Deicing device for power transmission line

A transmission line and electric power technology, which is applied in the direction of electromechanical devices, cable installation, electric components, etc., can solve the problems of high cost and difficulty of deicing, tower collapse, power interruption, etc., and achieve better deicing effect and convenient movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

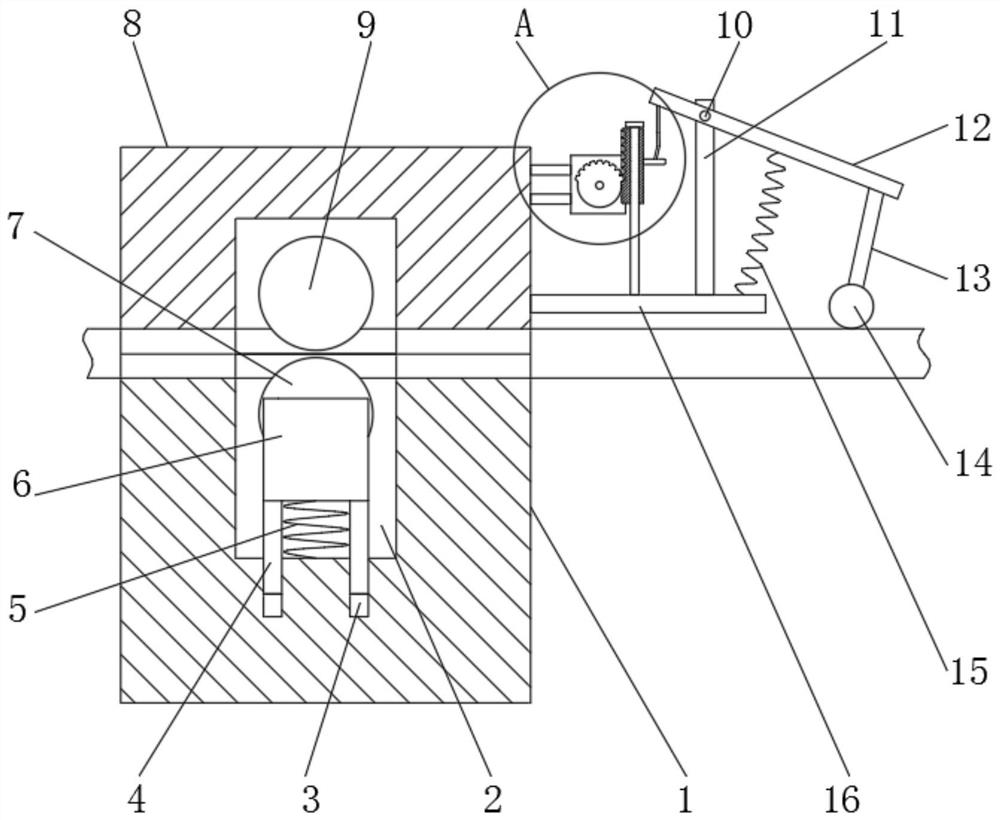

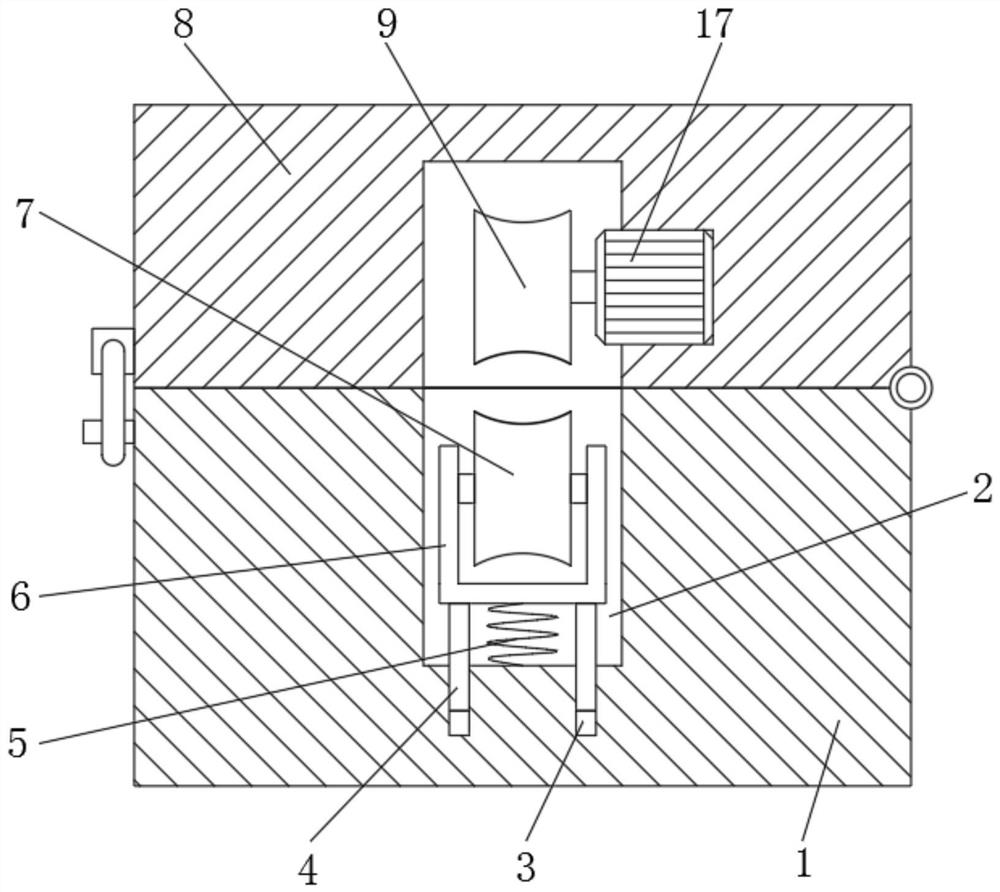

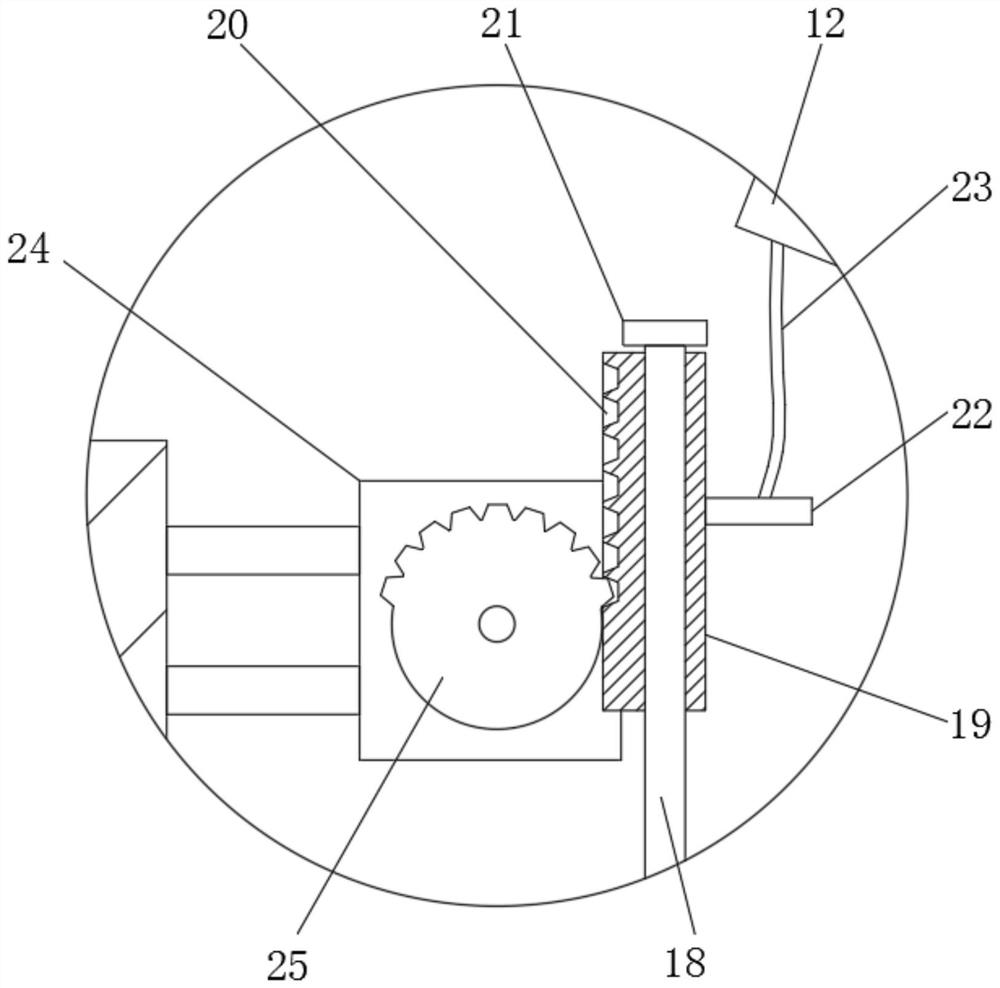

[0027] refer to Figure 1-4 , a deicing device for power transmission lines, including a lower fixing base 1 and an upper fixing base 8, the lower fixing base 1 and the upper fixing base 8 are connected by hinge rotation, and the buckle on the upper fixing base 8 and the The card seats on the lower fixing seat 1 are interlocked, the top outer wall of the lower fixing seat 1 is provided with a mounting groove 2, and the bottom inner wall of the mounting groove 2 is provided with a limiting groove 3, and the inner wall of the limiting groove 3 is slidably connected with a slide bar 4 , and the top outer wall of the slide bar 4 is fixedly connected with the ear seat 6, the inner wall of the ear seat 6 is connected with the roller 7 through bearing rotation, the bottom inner wall of the installation groove 2 is fixedly provided with the first spring 5, and one end of the first spring 5 and The bottom outer wall of the ear seat 6 is fixedly connected, and the bottom outer wall of t...

Embodiment 2

[0033] refer to Figure 5 , a deicing device for power transmission lines. Compared with Embodiment 1, this embodiment also includes a universal ball 26 on one side of the outer wall of the lower fixing seat 1, and the outer wall of the universal ball 26 passes through the third The spring 27 is connected with a vibrating block 28, and the outer wall of one side of the vibrating block 28 is provided with ice crushing teeth 29 distributed equidistantly, which can break the icicles and facilitate the movement of the device.

[0034] A cavity is provided inside the vibrating mass 28 , and a vibrating motor 30 is provided inside the cavity.

[0035] Working principle: when in use, since the vibration block 28 and the universal ball 26 are connected by the third spring 27, when the vibration motor 30 is driven to work, the vibration block 28 can be driven to vibrate on the universal ball 26, and through the vibration block 28 The ice crushing teeth on the top can crush the icicles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com