Novel efficient stacking machine

A stacking and high-efficiency technology, applied in the field of new high-efficiency stackers, can solve the problems of low buffer capacity, low stacking efficiency, complex structure, etc., and achieve the effect of ensuring operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

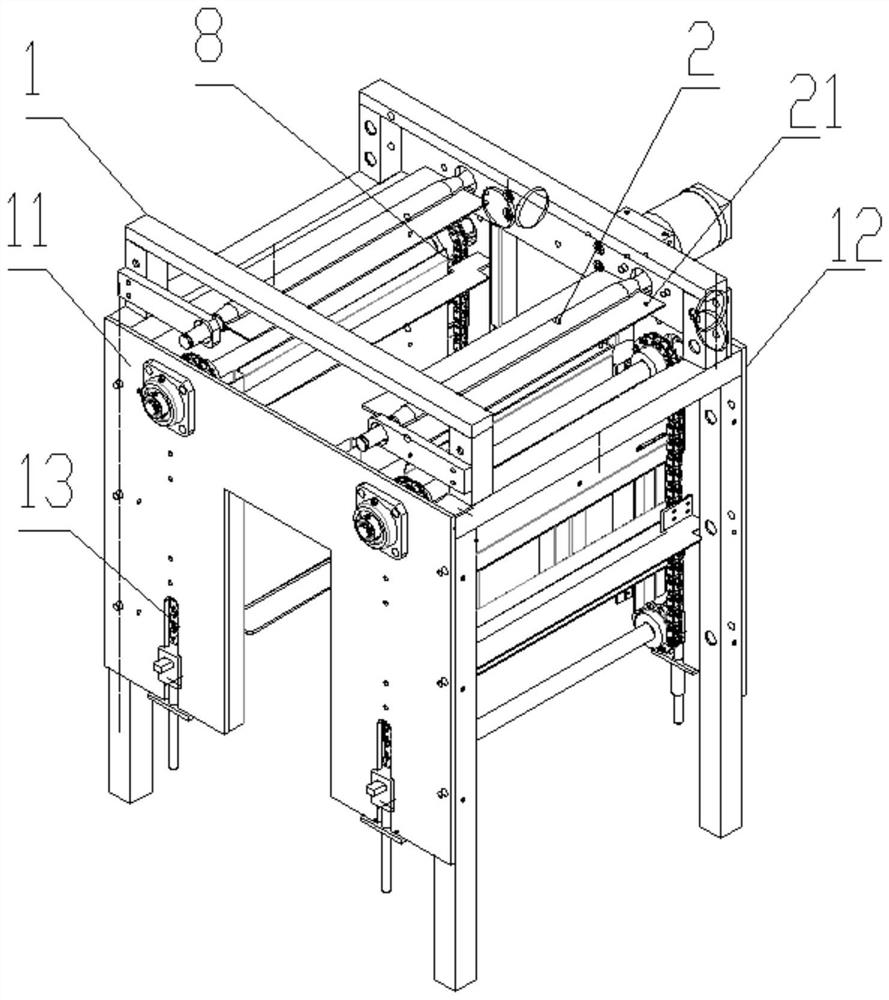

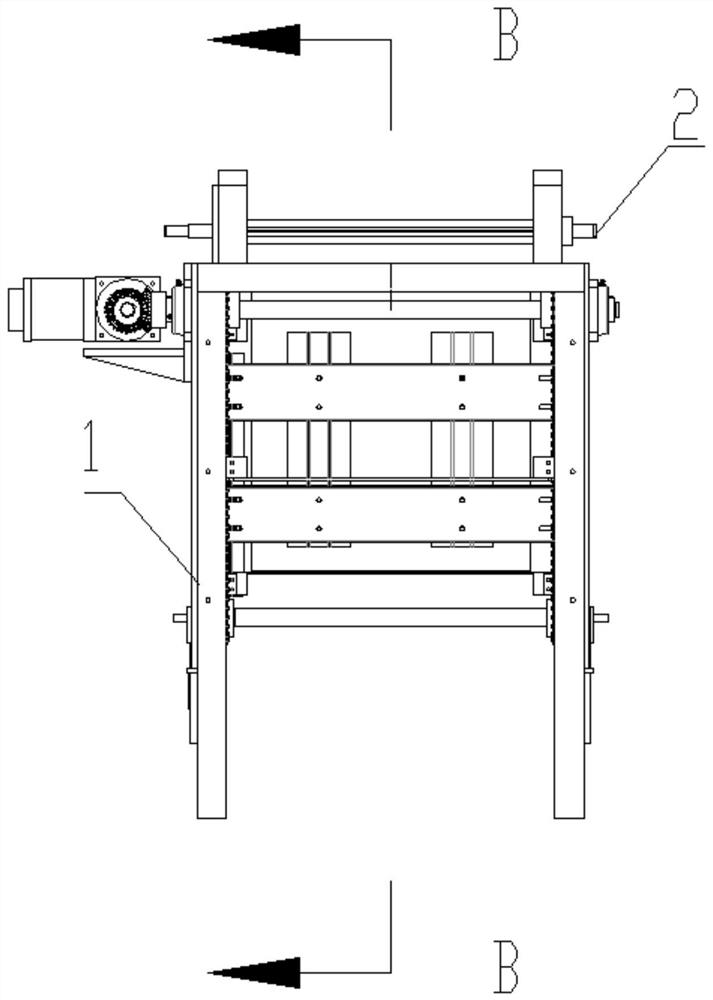

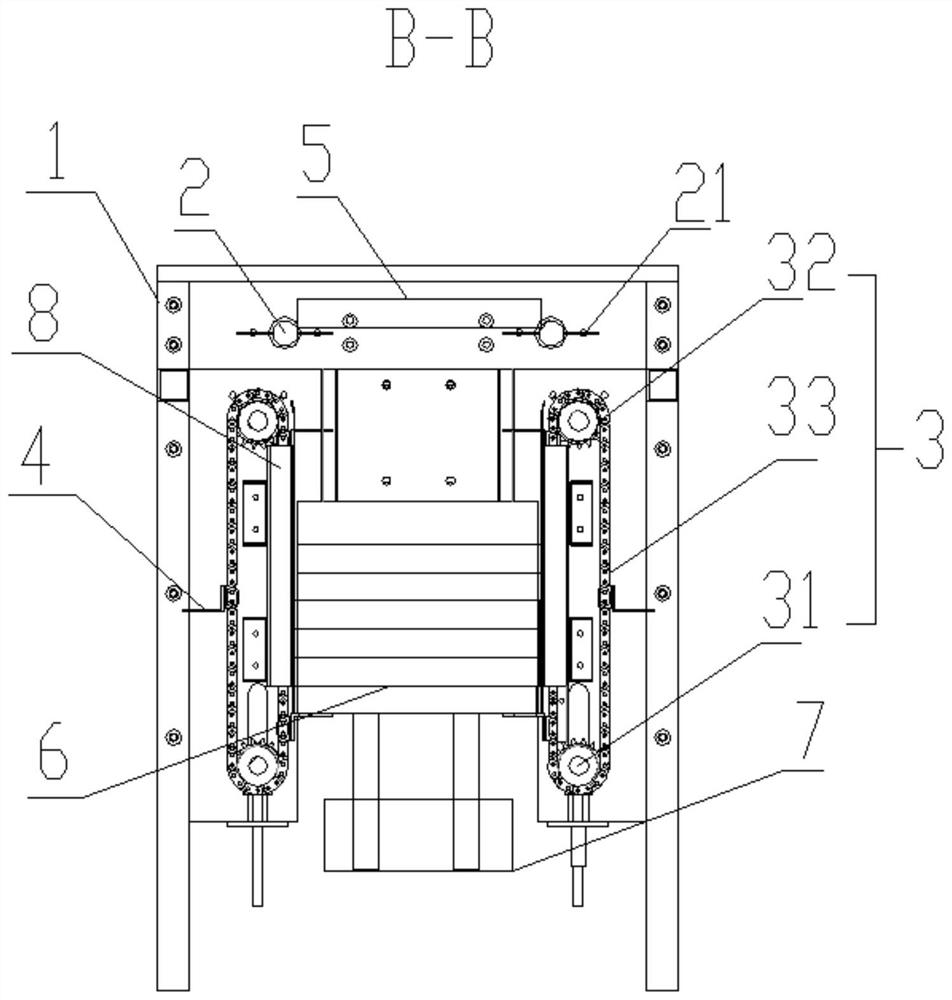

[0041] Such as Figure 1~3 As shown, in this embodiment, preferably, there are two turning shafts 2, and the two turning shafts 2 and the turning support plates 21 fixed thereon are arranged symmetrically in the horizontal direction, and the symmetrical axis is the center line of the stacker The two turning shafts 2 rotate in opposite directions, and the article 5 is located between the two turning shafts 2, and is simultaneously supported by two symmetrical turning supporting plates 21 on the two turning shafts 2; through two symmetrical turning supporting plates 21 supports an item 5 to make the support more stable, and the item 5 can fall onto the receiving plate 4 in a balanced manner.

[0042] In this embodiment, preferably, two turning supporting plates 21 are fixedly installed on each turning shaft 2, and the angle between the two turning supporting plates 21 is 90°, 120° or 180°. In actual production , with 180 ° as the preferred; increasing the turnover supporting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com