Rotating type pouring machine for casting machining

A rotary, pouring machine technology, applied in the control of pouring molten metal from a ladle, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency, work intensity impact, worker physical safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

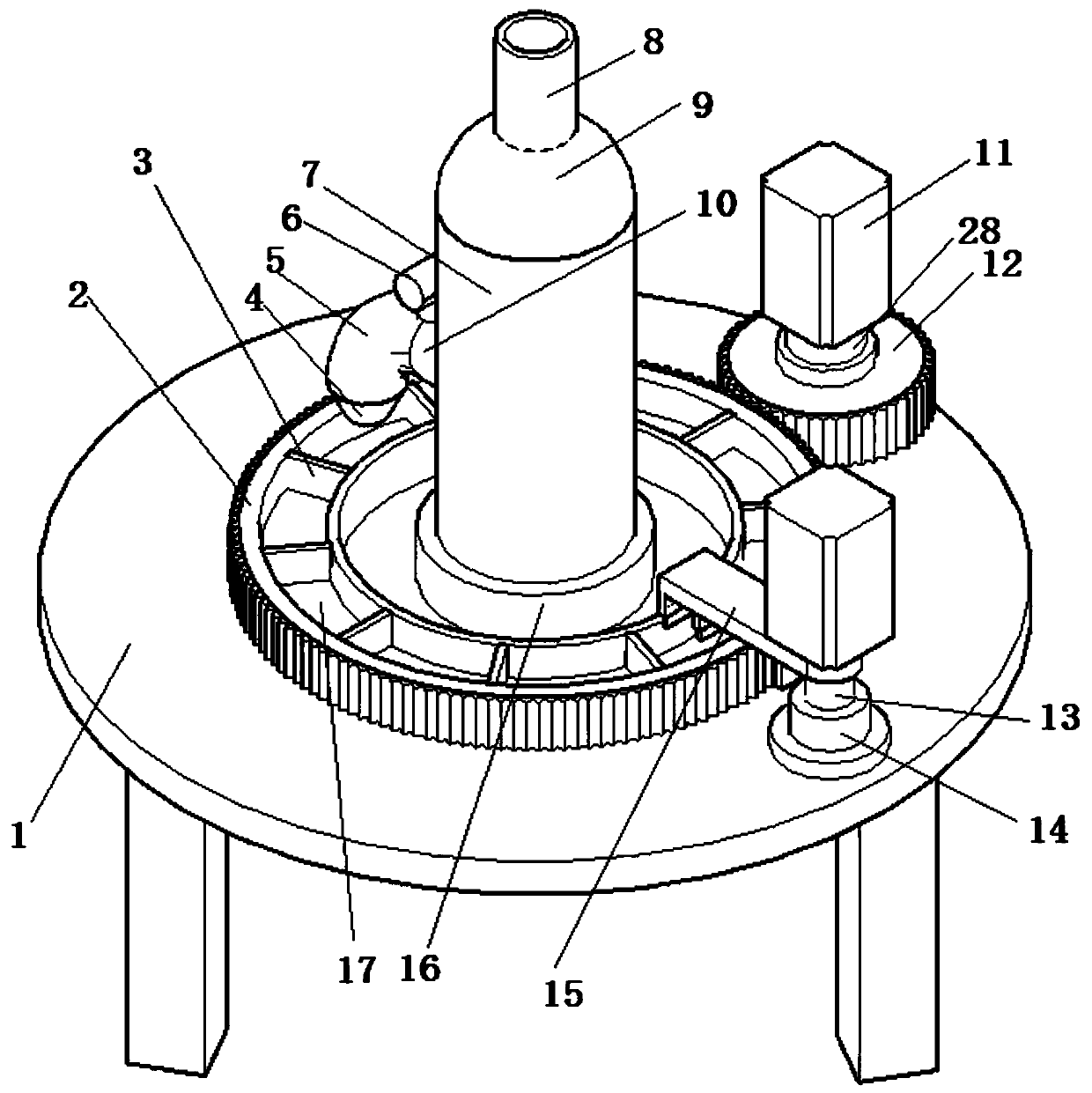

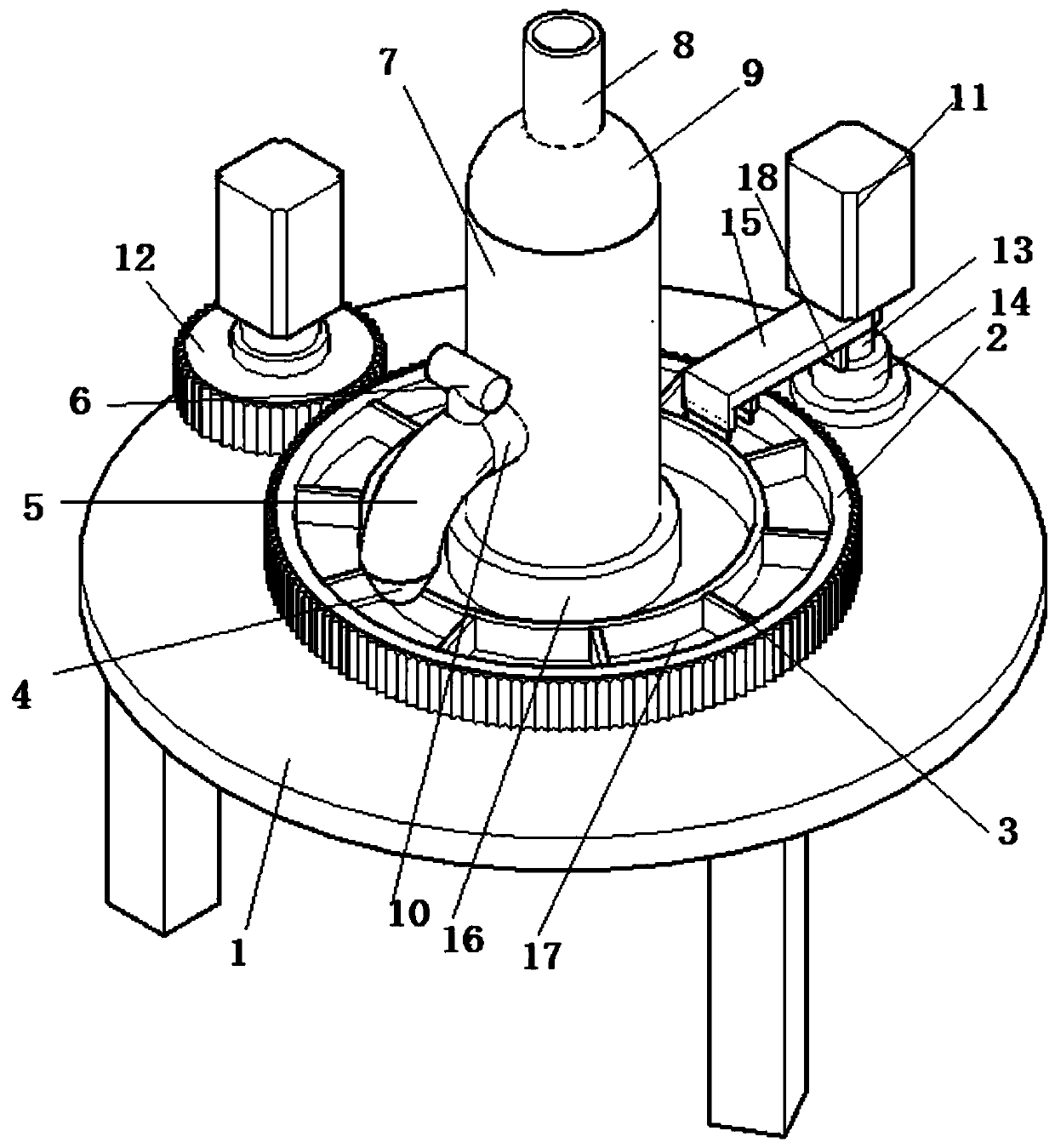

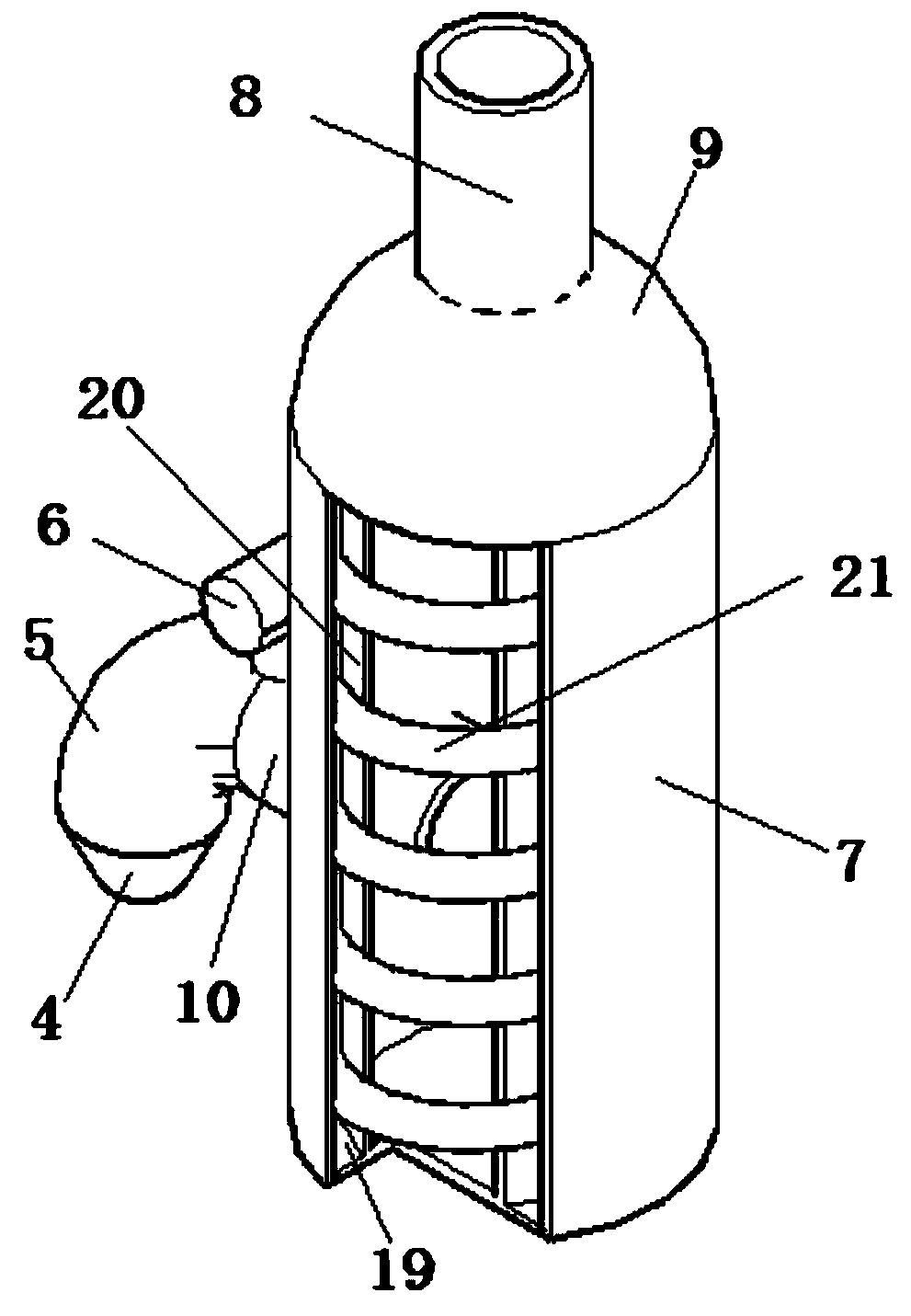

[0022] Such as Figures 1 to 7 As shown, this embodiment provides a rotary pouring machine for casting processing, including a disc-shaped worktable, on which a toothed disc driven by a drive mechanism is provided, and the toothed disc is located on its upper surface An annular groove is opened, and the interior of the annular groove is divided into several molding box storage grooves by a partition plate. A molten iron containing component is fixedly installed on the center of the disc-shaped workbench through a base. One side of the molten iron containing component There is a pouring assembly communicating with it, and a gripping manipulator driven by a motor is fixed at a position opposite to the pouring assembly on the disc-shaped workbench. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap