Glass fiber reinforced plastic cable bridge and cover plate fastening device thereof

A cable bridge and fastening device technology, applied in the direction of electrical components, etc., can solve the problems of poor fastening effect, cumbersome disassembly and assembly, etc., and achieve the effect of good fastening effect and convenient disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

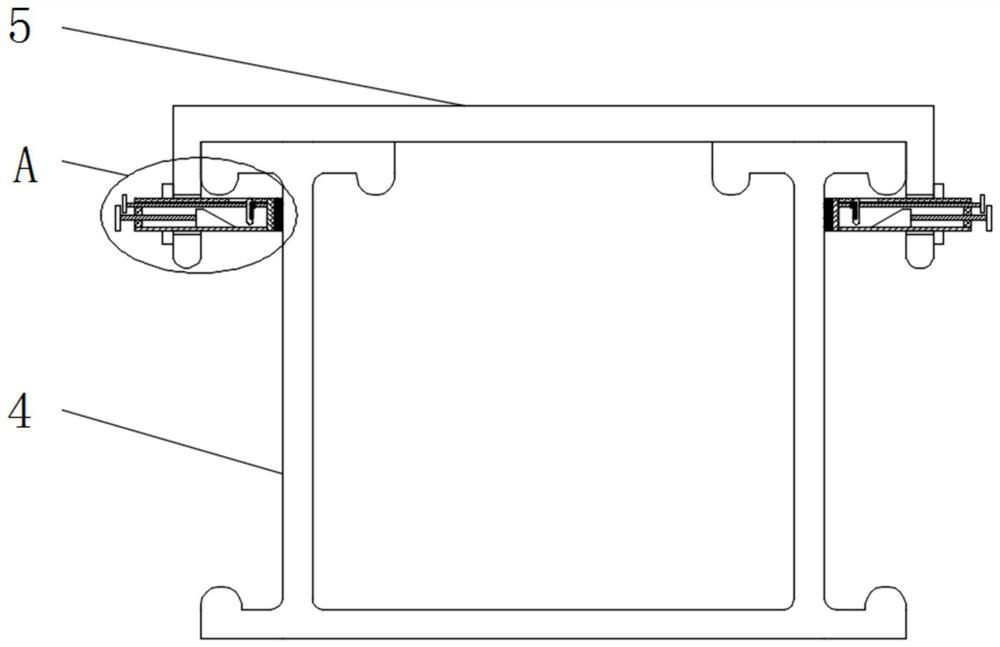

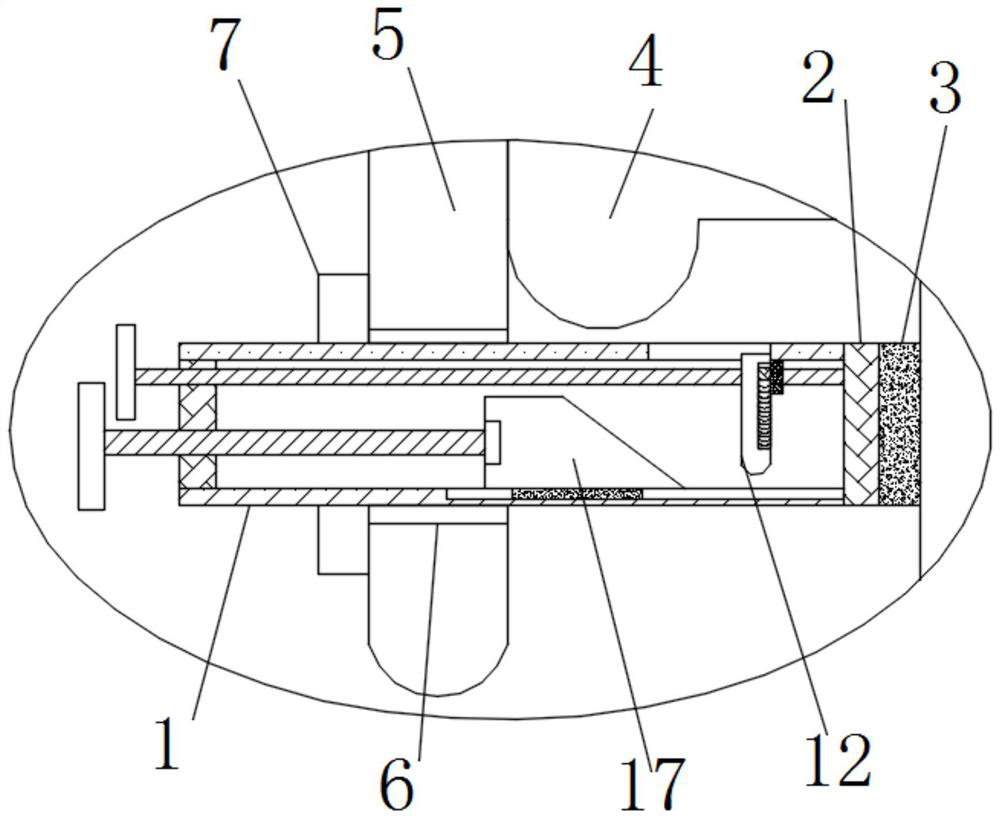

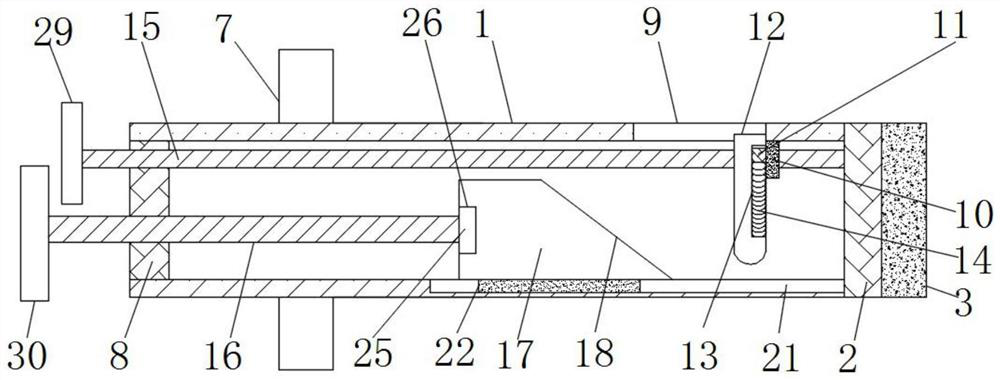

[0031] see Figure 1-7 According to an embodiment of the present invention, a fastening device for a FRP cable tray and its cover plate includes a sleeve 1, and one end of the sleeve 1 is fixedly connected with a sealing plate 2, and the sealing plate 2 is far away from the One end of the sleeve 1 is fixedly connected with a rubber pad 3, the rubber pad 3 is in contact with the cable tray 4, the top of the cable tray 4 is provided with a cover plate 5, and the side wall of the cover plate 5 is provided with a through hole 6, The sleeve 1 runs through the through hole 6, the outer surface of the sleeve 1 is threaded to the limit ring 7, and the outer wall of the sleeve 1 is provided with lines that can be threaded to the limit ring 7;

[0032] One end of the sleeve 1 away from the sealing plate 2 is fixedly connected with a sealing plate 2 8, and a movable opening 9 is formed on one side of the sleeve 1, and a movable opening 9 is arranged inside the sleeve 1 near the movable o...

Embodiment 2

[0036] see Figure 2-4 , the inner wall of the sleeve 1 is opened with a limiting slot 19 near the movable block 10, and the movable block 10 is fixedly connected with a limiting block 120 near the limiting slot 19, and the limiting block 120 Located in the limiting groove one 19 and matched with the limiting groove one 19, the limiting piece one 20 and the limiting groove one 19 can limit the movable block 10 so that the movable block 10 does not follow the movement of the screw rod one 15. Rotating and moving, the inner wall of the sleeve 1 is provided with a limiting groove 2 21 near the pushing block 17, and the pushing block 17 is fixedly connected with a limiting block 2 22 near the limiting groove 21, and the limiting Block two 22 is positioned in described limit groove two 21 and matches with described limit groove two 21, and limit block two 22 and limit groove two 21 can carry out position-limiting operation to pushing block 17, avoid pushing block 17 due to Screw I...

Embodiment 3

[0038] see image 3 with Image 6, the movable mechanism one includes a round hole one 23 and a bearing one 24, the surface of the sealing plate one 2 has a round hole one 23, the inner wall of the round hole one 23 is fixedly connected with a bearing one 24, and the screw rod one 15 Fixedly connected with the inner wall of the bearing one 24, the moving mechanism one can realize the flexible connection between the screw rod one 15 and the sealing plate one 2, the moving mechanism two includes the bearing two 25 and the round hole two 26, and the pushing block 17 is far away from the One end of the moving block 12 has a circular hole 26, the inner wall of the circular hole 26 is fixedly connected with a bearing 25, the screw 16 is fixedly connected with the inner wall of the bearing 25, and the movable mechanism 2 can realize screw Active connection between two 16 and the pushing block 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com