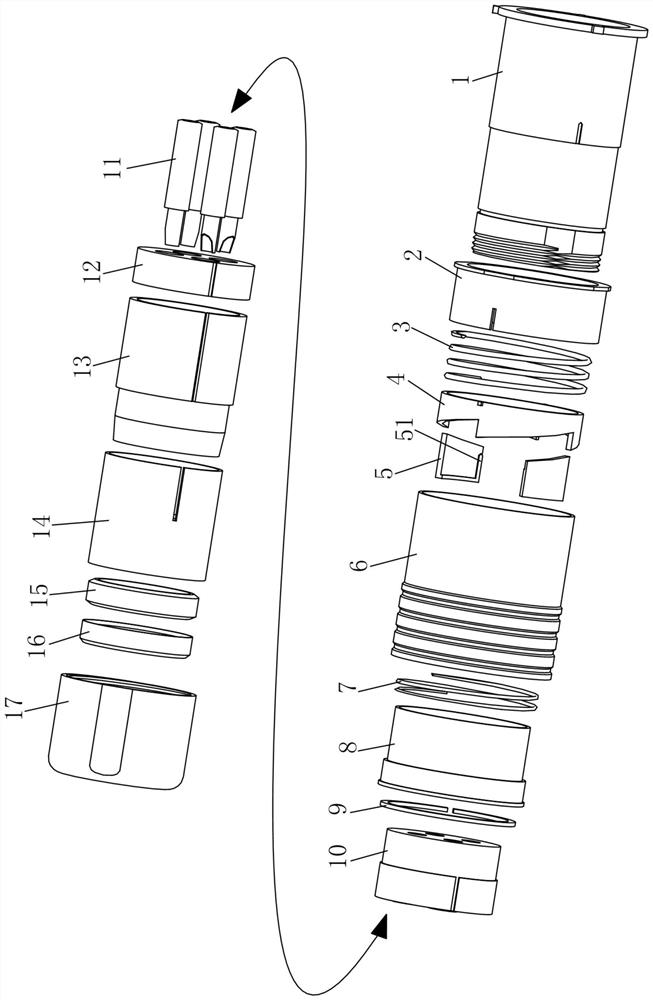

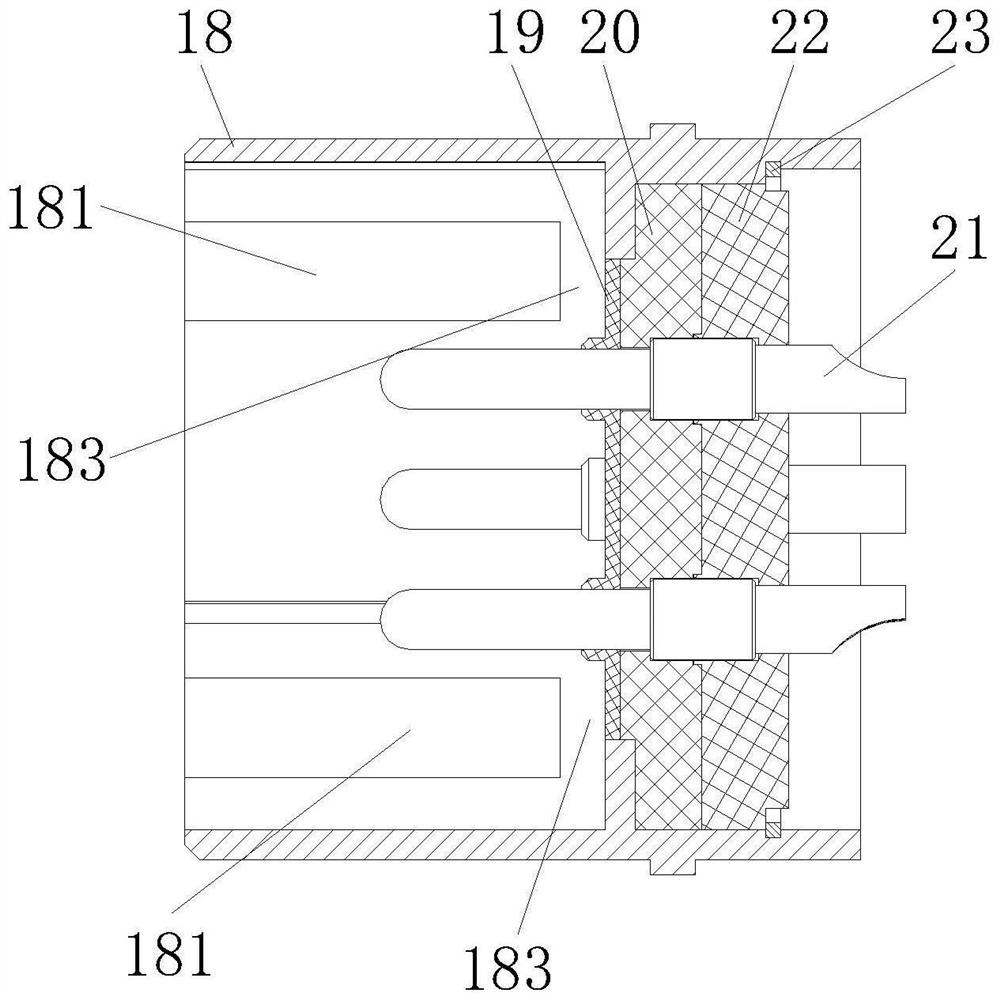

[0038] like Figure 1 to Figure 15 As shown, a ratchet push-pull self-locking electrical connector includes a plug assembly and a socket assembly. The plug assembly includes a head shell 1 and a tail nut 17 connected to the head shell 1. The front end of the head shell 1 is movably fitted with a locking ring. 2. A ratchet 4 is movably installed on the locking ring 2, and the ratchet 4 can move axially between the head housing 1 and the locking ring 2, such as figure 1 As shown, the ratchet 4 moves axially on the locking ring 2 , and at the same time the ratchet 4 can drive the locking ring 2 to rotate outside the head housing 1 . like Figure 7 , Figure 8As shown, the locking ring 2 has a limit chute A201, and the outer wall of the ratchet 4 has a limit slider A41 corresponding to the limit chute A201. When assembling, the limit slider A41 of the ratchet 4 is installed on the lock. In the limit chute A201 of the tight ring 2, when the ratchet 4 moves axially in the lock ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com