Flexible gripper and manipulator

A technology of manipulators and claws, applied in the field of industrial robots, can solve problems such as large structures and immutable action programs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

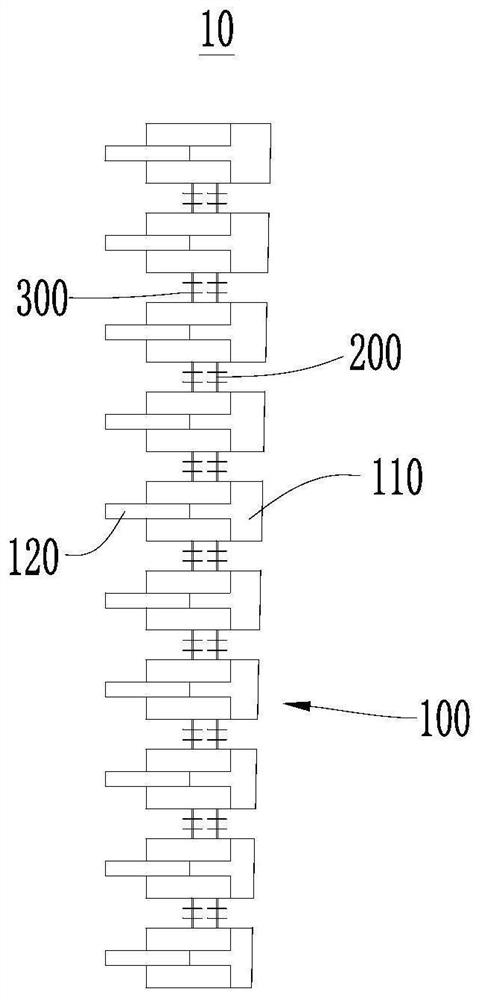

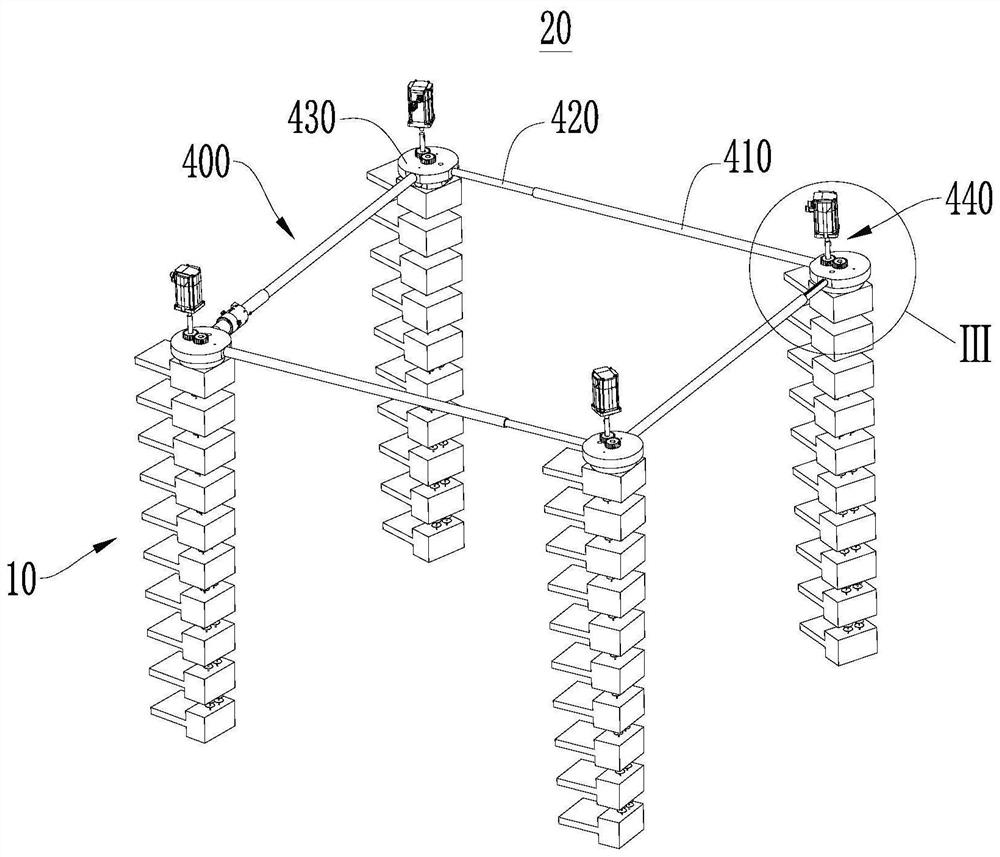

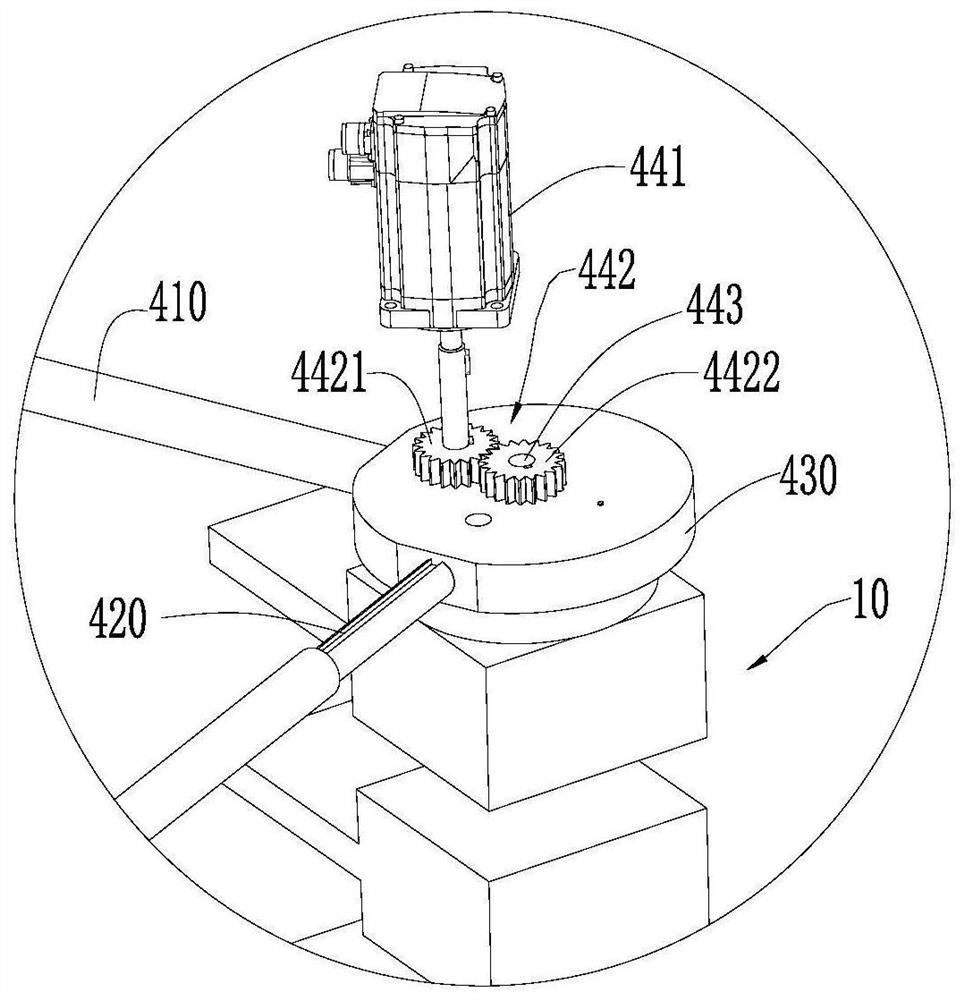

[0030] Please refer to figure 1 , this embodiment provides a flexible gripper 10, the flexible gripper 10 includes a plurality of gripper units 100 and a controller. Each gripper unit 100 includes a coil, the controller is electrically connected to the coil, and the controller is configured to control the direction of the coil. A plurality of gripper units 100 are connected by a flexible tube 200 . When the coil is energized in the forward direction, two adjacent gripper units 100 attract or repel each other. A coil is provided on the gripper unit 100, and when the coil is energized, according to the principle of electromagnetism, the coil will generate N and S magnetic poles. The purpose of controlling the polarity can be achieved by controlling the direction of the current in each gripper unit 100 by the controller. When the direction of the current passing through the coils of the adjacent gripper units 100 is opposite, the polarities generated on the two opposing surfac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap