Municipal pipeline based on liquid nitrogen conveying and provided with plugging device

A plugging device and technology for municipal pipelines, applied in the direction of pipe components, mechanical equipment, sealing surface connections, etc., can solve problems such as pipeline blockage, inconvenient operation, time-consuming and manual labor, and achieve integrity and good sealing The effect of blocking operation and reducing operation complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

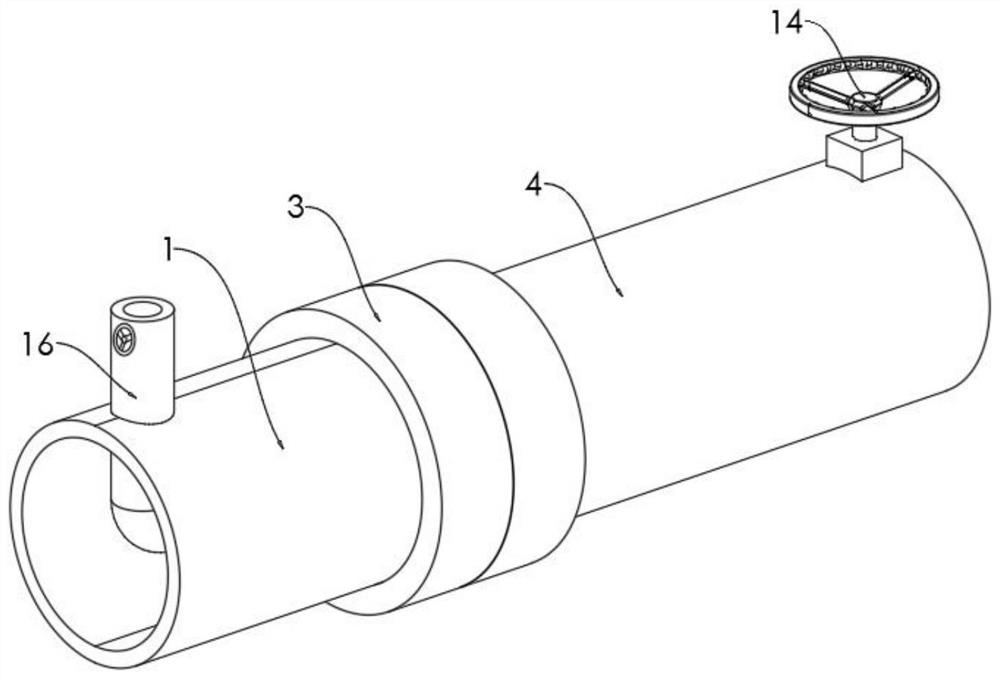

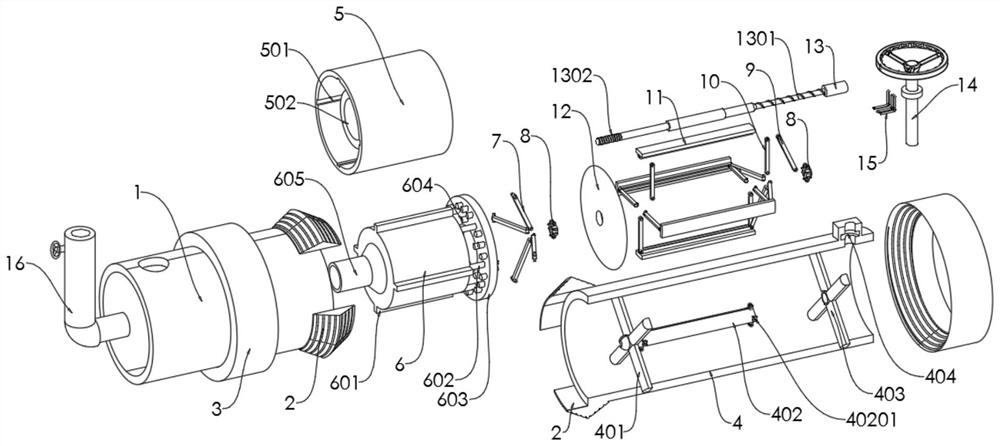

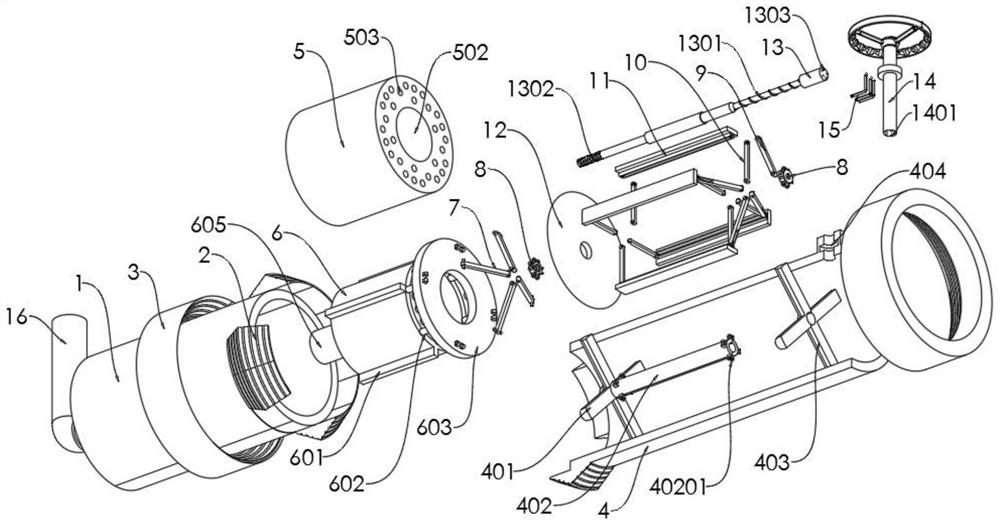

[0034] Please refer to Figure 1 to Figure 10 shown:

[0035] The present invention provides a municipal pipeline with a plugging device based on liquid nitrogen transportation, including a left connecting pipe 1, a right connecting pipe 4 is connected to the right end of the left connecting pipe 1, and a threaded fixing sleeve is slidably connected to the outer side wall of the connection between the left connecting pipe 1 and the right connecting pipe 4. 3. A filter cartridge 5 is welded inside the left connecting pipe 1, a backwashing cartridge 6 is slidably connected to the filter cartridge 5, a connecting arm 7 is connected to the right side wall of the backwashing cartridge 6, and a control rod 13 is rotatably connected to the middle of the right connecting pipe 4. , the left and right ends of the control rod 13 are threadedly connected with the control seat 8, the control seat 8 is connected with the pull rod 10 and the right end of the side wall support plate 11 throug...

Embodiment 2

[0039] A fixed bracket 401 and a limit frame 403 are respectively arranged in the inner cavity of the left and right side of the right pipe 4. The fixed bracket 401 and the limit frame 403 are both cross-shaped, and the left and right ends of the control rod 13 are rotatably connected to the fixed bracket 401 and the limit frame. In the middle of the position frame 403, the middle of the right side wall of the fixed bracket 401 is connected with a support sleeve rod 402. The left and right outer side walls of the support sleeve rod 402 are provided with four connecting shaft seats 40201 in an annular array. A sealing ring groove 404 is opened in the block, and the rotating rod 14 is rotatably connected to the sealing ring groove 404.

[0040] Among them, five transmission holes 1303 are opened in the right side wall of the control rod 13, the left end of the L link 15 is inserted into the transmission holes 1303, and the outer side wall of the right end of the control rod 13 is...

Embodiment 3

[0043] The inner side wall of the filter cartridge 5 is provided with four long connecting chutes 501 in a circular array. The filter cartridge 5 is provided with a filter inner cylinder 502 in the middle of the inner cavity. The right end of the inner cylinder 502 is open, and a drain hole 503 is opened in the side wall of the right end of the filter cylinder 5 .

[0044] The outer side wall of the backwash cylinder 6 is provided with four connecting sliders 601 in an annular array. The six connecting cylinders 602 of the array are connected with the water blocking baffle 603, the water blocking baffle 603 is slidably connected to the outer side wall of the right side of the filter cartridge 5, and the water blocking plug 604 on the left side wall of the water blocking baffle 603 is plugged in. In the drain hole 503 on the right side wall of the filter cartridge 5 , a water outlet 605 is provided in the middle of the left side wall of the backwash cylinder 6 , and the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com