180-degree bidirectional differential milling head

A technology of milling head and milling cutter, which is applied in the field of milling and can solve problems such as inability to achieve efficient machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

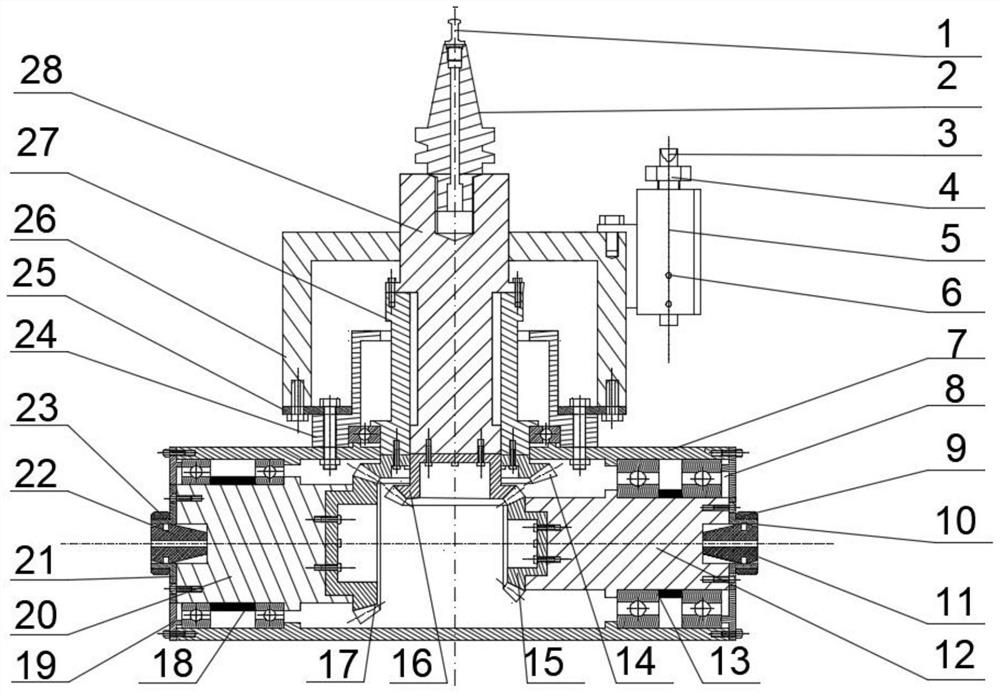

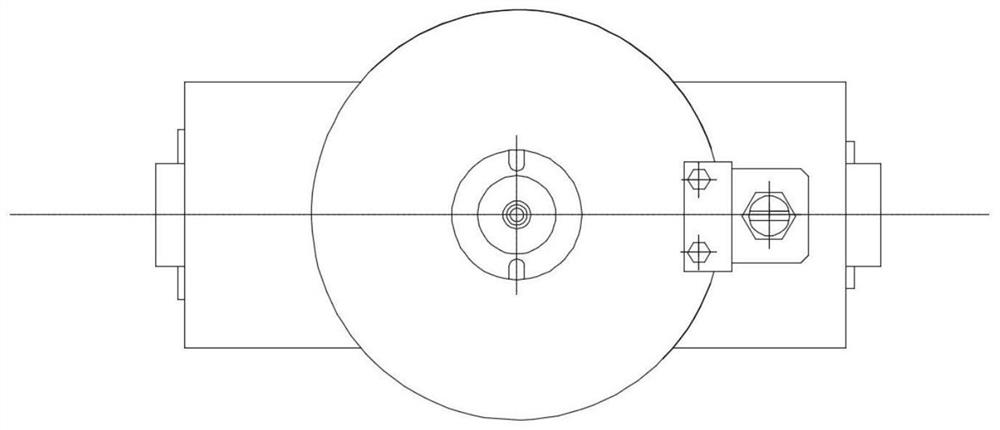

[0024] see figure 1 , figure 2 , a 180° two-way differential milling head, comprising a milling cutter housing, an outer housing, and a connecting housing arranged between the milling cutter housing and the outer housing, the milling cutter housing is connected to the connecting housing through the housing end cover The body and the outer shell are fixed by bolts. The milling cutter housing is in the shape of a straight cylinder, and the milling cutter housing is provided with a C-axis drive spindle in the axial direction. The input end of the C-axis drive spindle extends outward from the milling cutter housing and connects to the handle. The handle is 2BT40 handle. The output end of the C-axis transmission main shaft is supported on the connection housing through bearings. One side of the milling cutter housing is fixed with a positioning pin housing, and a positioning pin is slid in the axial direction of the positioning pin housing, and an organic rice screw is threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com