A parallel mechanism containing a binding and composite driver chain

A technology of driving branch chains and parallel connections, which is applied in the directions of manipulators, program-controlled manipulators, and manufacturing tools. Isotropic performance, improved motion stability, and increased load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

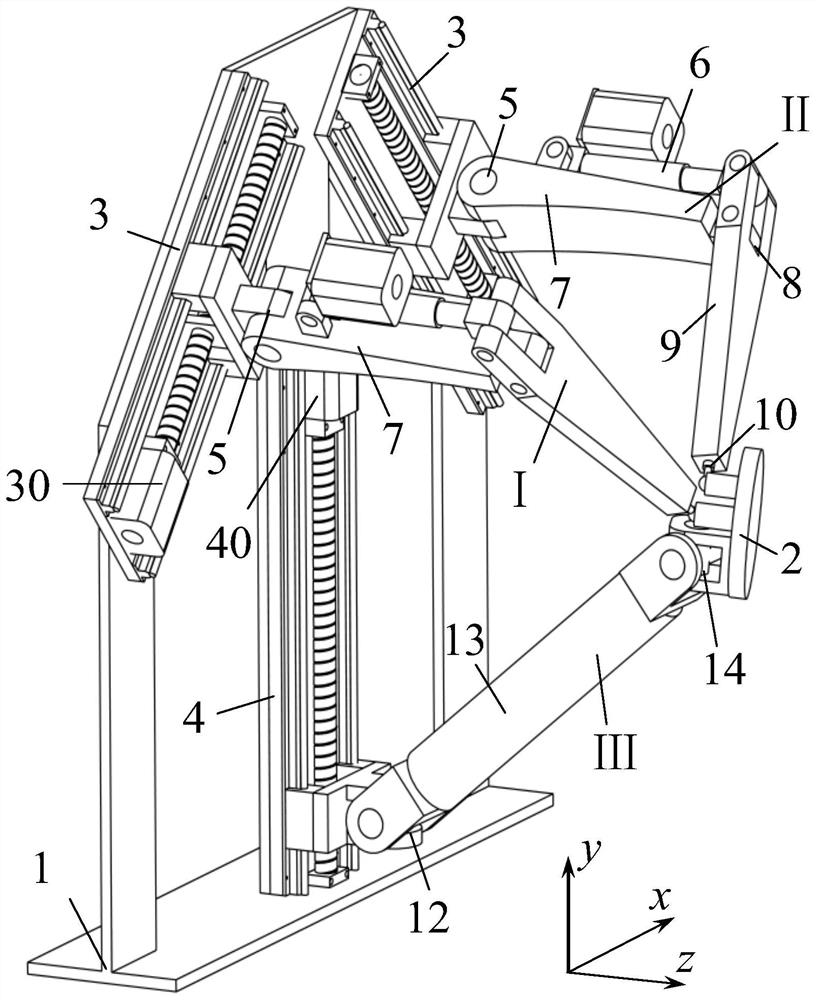

[0025] The parallel mechanism provided by the present invention with just-constrained and compound drive branches will be described in detail below with reference to the accompanying drawings.

[0026] like figure 1 — Figure 7 As shown, the parallel mechanism provided by the present invention containing just constraint and compound drive branches includes a fixed platform 1, a movable platform 2, a first branch I, a second branch II and a third branch III;

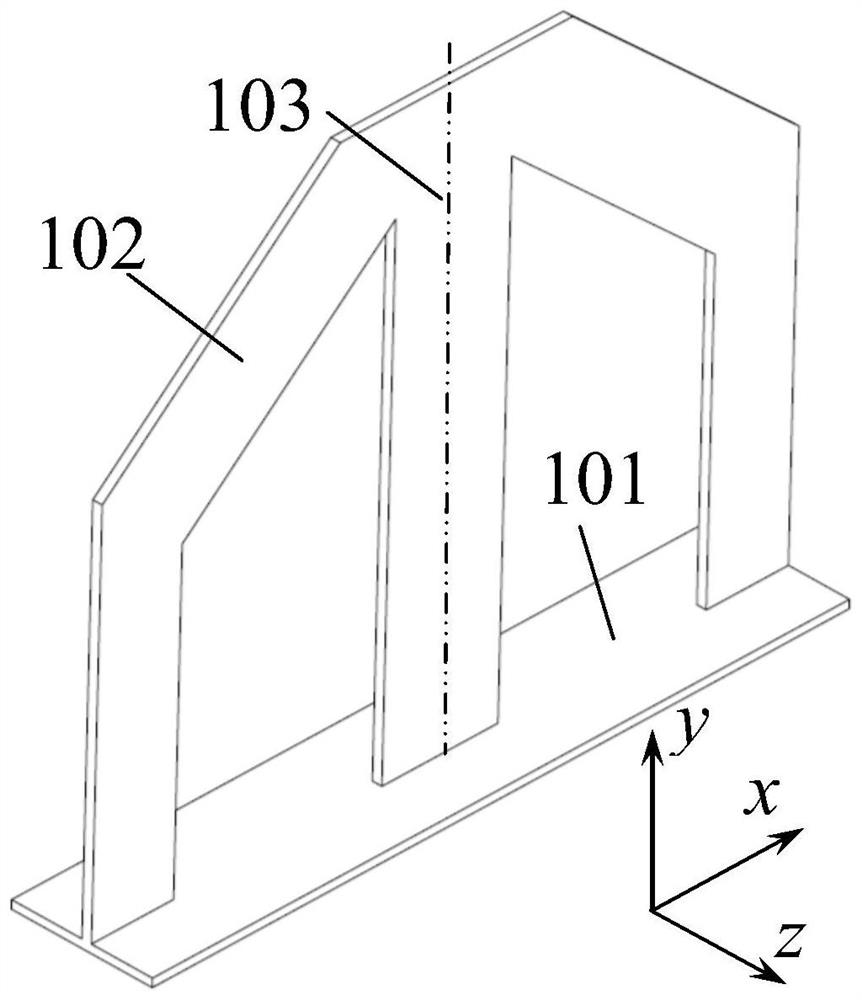

[0027] Wherein, the fixed platform 1 includes a base 101 fixed on the ground and a frame 102 vertically fixed on the base 101;

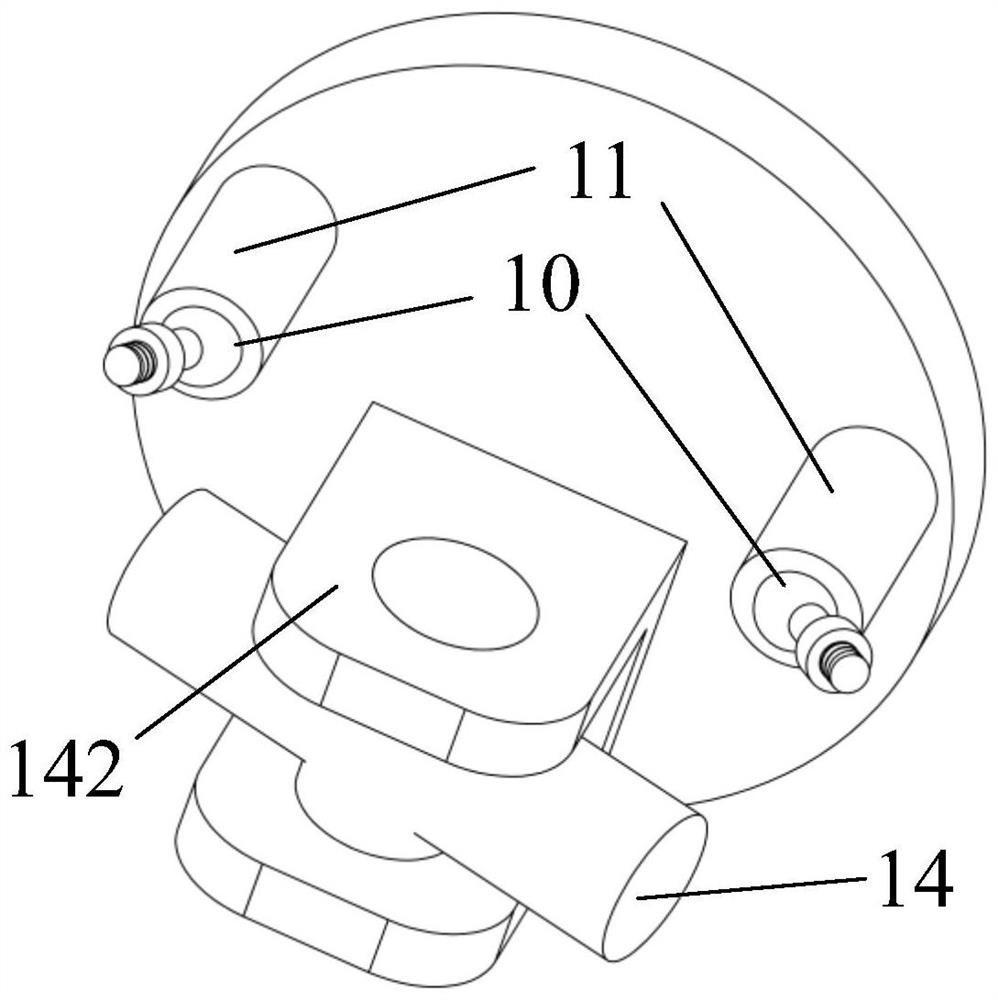

[0028] A second Hooke hinge support 142 and two spherical hinge supports 11 are fixed on one end surface of the moving platform 2;

[0029] The first branch chain I and the second branch chain II are both composite drive branch chains, and each composite drive branch chain includes a first moving component 3 , a first connecting rod 7 , a second connecting rod 9 , a first driving component 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com