Parallel mechanism with composite sliding telescopic rod

A telescopic rod and parallel technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of being easily damaged and unstable, and achieve the effect of expanding the working space, simplifying the assembly, and reducing the number of branches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The parallel mechanism provided by the present invention including the composite sliding telescopic rod will be described in detail below in conjunction with the accompanying drawings.

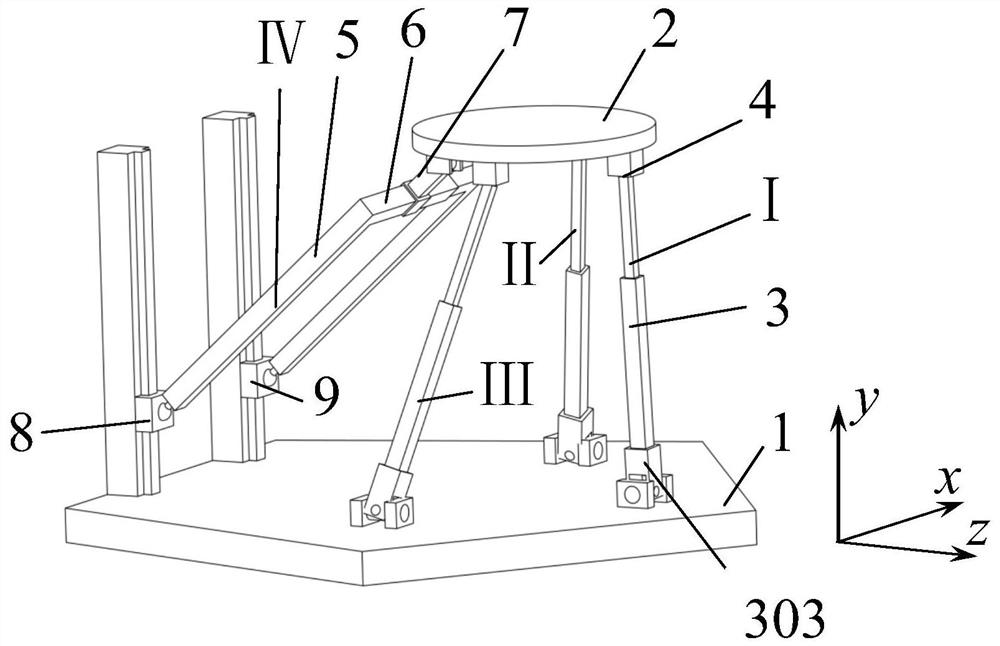

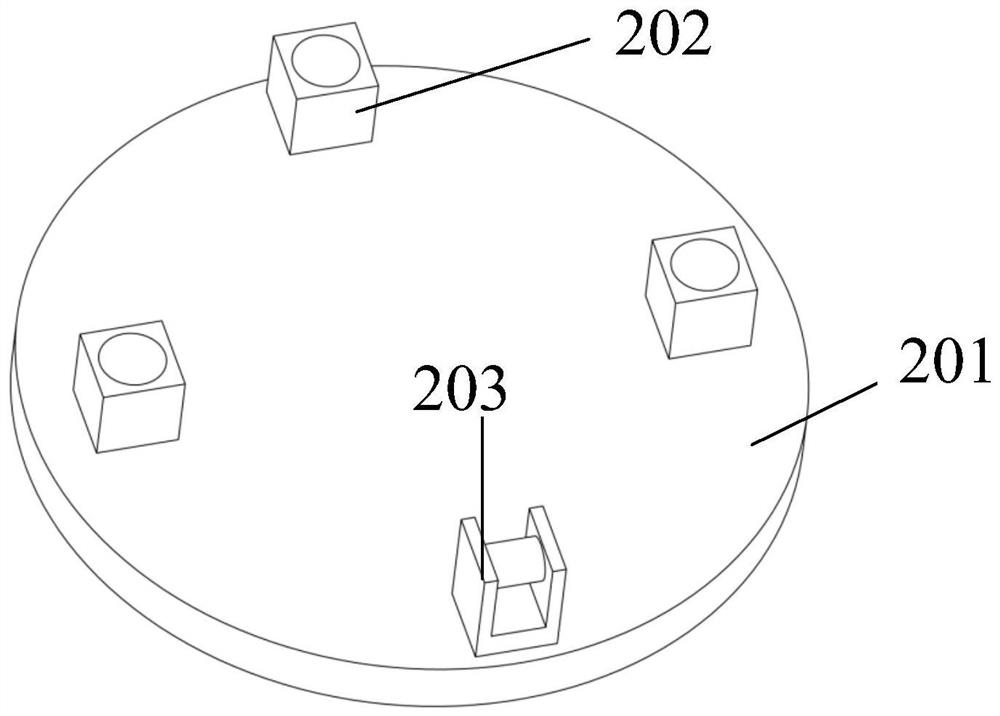

[0027] Such as figure 1 — Figure 10 As shown, the parallel mechanism provided by the present invention including the sliding composite telescopic rod includes a fixed platform 1, a moving platform 2, a first branch chain I, a second branch chain II, a third branch chain III and a fourth branch chain IV;

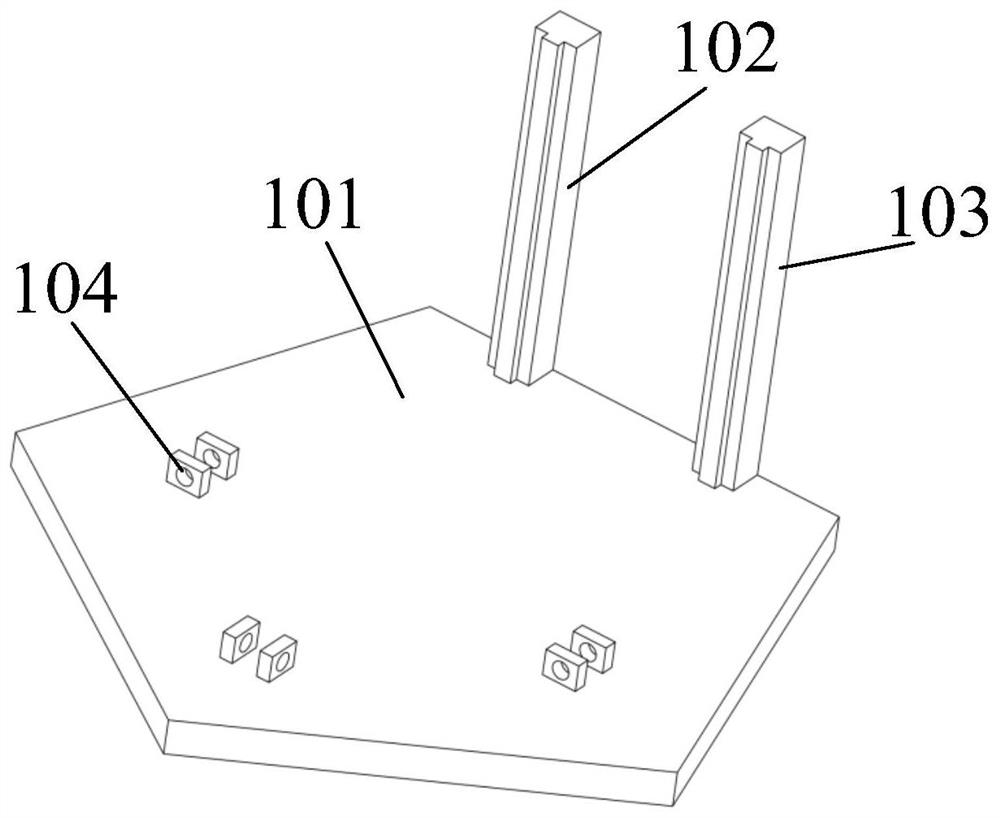

[0028] Wherein, fixed platform 1 comprises base 101, first guide rail 102, second guide rail 103 and three first Hooke hinge supports 104; Wherein, base 101 is fixed on the ground; Three first Hooke hinge supports 104 are The character shape is installed on one side of the surface of the base 101; the first guide rail 102 and the second guide rail 103 are linear guide rails, and the lower ends are symmetrically fixed on the other side of the surface of the base 101 at intervals, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com