Assembly type door shaft mounting structure

An installation structure and assembly technology, applied in door/window fittings, building structures, wing leaf parts, etc., can solve problems such as door shaft sinking, fire door opening inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

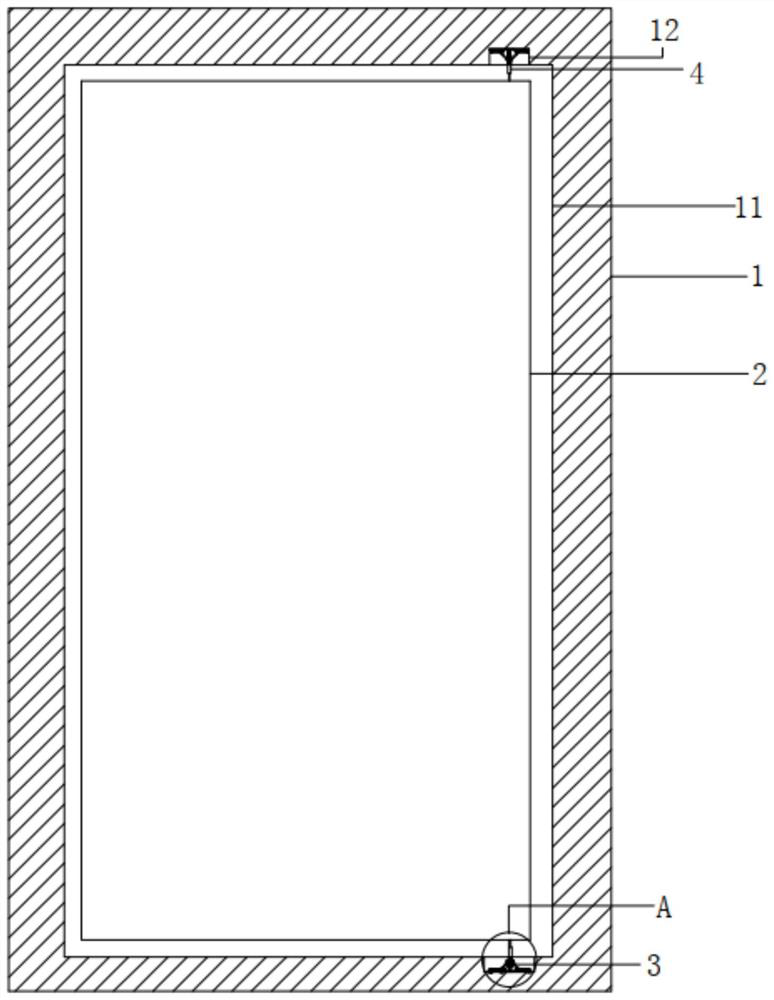

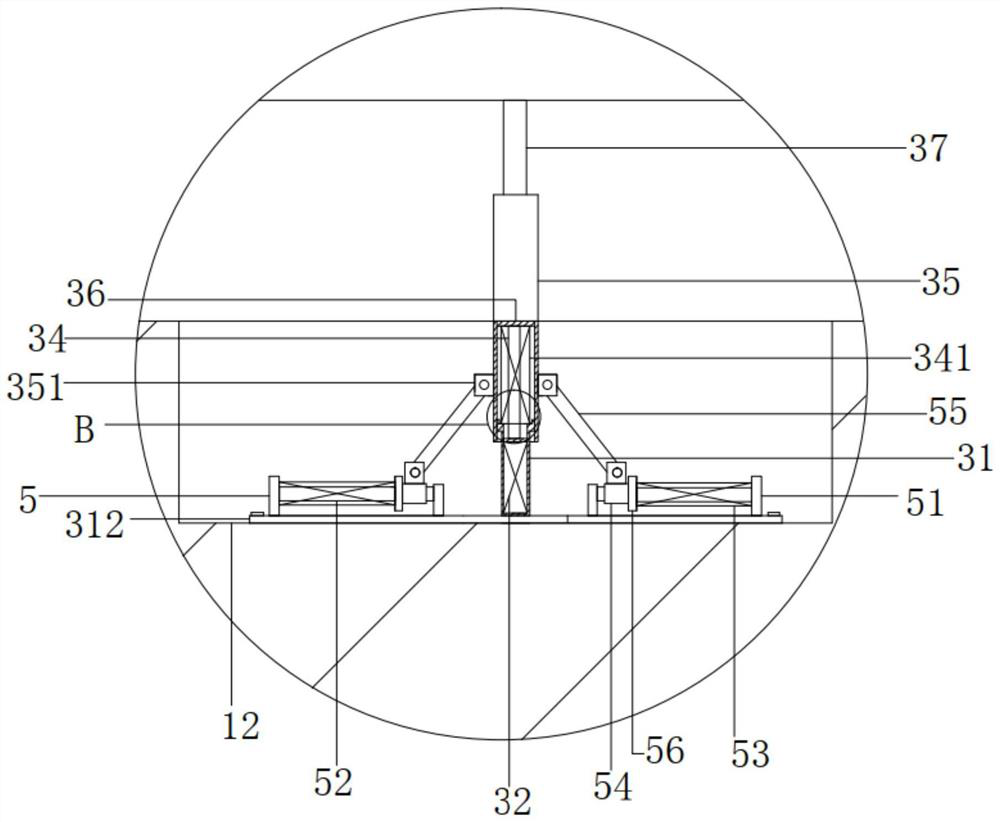

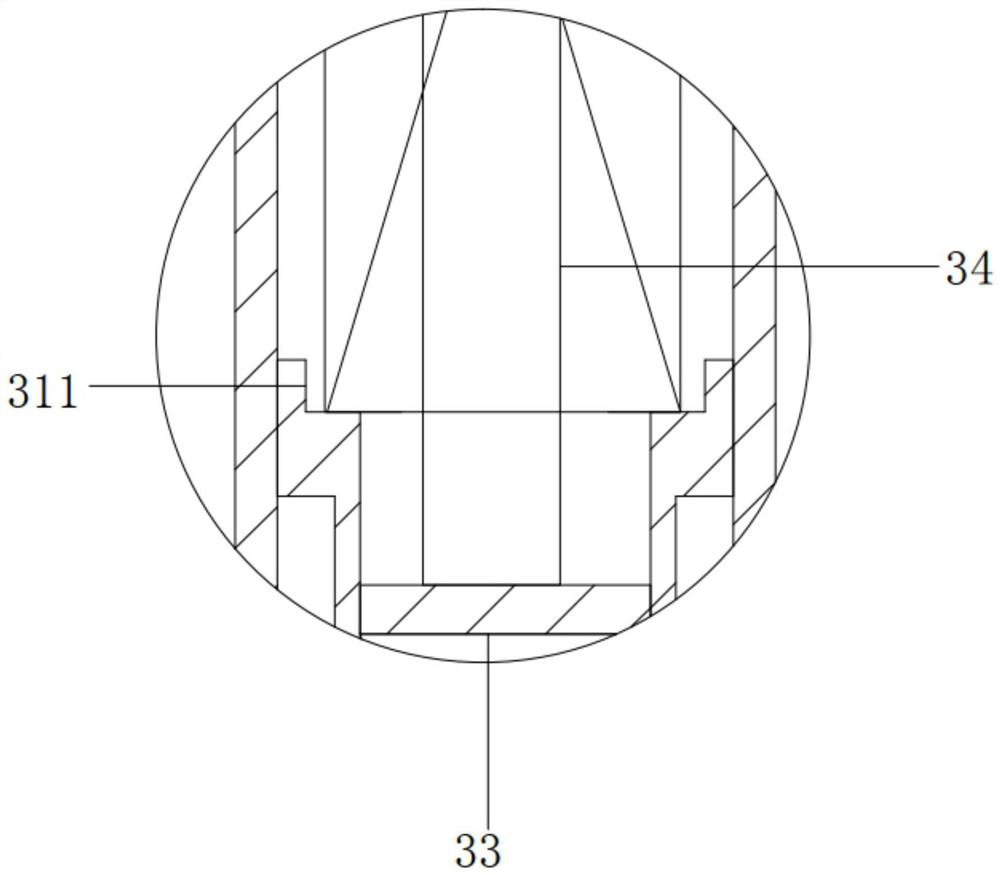

[0023] see Figure 1 to Figure 3 , the figure shows a prefabricated door shaft installation structure provided by Embodiment 1 of the present invention, mainly provided with a wall 1 and a door panel 2, the wall 1 is provided with an installation hole 11, and the door panel 2 is rotatably connected to the installation hole 11 Inside, the top of the mounting hole 11 is provided with a first rotating part 3, the bottom of the mounting hole 11 is provided with a second rotating part 4, one end of the door panel 2 is rotatably connected to the first rotating part 3, and the other end of the door panel 2 is rotatably connected to the On the second rotating part 4, the first rotating part 3 has the same structure as the second rotating part 4, the first rotating part 3 includes a first connecting rod 31, a first spring 32 is arranged in the first connecting rod 31, and a first spring 32 A support plate 33 is provided, a support rod 34 is installed on the support plate 33, one end of...

Embodiment 2

[0030] see Figure 1 to Figure 3 , the figure shows an assembled door shaft installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the support rod 34 A second spring 341 is sleeved, one end of the second spring 341 is connected to the first baffle 36, and the other end of the second spring 341 is connected to the first connecting rod 31; the first connecting rod 31 is provided with a stepped surface 311 , the end of the second spring 31 is connected to the stepped surface 311 . Through the setting of the above structure, the second spring 341 can play a buffering role, further preventing the door from sinking axially into the wall.

Embodiment 3

[0032] see Figure 1 to Figure 3 , the figure shows an assembled door shaft installation structure provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first connecting rod The bottom of 31 is connected with mounting plate 312, and mounting plate 312 is provided with two supporting parts 5, and two supporting parts 5 are symmetrically arranged on the opposite sides of first connecting rod 31; block 51, a slide bar 52 is provided between the two supporting blocks 51, a third spring 53 is sleeved on the slide bar 52, a slide block 54 is slidably connected on the slide bar 52, and the slide block 54 is connected to the end of the third spring 53 In contact, the slider 54 is connected with a second connecting rod 55 , and the opposite end of the second connecting rod 55 is connected with the first rotating shaft 35 . Through the setting of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com