Wood stick paint dyeing equipment for furniture

A technology of wooden sticks and furniture, applied in the direction of spraying devices, etc., can solve the problem of excess paint that is difficult to clean up, and achieve the effect of convenient dyeing of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

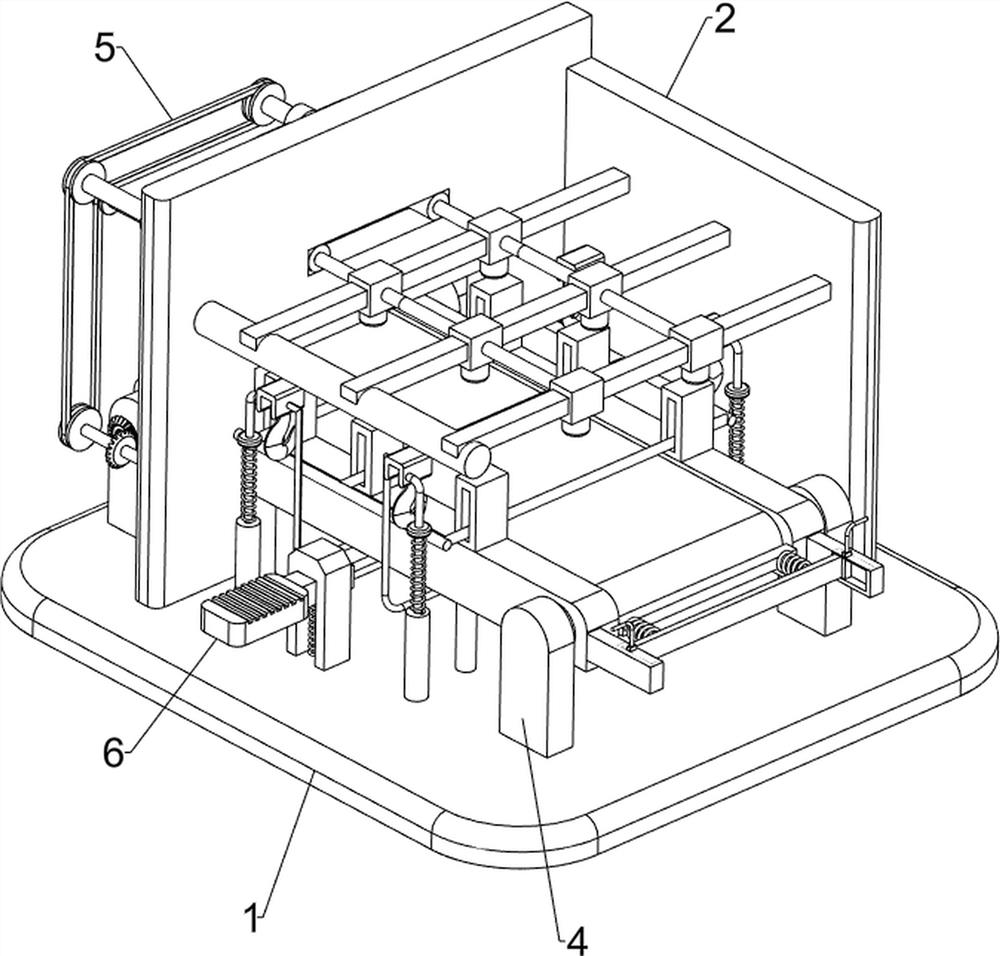

[0024] A wooden stick dyeing equipment for furniture, such as figure 1 As shown, it includes a base plate 1, a support plate 2, a servo motor 3, a transmission mechanism 4, a paint spraying mechanism 5, and a material retaining mechanism 6. There is a servo motor 3, a transmission mechanism 4 is provided on the top right side of the bottom plate 1, the parts of the transmission mechanism 4 pass through the support plate 2, and the parts of the transmission mechanism 4 are connected with the output shaft of the servo motor 3, and a paint spraying mechanism is installed on the left side of the top of the bottom plate 1 5. Parts of the painting mechanism 5 are connected to the support plate 2 , and the middle side of the top of the bottom plate 1 is provided with a stopper mechanism 6 , and the parts of the stopper mechanism 6 are connected to the parts of the transmission mechanism 4 .

[0025] When people need to dye sticks, people first place the sticks on the top of the parts...

Embodiment 2

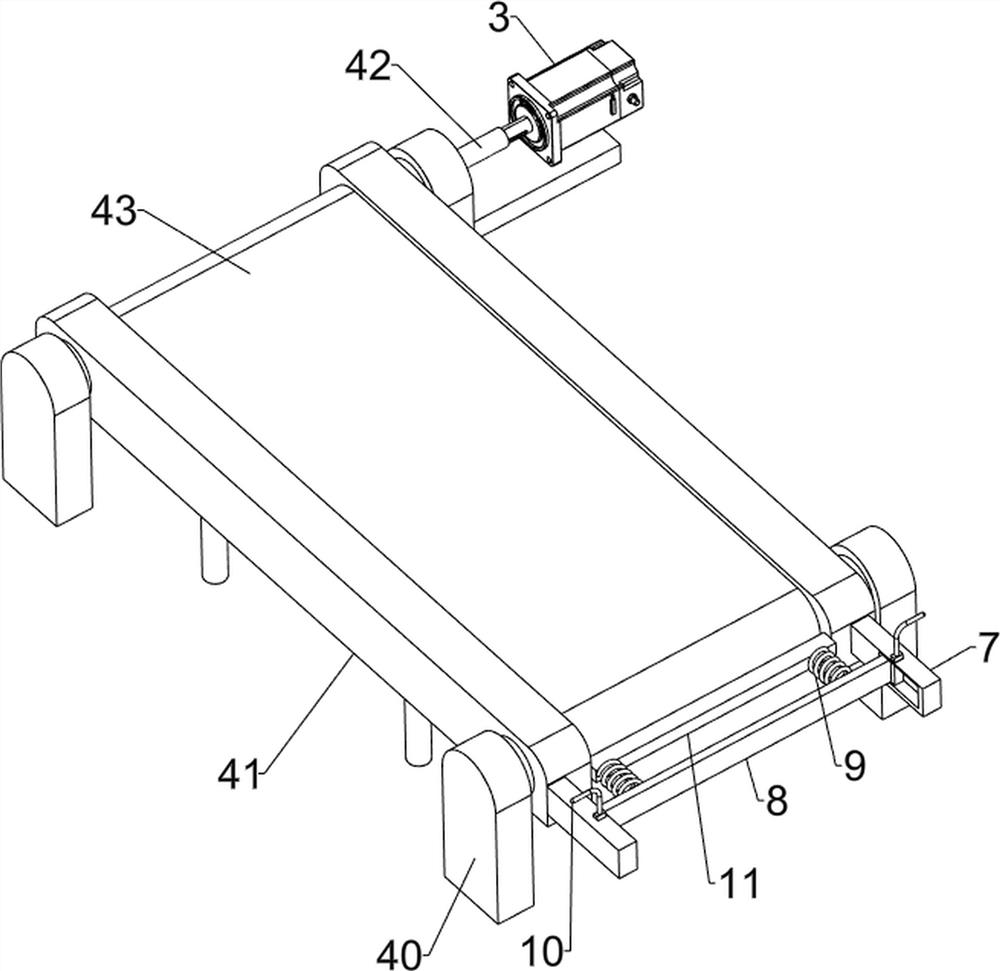

[0027] On the basis of Example 1, such as figure 2 , Figure 4 , Figure 5 with Image 6 As shown, the transmission mechanism 4 includes a mounting seat 40, a connecting plate 41, a rotating shaft 42 and a transmission belt 43. The bottom plate 1 top, front, rear, left, and right sides are all provided with mounting seats 40, between the left mounting seats 40 and the right mounting seats 40 Rotating shafts 42 are connected between them, and the left rotating shaft 42 is connected with the output shaft of the servo motor 3, and connecting plates 41 are connected in a rotating manner between the front sides of the rotating shafts 42 and the rear sides of the rotating shafts 42, and the connecting plates 41 pass through A transmission belt 43 is wound between the left side of the support plate 2 and the middle side of the rotating shaft 42 .

[0028] When people need to transport the sticks, they first place the sticks on the top right side of the transmission belt 43, and w...

Embodiment 3

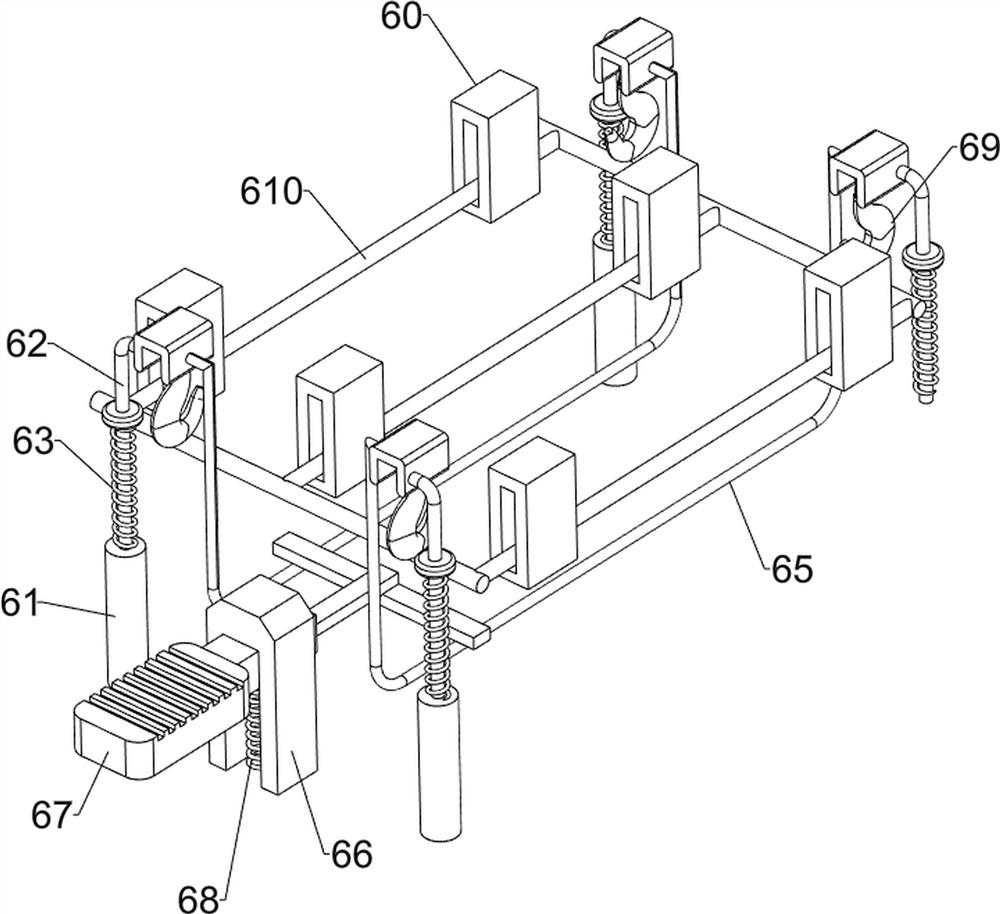

[0032] On the basis of Example 2, such as figure 2 , image 3 with Figure 7 As shown, the blocking mechanism 6 includes a sliding sleeve 60, a sliding cylinder 61, a sliding rod 62, a first spring 63, a mounting block 64, a connecting rod 65, a guide rail 66, a pedal 67, a second spring 68, a pull hook 69 and a stop frame 610, the top of the connecting plate 41 is evenly provided with sliding sleeves 60, the number of sliding sleeves 60 is 6, the middle part of the base plate 1 is provided with sliding cylinders 61 on the front, rear, left, and right sides, and the sliding cylinders 61 are all slidably connected with sliding rods 62. The first spring 63 is all connected between the upper side of the 62 and the top of the sliding tube 61, and the first spring 63 is sleeved on the slide bar 62, and the top of the slide bar 62 is provided with a mounting block 64, and between the left mounting block 64 and the right Connecting rods 65 are connected between the side mounting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com