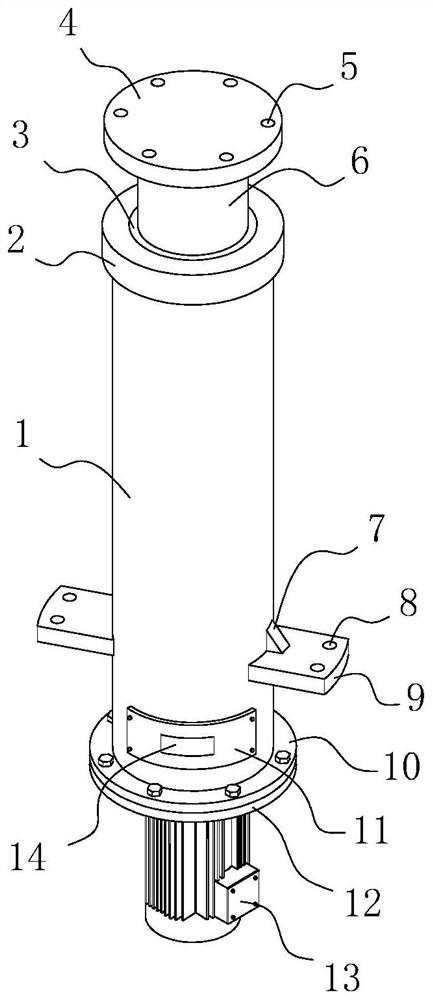

Self-locking device for lifting structure of mining machinery

A lifting structure and self-locking device technology, which is applied in the direction of lifting devices, transmission devices, mechanical equipment, etc., can solve the problems of lengthening, affecting the service life of servo motors, and damage to servo motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

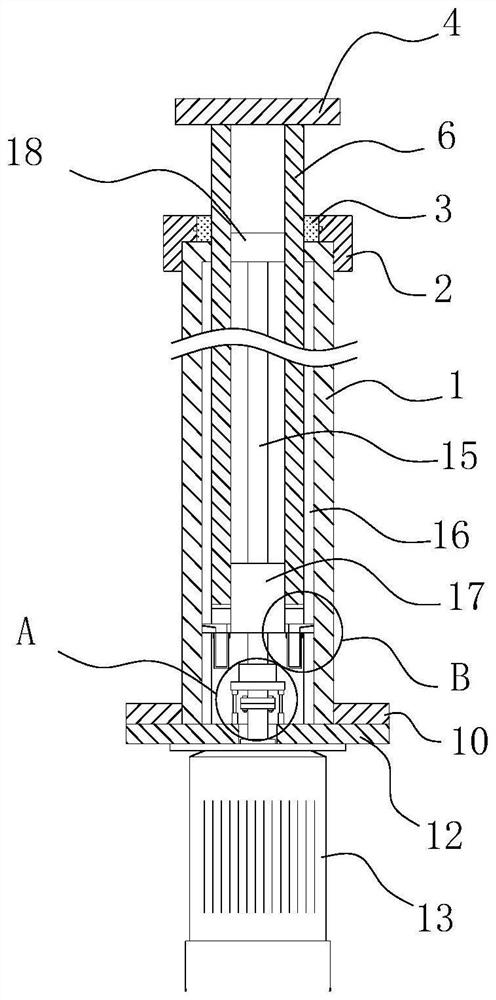

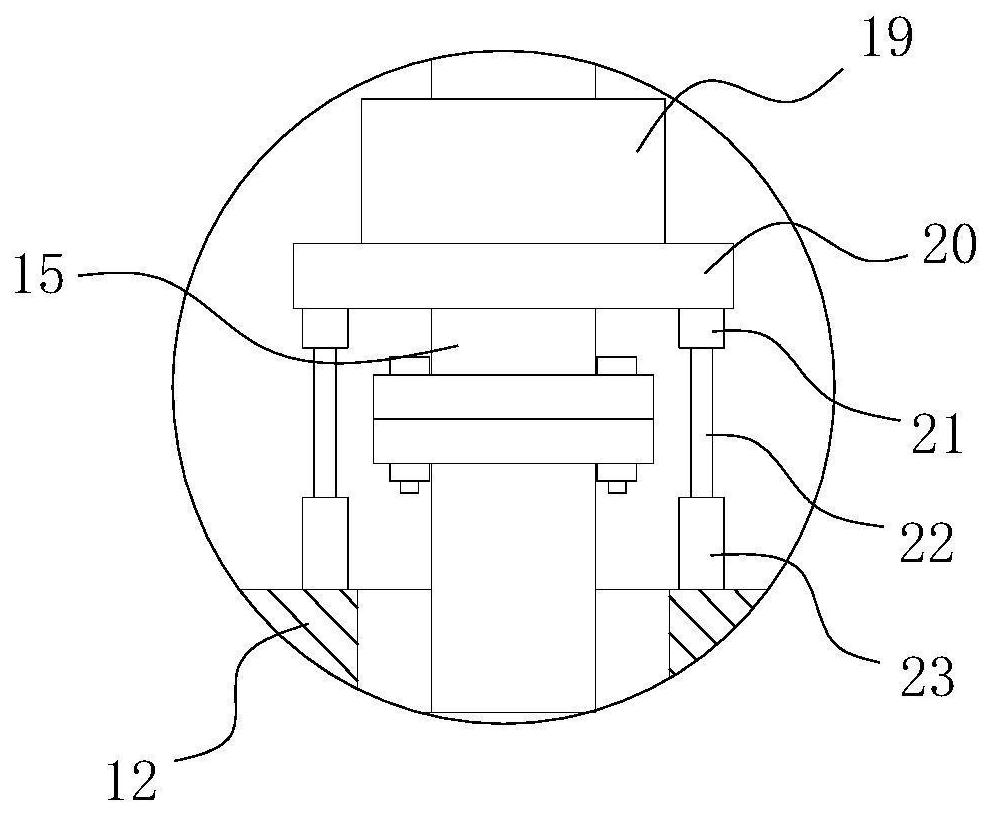

[0040]Specific embodiments: the bolts of the fixing connecting plate 9 are installed at the required position through the insertion hole 8 to complete the fixing of the position of the connecting plate 9, that is, the position of the cylinder 1 is limited, and the connecting plate 4 is used to connect the inner cylinder 6 with The components that need to be driven are connected, and the servo motor 13 is controlled by PLC to rotate forward or reverse, and then the ball nut pair 17 converts the rotary motion of the screw rod 15 into linear motion and drives the inner cylinder 6 to move in the cylinder 1, thereby achieving lifting At the same time, the ball nut pair 17 drives the sliding block 24 to slide along the sliding groove 16, and the sliding block 24 scrapes the dust attached to the inner surface of the sliding groove 16 into the groove 25 during the sliding process, and then falls into the groove 25 The dust inside slides along the inclined surface of the inner bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com